OK-VISE Multi-Rail

OK-VISE MULTI-RAIL RM System is the best-selling generic purpose system of OK-VISE. Compared to a traditional…

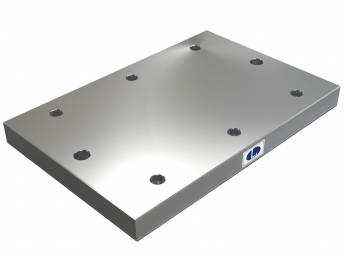

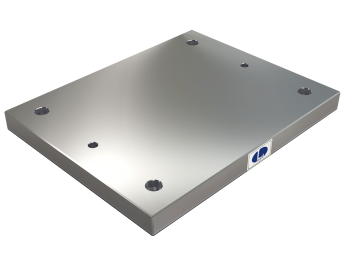

View productBase Plates

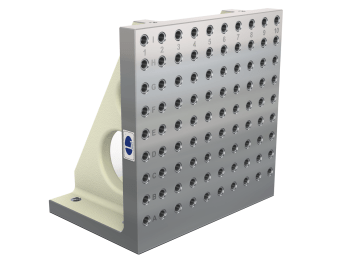

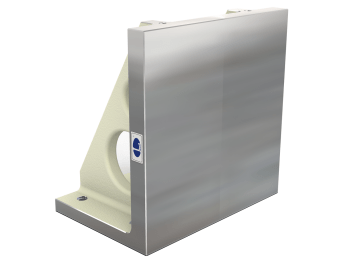

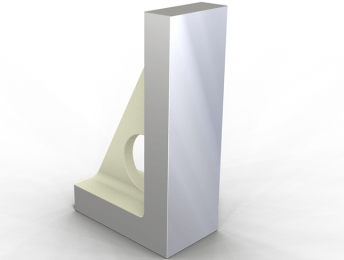

At First Machine Tool Accessories, we offer two kinds of base plates; flat base plates and angled base plates. These two types of plates can often be found and used in both vertical and horizontal heavy-duty machinery. Our base plates are also suitable for construction and or scaffolding jobs. These plates can have either t-slots or come with plain machinable faces. We would recommend you use flat based plates for any machinery and construction jobs to ensure a stable working area. Angled plates, on the other hand, are best for fastening equipment to walls and curbs.

An angle plate is a work holding device used as a fixture in metalworking, they are used to hold workpieces together during marking out operations. There are a range of angle plates available in the market, ranging from adjustable angle plates to gridded angle plates. To ensure, the high quality and durability of these milling angle plates, they are engineered made from such strong materials as cast iron. In doing so, it ensures further stability in rigidness. In many instances, angle plates have slotted, or “T” bolt slots carved into them to provide consistent security.

.

.

At Machine Tool Accessories we offer a range of CNC mill sub plates in our arsenal of equipment, ranging from gridded fixture sub plates to T-Slot base plates. However, it must be noted that sub plates can have varying names in the industry. We have included this list here for ease of reference. Subplates can be known as mounting pads, subbases, and base plates. In terms of benefits of using sub plates, these can include a means to connection for valves, minimising leakages to dramatically simplifying work holding setups.