JJ Hardy & Sons Celebrates the Retirement of Long-Serving Team Member Archie

JJ Hardy & Sons, a renowned family-owned precision engineering firm established in 1856, announces the upcoming…

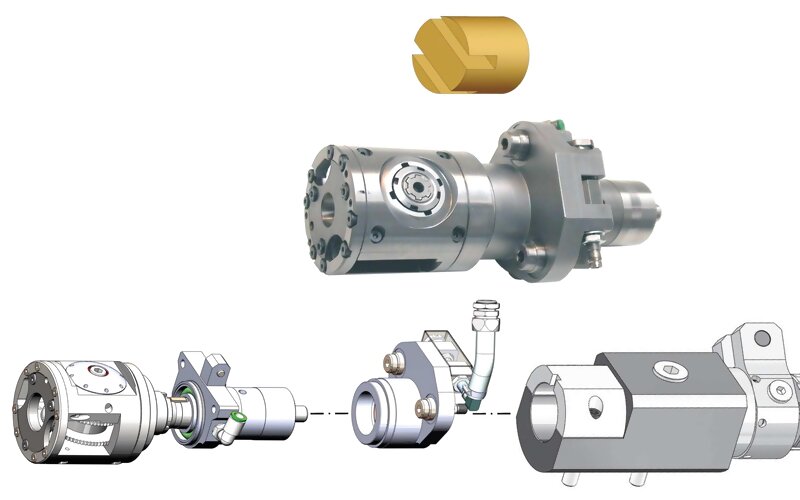

At PMTS 2025, SPC Innovations Inc. showcases its latest advancements in multispindle attachments, designed to significantly enhance productivity, reduce secondary operations, and facilitate quick job changeovers. Highlighted in their display is Autor Engineering’s updated line of multispindle attachments, including the synchronous frontal milling (slotting) attachment, which is equipped with a safety torque switch.

These synchronous attachments and CNC-controlled slides can be added to traditional cam machines, allowing manufacturers to perform complex operations that were typically done through secondary processes. Operations like frontal milling, cross drilling, off-center drilling, thread-chasing, milling of threads or flats, marking on flats, and eccentric turning are now possible directly on the multispindle machine, eliminating the need for secondary operations.

The attachments are powered by the machine’s synchronous tool drive (pick-up spindle drive), a feature already available on most multispindle machines. These enhancements allow complex operations to be seamlessly integrated into the primary machine without affecting spindle speeds or cycle times. This not only reduces setup times but also ensures that parts are produced complete on the first pass, enhancing overall efficiency.

In addition to its multispindle milling advancements, SPC Innovations also presents a live demonstration of its In-Process Part and Tool Verification System. This economical and modular system can be used across all types of production machines on the shop floor, providing real-time verification of both parts and tools, further boosting production reliability and minimizing downtime.

By integrating these advanced features, SPC Innovations is helping manufacturers streamline operations, reduce costs, and improve overall throughput, making their solutions ideal for high-volume production environments.

Stay up to date with the latest industry news and events.

Be first to see all the updates from MTDCNC

Our newsletters frequency varies dependant on content

All the latest deals from the industry feature on our newsletters