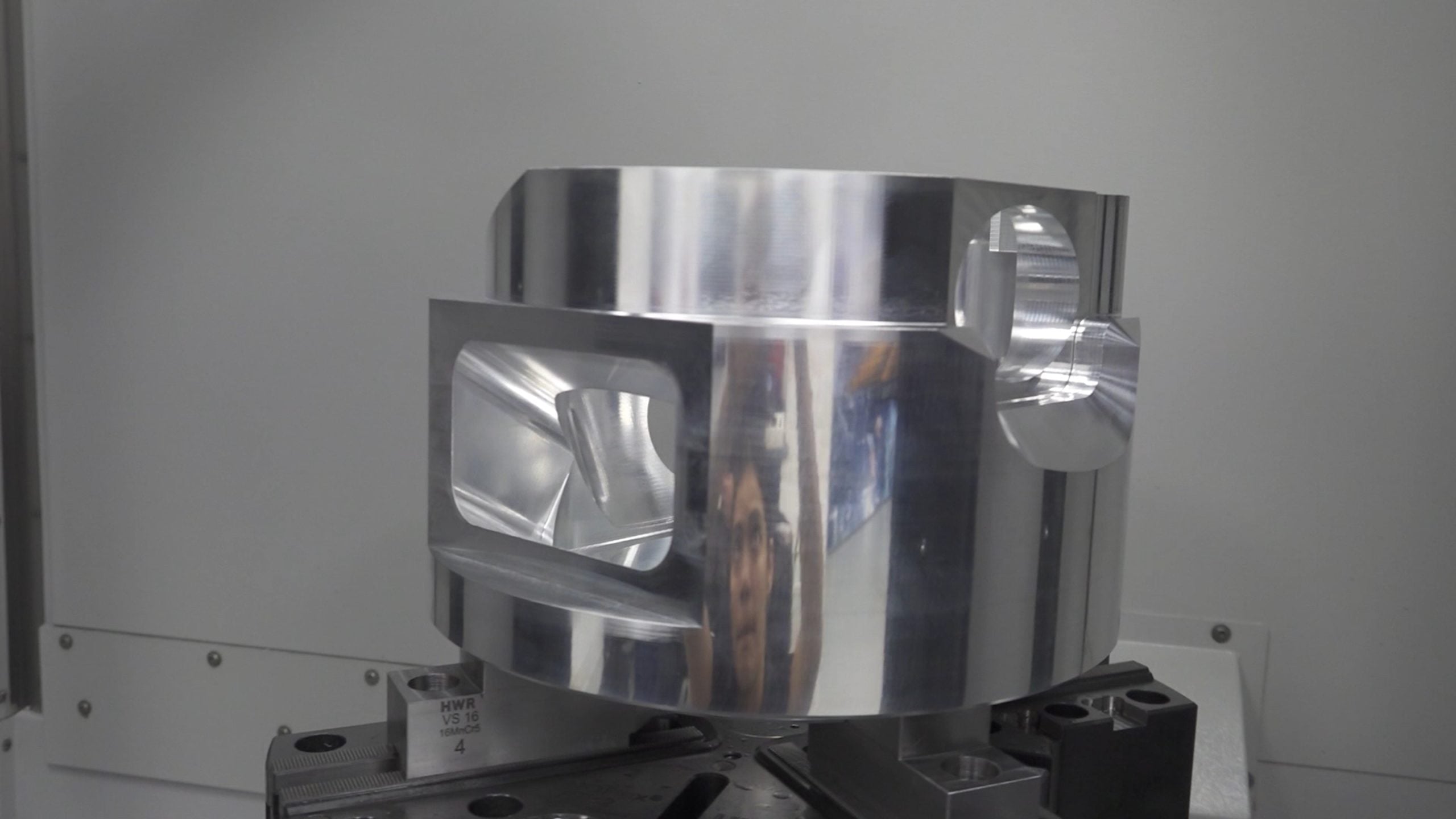

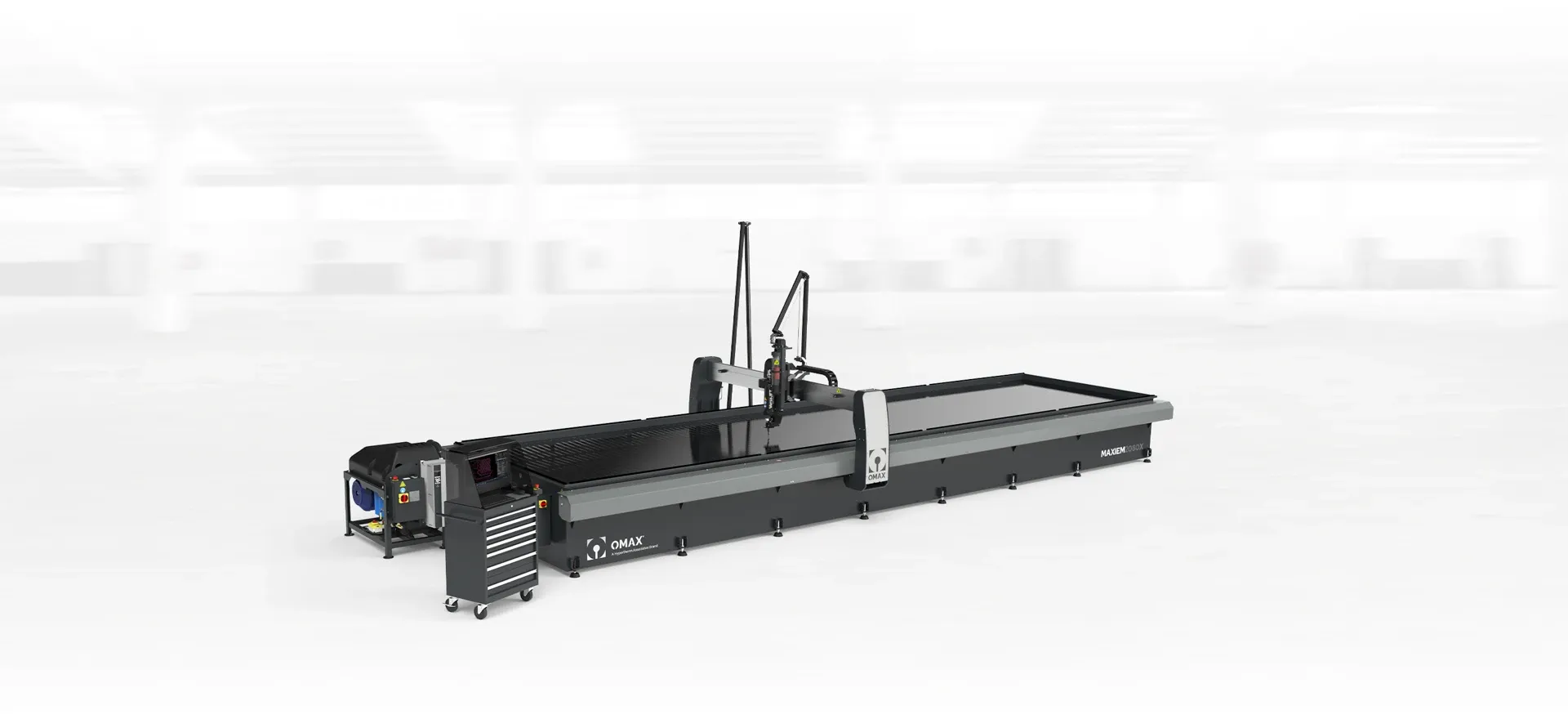

Hone-All's long association with the aerospace industry includes honing, drilling and boring services for bespoke parts, from landing gear for military aircraft to pistons for helicopter rotors . Along the way, we've invested in our people, systems and equipment to ensure accuracy, traceability and repeatability guaranteeing the stringent quality requirements required by this safety critical industry. Our continuing approval to AS9100D is testament to our commitment and success in meeting and exceeding the highest of standards. Uses Of Gundrilling In The Aerospace Industry Gundrilling, or deep hole drilling, is the process of drilling holes of precisely the required depth, diameter and position. The method has been perfected over decades, and can produce highly flexible, accurate, and reliable results. There are many applications for gundrilling within the aerospace industry, a sector which demands accurate, high quality work. Landing gear parts, for instance, often require deep hole drilling to a high standard. Components tend to be high value, necessitating accuracy to minimise errors and waste. Gundrilling is suitable for a number of materials, including steel, aluminium, titanium, and alloys, many of which are used in the manufacture of aircraft components. There may be a requirement for holes with custom features, such as threading or grooves. Accurate gundrilling can also increase streamlining and reduce the weight of engine parts, helping to create a more efficient aircraft. Find Out More At Hone-All, we have a wide range of gundrilling machines and a vast selection of tooling, allowing us to offer fast, accurate, and cost effective solutions to our customers' needs, including UTC and BAE systems. We can provide a complete project management and supply chain handling service, minimising customer spend and delivering a quicker, smoother experience from start to finish. Utilising our in-house technology and drilling equipment cuts down on transport costs for parts and materials and minimises delays by not relying on third party suppliers. For more information about the services Hone-All can offer your company, and our experience within the aerospace industry, please contact us.