OK-VISE Multi-Rail

OK-VISE MULTI-RAIL RM System is the best-selling generic purpose system of OK-VISE. Compared to a traditional…

View productWALMAG GRINDMASTER ELECTRO-PERMANENT MAGNETIC CHUCK FOR GRINDING

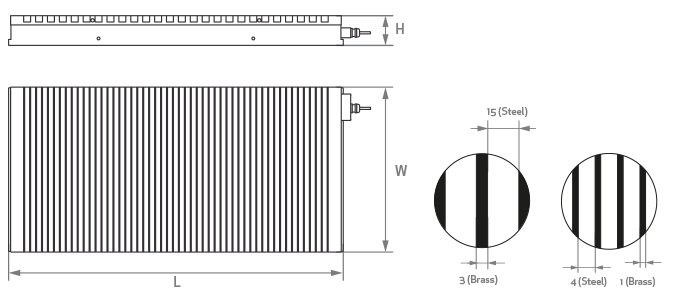

The Grindmaster series magnetic chucks are designed for grinding a very wide range of workpieces, from virtually small and thin to larger pieces. The electro-permanent technology used ensures not only high accuracy (it does not gradually heat the chuck after switching on), but also high safety and minimum operating costs.

Advantages:

The Grindmaster electro-permanent magnetic chuck is highly accurate and can hold both small and thin parts as well as larger workpieces. A short electrical pulse is sufficient to turn it on and off and thus very economical. It has a high level of safety, where workpieces are still held by means of strong permanent magnets in the event of a sudden power failure. We can offer you several pole pitch variants. The chuck has a holding force of up to 120 N/cm2 evenly distributed across the surface of the chuck.

Be first to see all the updates from MTDCNC

Our newsletters frequency varies dependant on content

All the latest deals from the industry feature on our newsletters