From Brazil to the US – this booth is buzzing for a reason!

Thirty years of experience, thousands of machines on the market, and a booth buzzing with energy…

For a company that traditionally relies on manual labor, achieving these goals is a real challenge, even more so in a difficult job market and an activity that experiences significant seasonal peaks. Almost half of DCL’s customers experience significant peaks in demand during the holiday season and achieve up to 40% of their sales in the last two months of the year.

A difficult quest..

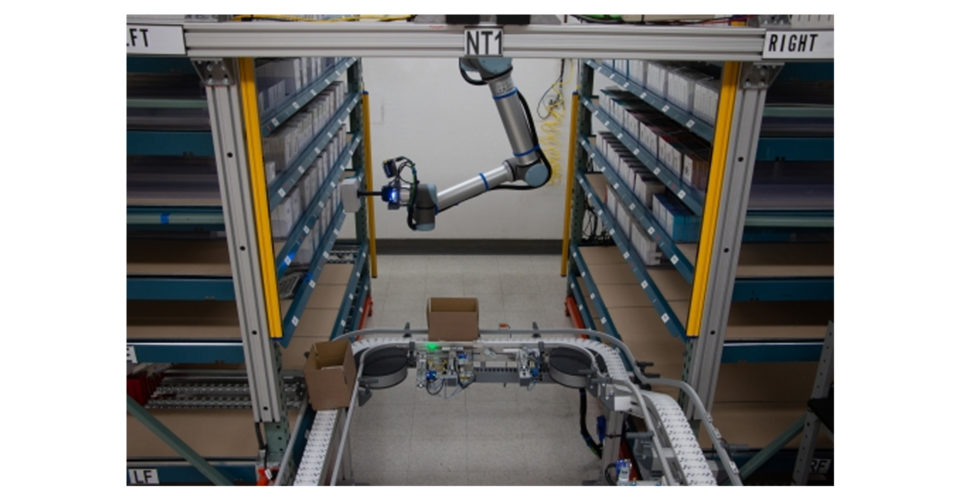

The DCL team was looking for robotic order picking and pick & place systems, without success. They came up against price constraints, too long return on investment or quite simply a lack of flexibility of the available solutions. “So we were like, ‘Why not try to build this robotic application ourselves? Says Brian Tu, Chier Revenue Officer of DCL Logistics. DLC Logistics planned to install the robot in the center of two cells to collect the products indifferently in one and the other. With a reach of over 1300mm, Universal Robots’ cobot UR10 stood out: “Universal Robots provided a solution that met our needs,” says Brian Tu. “In addition, its modularity has enabled us to develop it little by little”.

An application made to operate 24 hours a day, 7 days a week

The app includes a conveyor that collects the boxes, aligns them and puts them in the loading position. The robot takes a product every six seconds and takes it to a scanner, then puts the product in the box. If the item is incorrect, the robot places it in a reject bin and continues to pick up the next item without interrupting production. The app is designed to be able to run 24/7, without any human interaction. The automated line has been of great help to the operators, relieving them of a great burden, as the company accumulates orders, even overnight. A valuable asset for seasonal peak periods in the United States, such as Black Friday or the day after Thanksgiving. That day, the UR robot collected up to 4,400 orders in one day.

500% increase in productivity and 50% savings in labor costs

In the past, it took five people to manage a traditional manual picking process: one person in the warehouse to prepare the order, another to bring it to the line, a third to check it, a fourth to equip it. and one last to pack and ship it. “The robotic system can do in two hours what a team of five people would do in a full day and saves us over 50% in labor costs,” says Brian Tu. Employees are not replaced by the cobot: they are reassigned to other departments or trained in the management and maintenance of the robot. During peak seasons, the robot allows the business to meet customer needs without the need for additional staff.

3 month return on investment, 100% increase in accuracy

The savings made allow DCL Logistics to deliver orders faster and with less effort, and therefore lower their prices for the company’s customers.

The DCL Logistics automation team was also pleasantly surprised by the ease of use of the robot’s interface and software. The flexibility of the system implementation and the quality of support provided by Universal Robots were also highly appreciated.

Walter Perchinumio, Senior Software Engineer at DCL Logistics, says: “As soon as someone came up with the idea of using a robot for order fulfillment, I was very excited. We went to the Universal Robots Academy site to learn what this six-axis robot was capable of ”. In particular, he was delighted to find the free application simulator on the Universal Robots website. This tool gave him full confidence in the team’s ability to program the system successfully: “The first month we worked with the robot was exclusively devoted to simulating its use”.

The UR + platform, source of certified applications

The DCL Logistics automation team used the UR + online platform as well as the simulator to find and choose the right devices for the application. The tested and proven certification of each UR + product as well as the UR CAPS software make this process a “plug-and-play” scenario instead of having to relearn robot controls. With the UR cobot, “The task was actually very easy,” says Walter Perchinumio.

Plans for the future: a system with eventually 20 UR cobots

Dave Tu, President of DCL Logistics, has big ambitions in the e-commerce sector, even though it currently represents only around 15% of the retail market: “We imagine that over the next five to ten years, robotics as part of DCL’s activities will be even more important. We want to integrate more systems to reach up to 20 robots within 10 years ”.

Be first to see all the updates from MTDCNC

Our newsletters frequency varies dependant on content

All the latest deals from the industry feature on our newsletters