Ease of use for CAM models and powerful CAD functions

OPEN MIND has now introduced the 2025 release of its hyperMILL® CAD/CAM suite. The highlight of the new…

HAIMER and OPEN MIND together demonstrate how to perform complex milling operations with vigor and dynamism.

HAIMER supports the DEL Augsburger Panther ice hockey team as a premium partner. In this context, the supplier of complete systems in the field of machine tools demonstrated the performance of its tools and tool holders by machining a model of a panther. The OPEN MIND CAM specialists performed the sophisticated programming with their hyperMILL ® software .

In Germany, the “Augsburger Panther” playing in the DEL (“Deutsche Eishockey Liga”, ie the German ice hockey league) are among the most famous panther species. Based in Igenhausen, just 30 minutes from Augsburg, the company Haimer GmbH is both a supporter and partner of the professional ice hockey team. The family business, which is a leader in the development, manufacture and sale of high precision products for metalworking, had the idea to proceed with the machining of an aluminum panther in the center of ‘HAIMER app. This exhibit demonstrates that 5-axis milling with tool holders and solid carbide burs from HAIMER is second to ice hockey when it comes to speed, vigor and dynamism.

Konstantin Brodowski, director of the application center, draws other parallels: “In ice hockey it is not just about speed and hardness, each player must have excellent technique and apply it within the framework. of perfect interaction. This also applies to us, when high-tech products from HAIMER are combined with the most modern machine tools and high-end CAD / CAM software. “

One-to-two between machining professionals and programming professionals

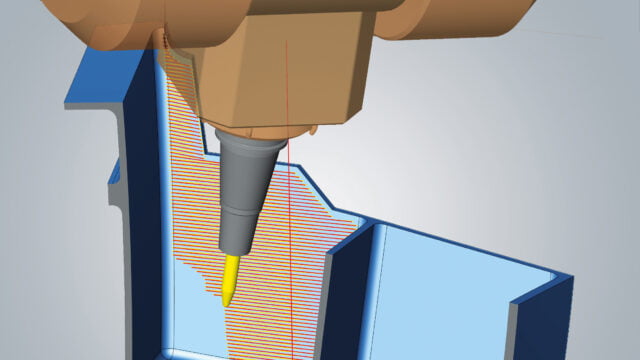

In search of “teammates” to carry out the panther project, the HAIMER company turned to the CAD / CAM editor OPEN MIND from Wessling, who has been its partner for several years. In the field of machining, its hyper MILL ® CAM system is considered one of the best for 5-axis machining and is therefore ideally suited for programming completely free-form contours. OPEN MIND immediately agreed to mobilize an application technician to program the unusual exhibit and participate in the common milling operation. Christian Neuner, Head of Global Engineering Services, explains: “A scale model of this type is an excellent opportunity to demonstrate the versatility and flexibility of our software. We ourselves also present analogies with the panther. Indeed, hyper MILL ® has many functions allowing the CAM user to push the limits of the machine with vigor in order to quickly reach its objective. “

Jakob Nordmann, Application Engineer at OPEN MIND, therefore traveled to Igenhausen for a few weeks to implement perfect programming and machining with Daniel Swoboda, application technician at HAIMER. As a milling machine, they opted for the DMG MORI HSC70 linear 5-axis machining center, available in the HAIMER application center. Thanks to its speed and precision, it offers the best conditions for machining aluminum and obtaining high surface qualities.

Tooling solutions that meet all challenges

The machining of the panther’s head was particularly delicate, in particular that of the mouth with the canines, the representation of which is very detailed. Due to its long and thin shape which makes it extremely sensitive to vibrations, the shank was also difficult to machine. In addition, many areas were very difficult to access. This is why the people in charge decided to machine the part in two settings, for which a 5-axis LANG Makro Grip vice was used as a jig.

The reduced accessibility also had an influence on the choice of tools. While application specialists used the shortest tools possible, they had to resort to tools measuring up to 278mm in length for some parts. Daniel Swoboda therefore opted for HAIMER Duo-Lock ™ modular tools to perform roughing operations. The system consists of carbide tool heads which are connected to various extensions via an extremely stable interface. Concretely, he chose a version with four teeth with edge radius of the Duo-Lock ™ HAIMER MILL Alu series. These tools are precisely balanced and are characterized by very high repeatability of the lengths. They offer a level of precision positioned ideally between aggressiveness and defense. “We clamped the cylindrical extensions coated with the Duo-Lock tools in the HAIMER Power shrinking tool holders,” explains Daniel Swoboda. “This results in significantly stronger clamping and lower vibrations than with standard tool holders. This allows for larger passes and a higher chip removal rate. “

For the finish, the choice fell on the solid carbide milling cutter of the HAIMER MILL Alu series in hemispherical version, whose micro geometry is specially designed for a smooth feed and high surface quality. With the clamping in the extremely thin, yet anti-vibration, HAIMER Power Mini Shrink tool holders, those in charge took the limited space into account.

Jakob Nordmann, a colleague from OPEN MIND, adds: “The fact that all HAIMER tool holders and tools are also available as DXF and STEP files has been very helpful for my work. The models can simply be downloaded from the HAIMER homepage. These are integrated in three clicks into the database via our hyper MILL ® TOOL Builder module and are available for programming and simulation. “

Practical: CAD for CAM and simulation

Optimal programming performance was required to achieve a good visual appearance. First crucial point: the panther was delivered as an STL data model. Jakob Nordmann, hyper MILL ® specialist , explains: “As a conversion to a surface model would have been very expensive, we decided to perform the milling on an STL mesh but to use a line-to-line procedure with a spacing of 1 mm so that the structure of the facets remains invisible.

For very detailed parts like the mouth, tail or folds at the joints, we have generated additional surfaces that can be combined with the STL network in hyper MILL ® . For this, J. Nordmann used hyper CAD ® -S, the “CAD for CAM” system specially developed by OPEN MIND to meet the needs of programmers.

As different tool inclinations were required due to the limited space, he had to be careful to observe the exact spacing between the lines and ensure a smooth transition with no visible seams. “To do this, I used the” Edit tool path “function”, reveals J. Nordmann. “It allows you to first define the entire tool path and then divide it into several zones, which are then machined with different inclinations using several tools. I thus saved a lot of work. “

Another essential element for milling the panther: hyper MILL ® VIRTUAL Machining Center, a reliable NC simulation solution that ensures conformity of virtual machine movements with reality and guarantees reliable collision detection.

It took almost three weeks of intensive teamwork to complete the first panther. The curious will be able to admire a model of it at HAIMER or OPEN MIND during the fairs to come. Of course, the Augsburger Panther club also received a copy to display in the stadium entrance hall or in the changing room corridor in order to motivate the players when entering the ice.

Be first to see all the updates from MTDCNC

Our newsletters frequency varies dependant on content

All the latest deals from the industry feature on our newsletters