🎧Advanced digital manufacturing with AI-powered solutions

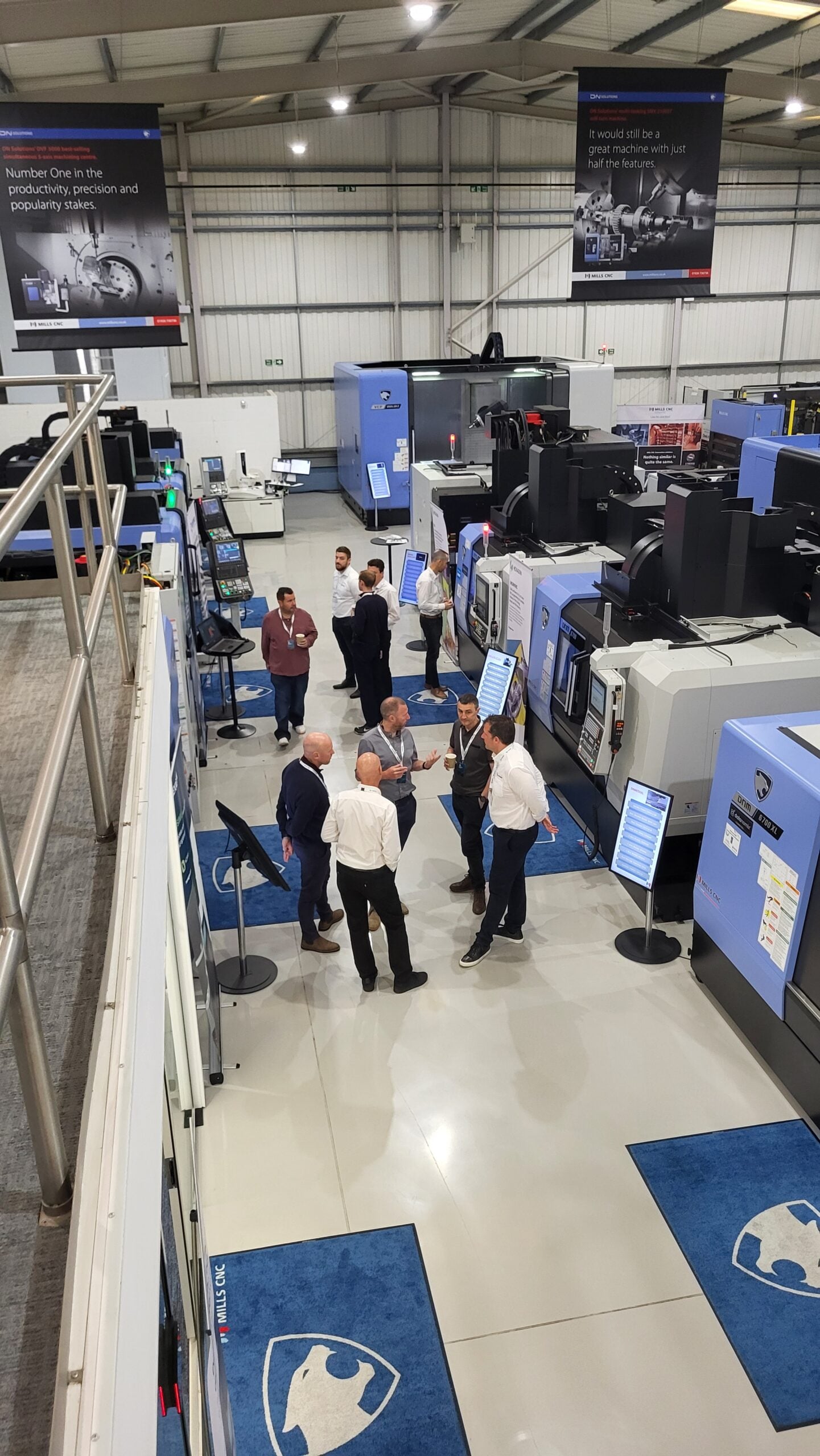

In July, we discussed our visit to the Hexagon event at Mills CNC, where Hexagon’s Nexus platform was shown. The event also alluded to how Pro Plan AI demonstrated 70 to 75% programming productivity improvements. With such impressive statistics and other products on show, we wanted to dig a little deeper into the production intelligence solutions. By Rhys Williams

Real-Time Production Intelligence with Datanomics

Zoltan Tomoga, Product Manager for Hexagon’s Production Software Business Unit, detailed Datanomics’ comprehensive approach to production monitoring, emphasising its zero-operator-input design that sets it apart from competing solutions. “Most machine monitoring solutions require the operator to tell the solution why the machine is stuck. The problem is, if you’ve got a big list of reasons, operators will often select the first one, always a broken tool, as opposed to the coolant or whatever. Whereas Datanomics is completely no operator input.”

The system’s connectivity architecture enables comprehensive data collection without disrupting workflow. “Each machine has an Ethernet port that will connect to a network, and then you can pull information off of it, as well as push information to it. With our CAM software, we typically push the program through the Ethernet,” Zoltan noted.

Datanomics serves three distinct user categories with targeted interfaces designed for specific operational needs. For management, ‘you are mainly interested in OEE. You want to see how much of your shop is utilised.’ The primary focus targets shop floor managers who require intelligence: “Every morning at six, we send out the coffee cup report, so when they arrive, the night shift is still there. They can open a report, see what’s happened and talk to relevant operators.”

The Factory Mate AI enhancement offers instant problem diagnosis capabilities, enabling immediate corrective action. “A shop floor manager just arrived at the factory. There was one machine which didn’t perform very well. They hit the factory mate icon, and it will give them the top three downtime events. In this case, we were waiting for an operator. That was the second one as well, and the machine was stuck,” Zoltan demonstrated.

For process engineers requiring deeper analysis, Datanomics offers comprehensive historical data capabilities that facilitate continuous improvement initiatives. “In EdgeCAM, if I generate an NC code, I can put what EdgeCAM says is going to be the cycle time. However, if the feed override, or the rapid wasn’t set to 100%, it might start to differ. The target for one part was 56 minutes, but we are actually running on 59 minutes recently. However, Datanomics thinks we could run that part in 45 minutes and improve on efficiency,” Zoltan explained, demonstrating how the system identifies specific optimisation opportunities.

Tooling insights provide strategic procurement intelligence. “You will see which tool you use the most, and make a decision if you want to adjust speeds and feeds on that tool.”

Benchmarking Progress: Quantifying Industry Digital Maturity

The benchmarking initiative previously discussed in MTD May Issue with Jason Walker, Hexagon’s VP of General Manufacturing, has collected substantial industry data over twelve months, revealing concerning gaps in digital adoption across manufacturing operations.

The results confirmed extensive manual processes that create competitive disadvantages. “More than half of manufacturers are still using a manual process, which typically involves whiteboards and Excel spreadsheets and a lot of manual planning,” Walker revealed. Most of the upstream processes for winning work, like quoting and planning, are very much done manually.”

Production intelligence gaps create significant profitability challenges for manufacturers who are unable to track actual versus planned performance. “Understanding the utilisation of the machines on the shop floor probably comes all the way back to the quoting process and understanding the profitability of your business, because if you’re quoting that a part is going to take two hours to machine, and you have no traceability to see who did that part or whether that batch of 1000 parts did actually take two hours each. Or did they run at two hours and five minutes, which makes a large difference over the batch,” Walker explained.

The competitive implications of slow processes are significant for business sustainability. “Ultimately, many of these companies, when they are winning the work, it’s because they’ve under-quoted on a job which further erodes their profitability,” Walker observed.

External pressures are accelerating transformation requirements. “Lockheed Martin has a model-based enterprise playbook for suppliers. Lockheed are actively saying to their supply chain, if you aren’t going to adopt these new technologies that are going to allow you to manage the digital thread through the digital models that we’re going to provide you with, then ultimately, you will be losing out on work in the future,” Walker shared, demonstrating how OEMs are making digital transformation mandatory.

Quantifying Digital Transformation Benefits

The event demonstrated how digital manufacturing solutions deliver measurable business improvements across multiple operational areas that justify investment through concrete returns. The integration of solutions presented in Part One—Nexus connectivity, Pro Plan AI programming acceleration, and Paperless Parts quoting automation—creates compounded benefits when combined with real-time production intelligence from Datanomics.

Pro Plan AI’s 70 to 75% reduction in programming time enables manufacturers to complete days of work in mere minutes while capturing institutional knowledge from experienced programmers. This capability, combined with Mills CNC’s DNX 2100 launch aimed at reducing setup time, exemplifies an industry-wide shift towards efficiency optimisation.

Paperless Parts transforms quote-to-cash cycles from week-long manual processes into 24 to 48 hour automated workflows, enabling customers to secure 25% more business through quicker response times. The platform removes resource constraints by alleviating quoting burdens from owners and managers.

Datanomics provides real-time production intelligence without requiring operator input. This enables shop floor managers to identify and resolve issues through immediate problem diagnosis and historical trend analysis. The system’s ability to compare target and actual cycle times reveals optimisation opportunities, such as identifying potential efficiency improvements.

The benchmarking data reveals that over half of manufacturers still rely on manual processes for critical business functions.

Looking Forward: Measuring Manufacturing’s Digital Future

The convergence of AI-driven programming, automated quoting systems, and real-time production intelligence generates combined benefits that surpass the capabilities of individual solutions. Manufacturers adopting comprehensive digital workflows can realise simultaneous enhancements in quote win rates, programming productivity, and production efficiency while tackling workforce challenges through knowledge capture and skills augmentation.

Hexagon’s platform approach allows manufacturers to implement digital transformation incrementally, measuring benefits at each stage while working towards comprehensive integration. The partnership with Mills CNC illustrates how technology providers and equipment manufacturers can collaborate to achieve measurable business outcomes that justify digital investment through quantifiable improvements in productivity and profitability.

Concrete business metrics will measure success in this digital transformation: quicker quote turnaround, higher win rates, reduced programming time, improved production efficiency, and enhanced workforce productivity. Manufacturers achieving these measurable improvements—through solutions like those demonstrated at the Mills CNC Technology Campus—will define the competitive landscape for the next decade of industrial production. Meanwhile, those failing to adapt risk losing business to more digitally capable competitors as customer requirements continue to evolve towards integrated digital workflows.