Tebis CAD/CAM/MES Experts Demonstrate Digital Twin and CAM Automation Capabilities at EMO’2019

Tebis, a specialist for CAD/CAM/MES and associated services for mechanical component, model, pattern, die and mould manufacturing, presented the latest developments and applications of Digital Twin and CAM Automation with CNC Process Standardisation at EMO in Hannover this year.

With the combination of software, services and consulting, Tebis presented itself as a holistic solution provider. The highly automated CAD/CAM/MES system is being continuously renewed and developed for the growing needs of customers.

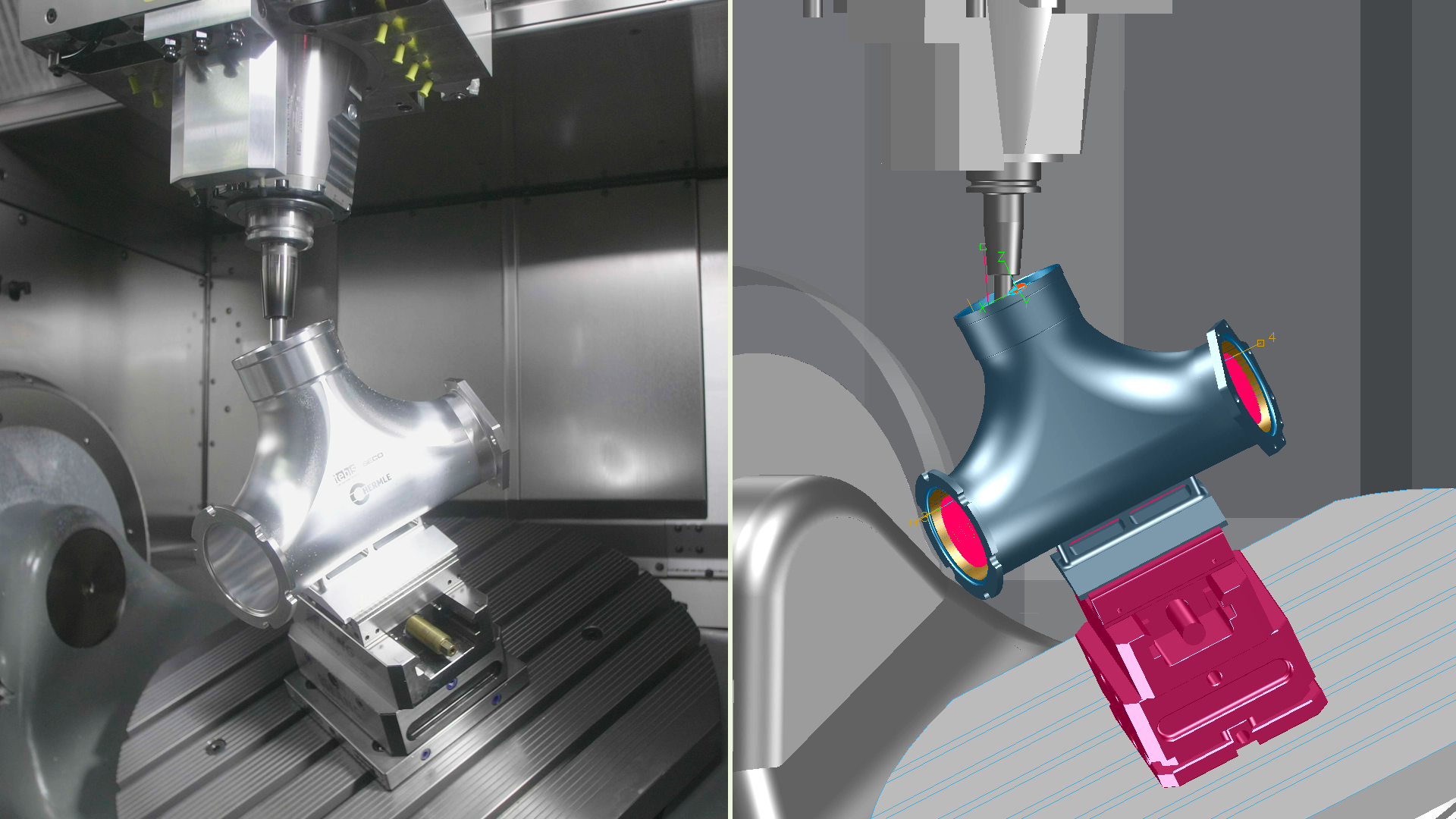

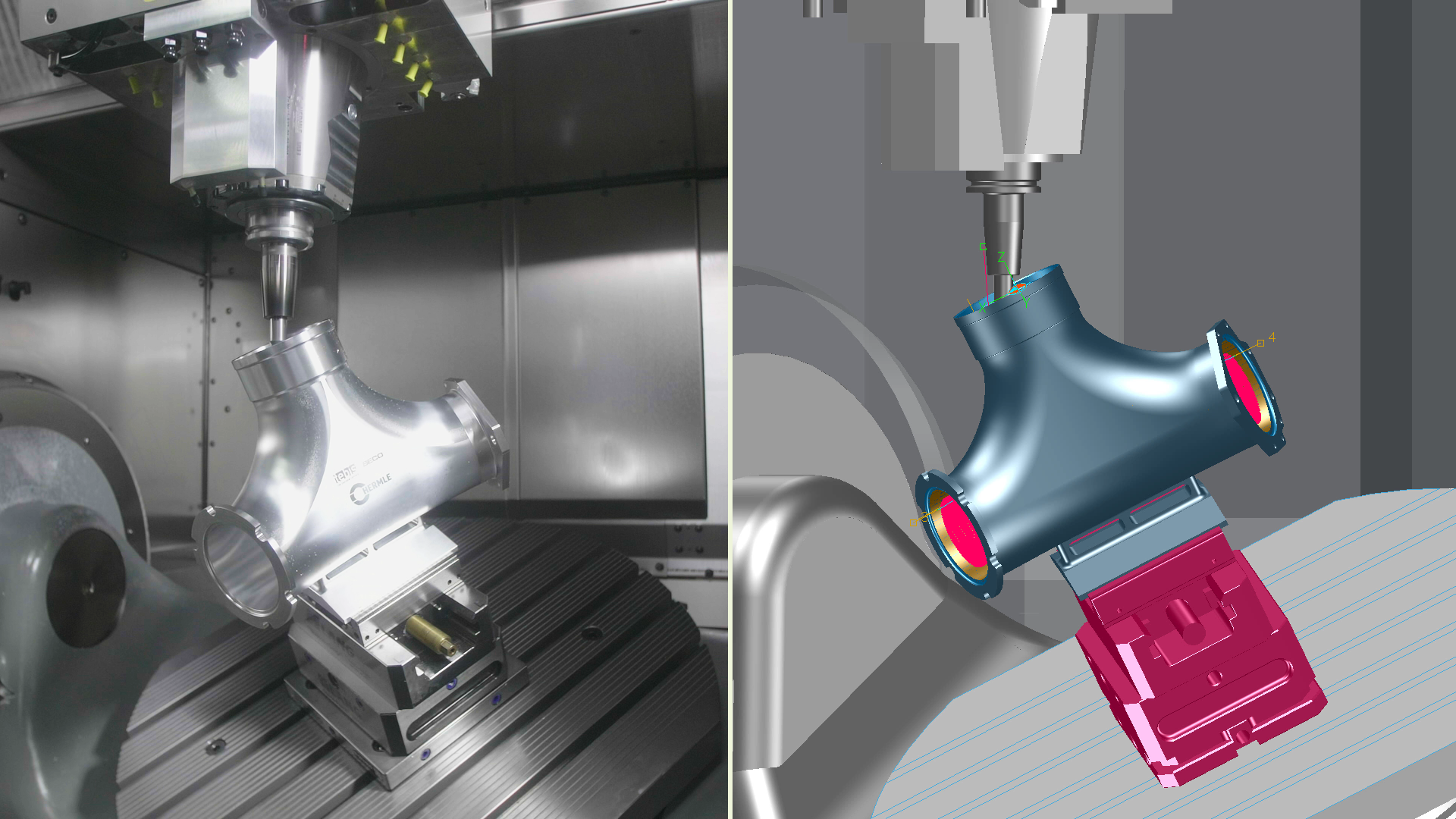

CNC Machining Safety and Efficiency with Digital Twin Technology

Customers’ machines, tools and clamping devices are sophisticated and expensive. Fully utilising them and avoiding collisions and damages are critical for workshop operations. Tebis has been developing and offering the capabilities to allow customers to build Digital Twin models of these into Tebis CAM software. With Digital Twin models, Tebis completely simulates and checks NC programs against collisions to ensure the highest level of CNC machining safety. Different from other CAM packages, Tebis Digital Twin models are complete mirrors of the physical machines, tools and clamping devices, including multiple machine heads, machine kinematics, tool change movements, toolpath links, machine control macros, etc. With all these simulated and checked in the virtual world, workshop managers and machine tool operators can have the confidence to run the machining operations unattended, possibly overnight.

In addition, Tebis’ MES solution ProLeiS provides customers with production planning and control tools. Machine and operation data on the shop floor can be acquired in real time and used for production planning and control. Managers can have a detailed overview of all manufacturing projects and operation status of all machines. With Tebis ProLeiS solution, customers can ensure delivery to their customers on time and cut costs.

CAM Automation with Process Standardisation

Achieving consistent quality while ensuring CNC machining safety and efficiency is important to all customers. With CAM Automation and CNC Process Standardisation, Tebis replaces traditional, repetitive manual programming steps by automatically accessing stored manufacturing data: The software evaluates the digital CAD part model and accesses structured images of the company’s existing manufacturing environment and standardised manufacturing process data to calculate NC programs.

Tebis manufacturing data libraries include machine tools, cutting tools, machining parameters, machining features and machining process templates. All the information can be stored and managed across companywide computer network and possibly on the cloud. This allows the best machining practices to be shared among CAM/CNC engineers. This is hugely beneficial to customers as this is very easy to use, and it reduces training time and relieve skills shortness.