Revolutionizing Semiconductor Testing: TANAKA Introduces TK-FS Probe Pin Material

TANAKA Kikinzoku Kogyo unveils TK-FS, a groundbreaking alloy designed for probe pins in semiconductor test equipment. With high hardness, low specific resistance, and exceptional pliability, this material redefines industry standards, promising enhanced performance across various probe pin types.

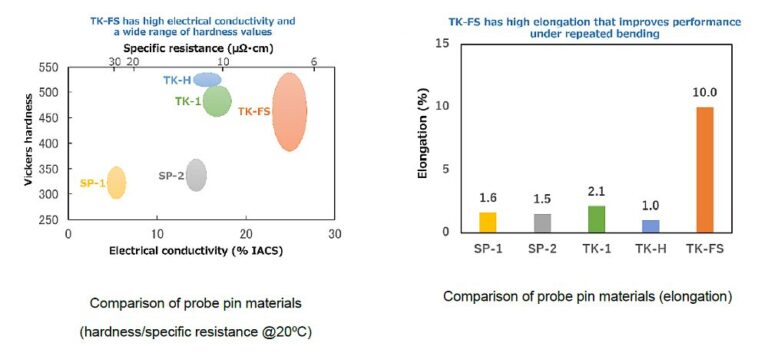

Previously focused on palladium (Pd) materials for pogo pin-type probe pins, TANAKA expands its portfolio with TK-FS, catering to cantilever-type or vertical-type pins for wafer testing. With a Vickers hardness of at least 500, specific resistance of at most 7.0µΩ・cm, and durability for over 10 bends, TK-FS outperforms existing materials, offering unparalleled versatility.

Semiconductor testing demands utmost reliability to assess product performance accurately. With the rise of IoT and increasing semiconductor usage in various sectors, the demand for reliable testing equipment is on the rise. TK-FS addresses this need, promising extended service life and reduced costs for semiconductor test equipment.

The goal for TK-FS is ambitious: to double shipment volume by 2028 and transition most existing probe pin materials to TK-FS in the future. TANAKA Kikinzoku Kogyo aims to drive innovation in the semiconductor market, anticipating significant growth in the coming years.

Key Features of TK-FS:

- Simultaneously achieves high hardness, low specific resistance, and exceptional durability

- Offers a wide range of Vickers hardness values (400 to 520) through unique processing technology

- Boasts higher elongation (8% to 13%) compared to existing probe pin materials from TANAKA Kikinzoku Kogyo.

Original source from www.asiamanufacturingnewstoday.com