ANCA will showcase its latest innovations at the GrindingHub show in Stuttgart in Hall 10 Stand C51. “Automation and digitization are at the centre of this display. We are showing Industry 4.0 solutions that fit with the context and targets of our customers, be it small, mid-sized or larger companies,” says Martin Winterstein, Sales Manager for Europe.

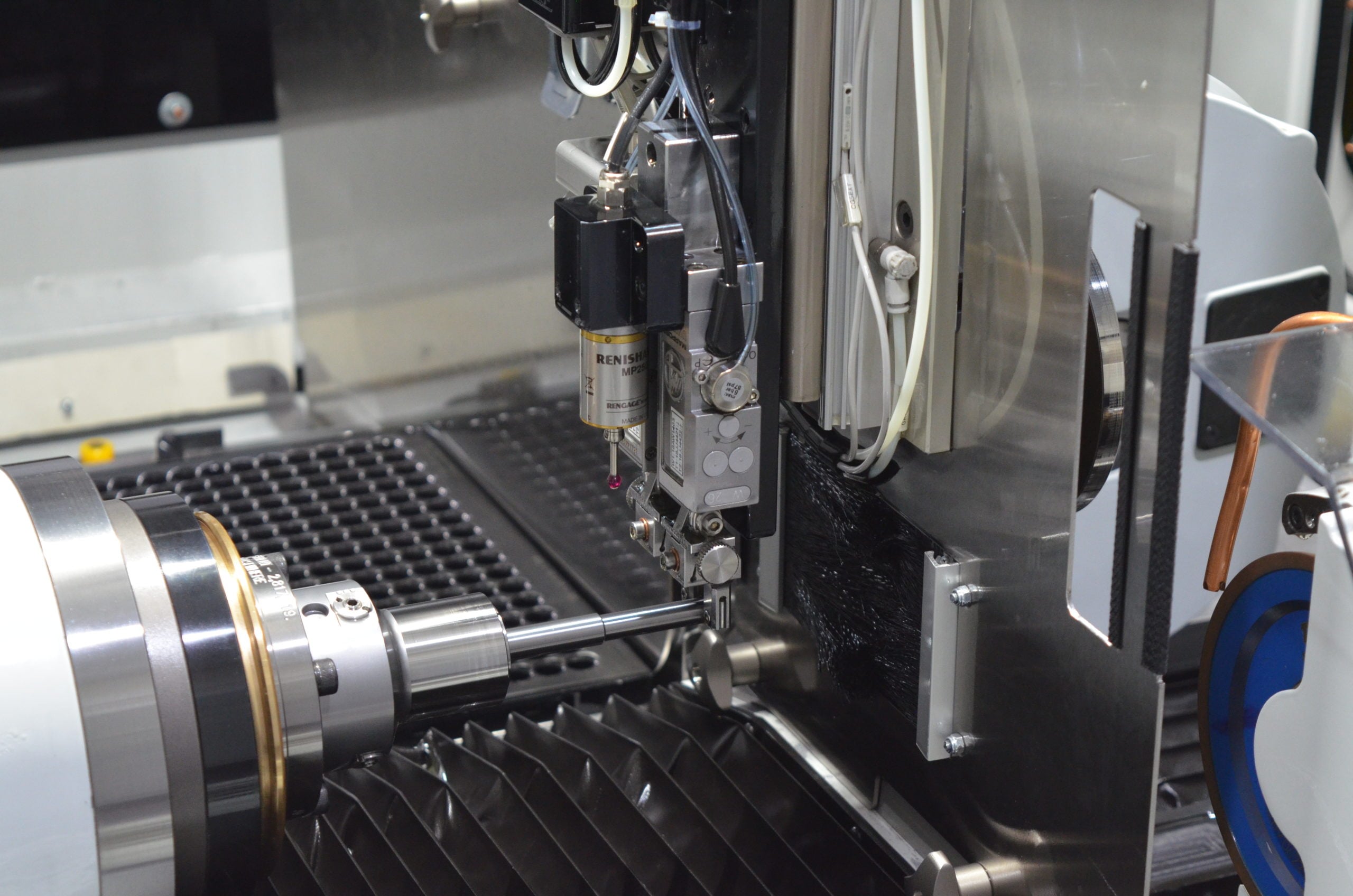

The company will launch its CPX in-process OD measurement system, a quality control system that monitors and controls the OD of ground blanks within batch production. Batch grinding on a CPX with high material removal rates and to tight tolerances is a basic function of the machine, the OD measurement system takes it further by utilising the SPC feature that comes standard with the OD software.

ANCA’s Integrated Manufacturing System (AIMS) streamlines manufacturing and connectivity. With ANCA and AIMS, customers can achieve continuous, unattended production that reduces non-productive machine time with smart automation that offers connectivity across the whole factory. The technology considers a factory as a single machine, rather than separating it into different elements of design, blank preparation, grinding, laser marking, washing, packing and shipment. This concept brings together one ecosystem and builds it to be as efficient as possible.

The GrindingHub demo consists of the AutoSet preparation station, as the main operator interface. Jobs scheduled for production are downloaded through the AIMS server to the AutoSet station and are prepared for production, pallets are loaded with blanks for automatic process and the AutoFetch AMR (Autonomous Mobile Robot) responsible for transfer between processes replaces operators carrying pallets or individual tools between machines. The AutoFetch robot will transfer full pallets with blanks to the respective grinder, pick up an individual tool from a grinder for out-of-process measurement and compensation and then pick a pallet of finished tools and transfer to finished goods.

ANCA will also show its RFID technology with the LaserUltra closed-loop measurement and barcode reader that will be demonstrated on the FX7 Linear platform. The FX7 Linear machine will also be fitted with a pop-up steady, AutoStick, auto wheel qualification and iView.

Driven by the automotive industry’s electrification and the general rise of e-mobility, the demand for skiving cutters has seen 30% year on year growth. The GCX Linear will provide a complete solution for producing skiving cutters, shaper cutters and the regrinding of hobs.