Recognizing downtime changed everything for this machine shop!

At Coastal Machine & Supply, the team has embraced the future of manufacturing—where guesswork is out,…

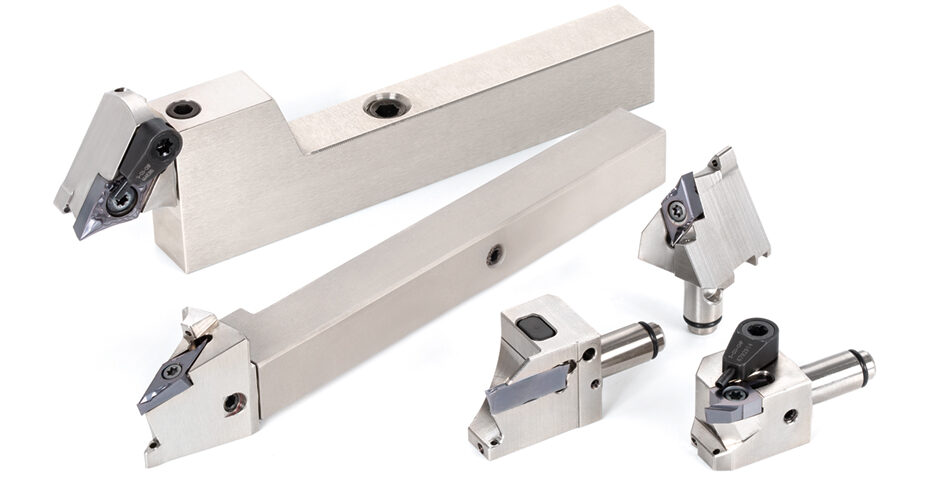

At PMTS 2025, Tungaloy-NTK America introduced its ModuMini-Turn Series, a modular tooling solution specifically designed for Swiss-type CNC lathes. This innovative system is engineered to minimize machine downtime by allowing users to replace tool heads quickly and easily without removing the shank. By eliminating the need for tool position resets, the system offers significant time and cost savings, helping manufacturers streamline their production processes and maintain continuous operations.

The ModuMini-Turn Series features several key benefits, including high precision and repeatability. It achieves a repeatability rate of ±5 microns, ensuring consistent, high-quality results even for complex machining tasks. This precision is crucial for industries requiring high tolerance parts. Additionally, the system’s compact and rigid design enhances machining stability, which reduces vibration during cutting. This results in improved surface finishes and extended tool life, reducing the frequency of tool changes and further contributing to efficiency.

One of the standout features of the ModuMini-Turn Series is its versatile tool head options. It supports a wide range of applications, including external turning, grooving, threading, and cut-off operations, making it a highly adaptable solution for diverse machining needs. Furthermore, the modular design of the system provides cost efficiency, as users can replace the tool heads rather than the entire tool assembly, resulting in reduced tooling costs over time.

Designed to streamline operations and improve productivity, the ModuMini-Turn Series from Tungaloy ensures reliable and repeatable results for high-precision machining tasks. By reducing downtime and enabling faster tool changes, this solution not only enhances machining efficiency but also lowers operational costs, making it a valuable tool for manufacturers looking to optimize their production processes.

Stay up to date with the latest industry news and events.

Be first to see all the updates from MTDCNC

Our newsletters frequency varies dependant on content

All the latest deals from the industry feature on our newsletters