MC Machinery Names Mitch Foley as Finishing Product Manager!

MC Machinery Systems Inc., a leading provider of advanced machinery solutions, has announced the appointment of…

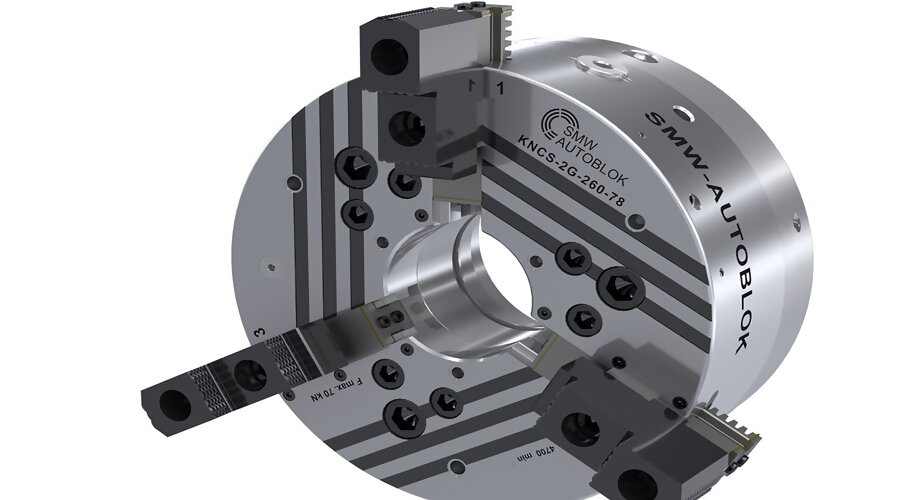

SMW Autoblok Group has unveiled the TMS-2G quick-change system, designed to enhance efficiency and precision in CNC turning operations. This advanced system enables rapid spindle changes, allowing operators to switch chucks in under one minute, significantly reducing downtime and streamlining production workflows.

The TMS-2G system is highly versatile, compatible with a variety of clamping devices such as chucks, mandrels, and collet chucks, whether they use automatic or manual clamping systems. This adaptability makes the TMS-2G suitable for a wide range of metalworking applications, providing flexibility for operations that frequently require different workholding solutions.

A standout feature of the TMS-2G system is its precision and repeatability. The internal slide mechanism and quick plate locking system ensure changeover accuracy within 7 μm, delivering the consistency needed for high-quality machining. This precision helps manufacturers maintain strict tolerances while simplifying the process of switching workholding devices.

The system also includes built-in contaminant protection, ensuring reliable performance even in challenging machining environments. This added durability helps maintain the system’s integrity and ensures consistent accuracy, making it an ideal choice for precision-focused industries.

By combining speed, versatility, and accuracy, the TMS-2G quick-change system addresses the demands of modern manufacturing, helping operators improve productivity while maintaining high-quality standards. SMW Autoblok’s innovative solution reflects its ongoing commitment to providing efficient and reliable workholding technologies for the manufacturing sector.

Stay up to date with the latest industry news and events.

Be first to see all the updates from MTDCNC

Our newsletters frequency varies dependant on content

All the latest deals from the industry feature on our newsletters