Roders is the model machine for railway manufacturer

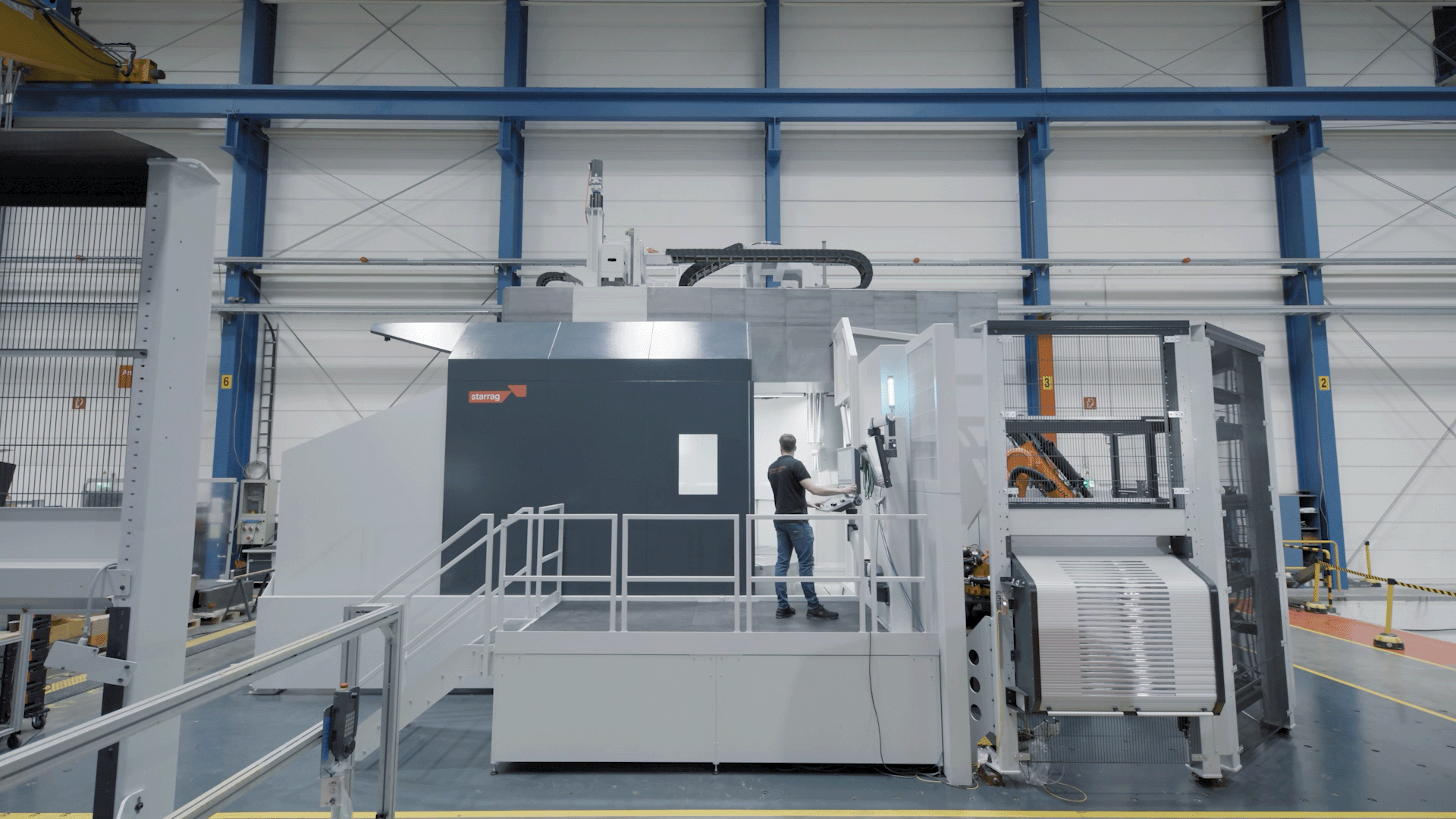

Located in Seaton, Peco is a manufacturer of model railways that started trading in 1946. The company now supplies its products around the world. The Devon company has invested in a Roders RXP 500 machining centre from Hurco Europe, so MTDCNC visited to find out more. Tristan Wakeley from Peco tells MTD: “The mainstay of the machine will be to make inserts and finish details for the tooling. It will essentially provide the finishing touches to our tools.”

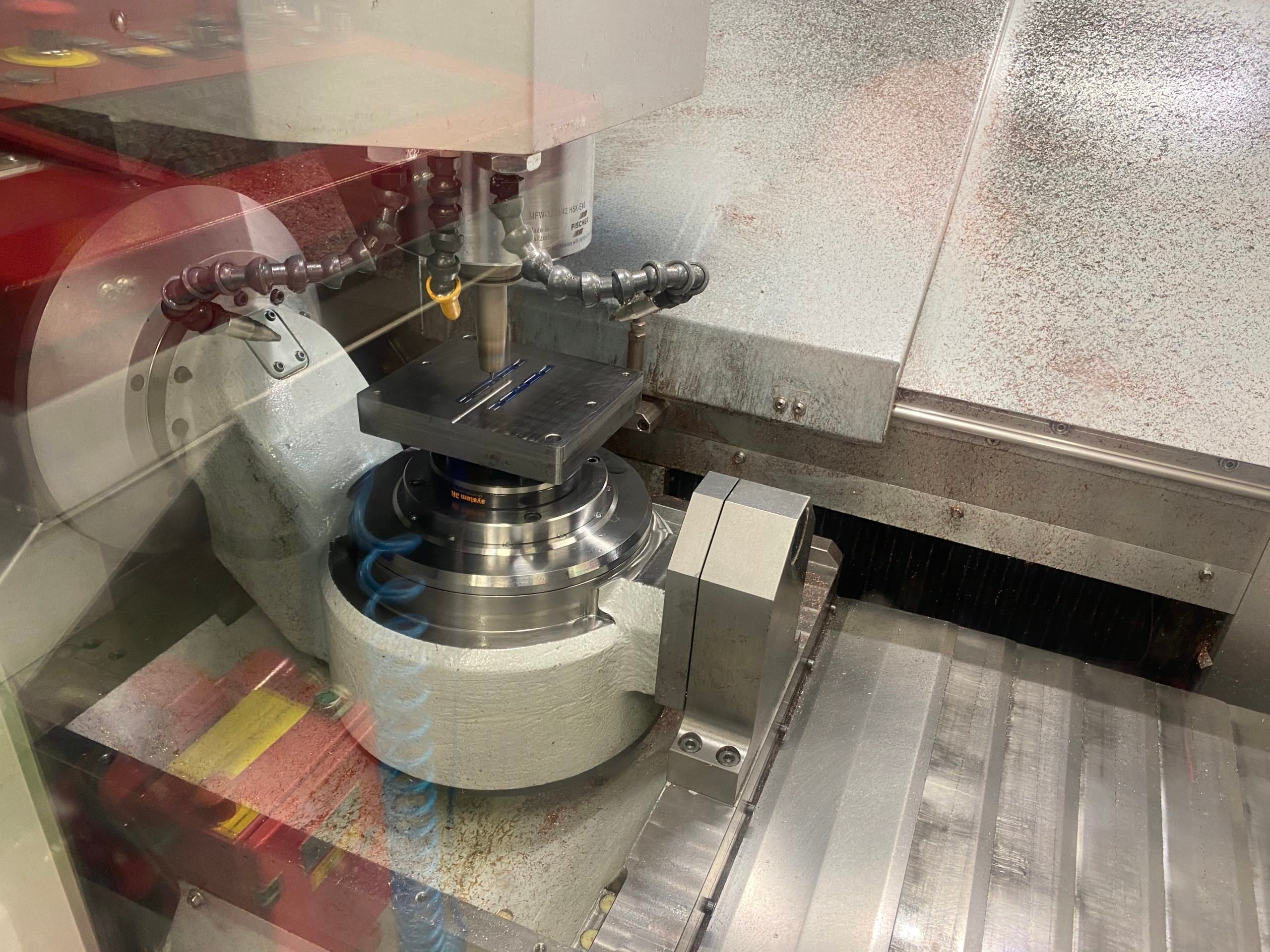

When asked how the 5-axis Roders RXP 500 machine will provide the level of quality required, Tristan confirms: “We use a carbide tool to machine at very high spindle speeds and high feed rates. The machine is not fixed to the floor, it is only located on floor pads and the machine can vibrate and move. Roders have done tests and proven you can get better accuracy than having the machine fixed.” With a machine capable of running at 42,000rpm, Peco increases its spindle speeds depending upon the diameter of the cutting tools applied. “We use tools down to 0.2mm diameter – it’s like two pieces of A4 paper pressed together. We will generally use a very small depth of cut and waveform machining. This means the tool is just doing a very small step over each time. It allows tools to move a lot faster and with such small diameters, the tools do not like slotting as they could potentially break. We use a company called Rainford Precision to supply our cutting tools.”

When asked if the cutting tools last under such conditions, Tristan continues: “It does depend on what the tools are being used for. If it is roughing, the tools will wear quicker if we are trying to blast the material as quickly as possible. When it comes to finishing, the tool life is absolutely fantastic.” With regard to measuring tools. Tristan says: “At the end of each process, the tool will automatically come to the front of the carousel and it will be measured by a Blum measuring system. This checks the length of the tool to make sure you are machining in the right place. It also measures the diameter of the tool. We will set a tolerance of what we will allow for the tool to be over or under tolerance depending on how well the tool has been set. Our longest process so far has been around 36 hours of machining, this is due to spindle cooling and a thermal compensation system for cutter life. The machine has been running almost constantly since we bought it in 2019 and we have had no spindle or quality issues since we bought the machine.”

With the tool moving in Y-axis and the component moving in X-axis, the Roders machine achieves optimal rigidity and confirming this, Tristan says: “As the machine uses a touch probe system when you place a part inside, it always knows where it is. The Blum laser system always measures the tools so it knows where they are and then it’s down to the CAD/CAM software to prevent any collisions and accidents. The reason we opted for a 5-axis machine is that a 3-axis is limited by its Z step-downs and we generally work to around 5µm and we do not want the pyramid type effect on the parts when we finish the machining. With a 5-axis machine, you can obviously tilt the part over and this allows for much larger stepovers. The classic example is on a point tool where the upstands when using 3-axis machining took 17 hours and on our 5-axis Roders it took around one hour, so there are huge savings to be made. The accuracy of the machine may be a little over-the-top for what we need, but as we want to make high-quality parts for our customers – it is perfect.”