Mastercam 2026 Launches with AI-Driven Tools and Enhanced Machining Capabilities!

Mastercam has unveiled Mastercam 2026, an advanced release packed with productivity-boosting tools, AI-powered CAM intelligence, and…

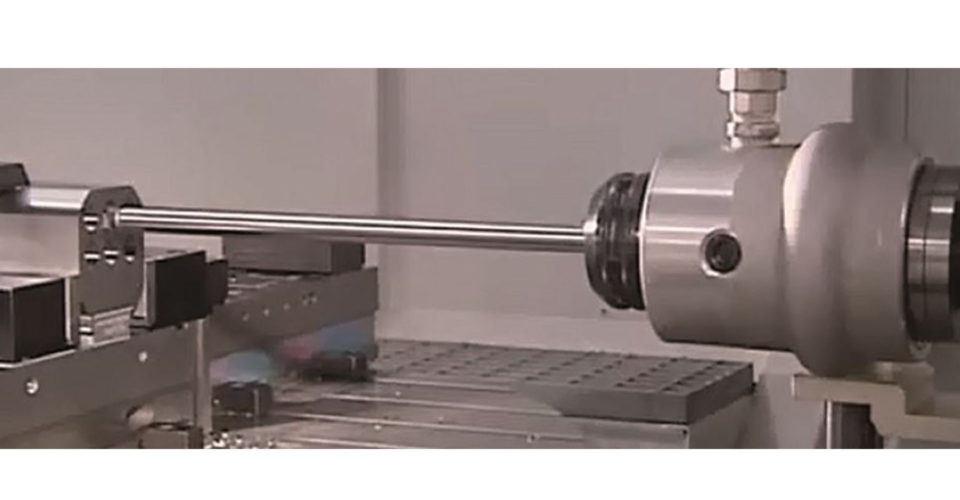

SOMEX now offers custom made deep hole drilling units capable of drilling up to 12mm diamters and as deep as 100x the diameter. These modules can be integrated directly into transfer machines, special purpose machines, or conventional machines such turning machines.

In addition to standard MAX machining units, SOMEX can now offer periphirel components.

SOMEX uses single cutting edge and carbide spiral drills up to 70x the diameter. The SOMEX design concept combines the guide bushing with a chip basket, allowing both items to travel in unison. The movement of the guide bushing is air-driven, which helps to provide a much closer contact to the part while preventing the escape of the coolant medium. For longer deep hole drilling applications, it may be necessary to integrate a support bushing to stabilize the deep hole drilling tool.

The degree of accuracy in a deep hole drilling application measured in the deviation from the theoretical part center line is greatly enhanced by a slow part rotation in a counter-clockwise direction.

For deep hole drilling applications above 18mm diameters, the MAX machining units can be equipped with drilling systems from BTA- or EJEKTOR lines. In these applications, the coolant and chip management is accomplished through the spindle center. The emulsion is collected at the backend of the spindle, filtered and pressurized to re-enter the coolant system.

Be first to see all the updates from MTDCNC

Our newsletters frequency varies dependant on content

All the latest deals from the industry feature on our newsletters