Revolutionizing CNC Controls: The Future of Automation in Manufacturing

The realm of automation in manufacturing is rapidly evolving beyond the mere movement of parts. A paradigm shift is occurring as manufacturers embrace dynamic programming, a groundbreaking advancement enabling machines to automate tasks once deemed too complex for conventional computing.

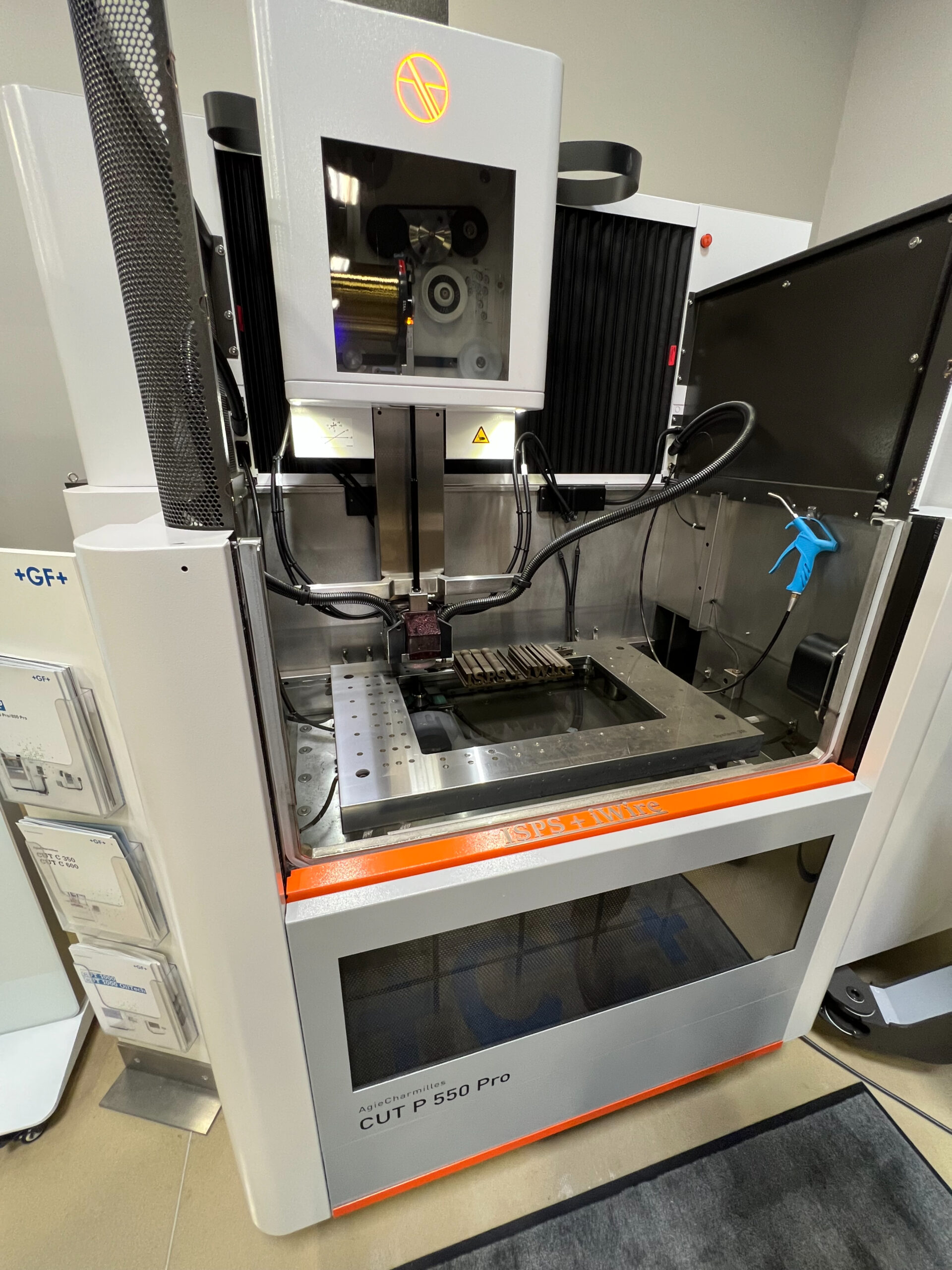

GF Machining is spearheading this revolution with its innovative EDM controls, ushering in a new era of efficiency and adaptability. By incorporating dynamic programming into their controls, GF Machining empowers users to effortlessly save and generate toolpaths, revolutionizing the way CNC machines operate.

Traditionally, GF Machining has offered two types of EDM controls: a conventional G-code CNC and an integrated CAM system with a human-machine interface (HMI) for real-time adjustments. While the G-code control appeals to users seeking simplicity, the CAM system with dynamic programming capabilities enables unparalleled adaptability to changing parameters.

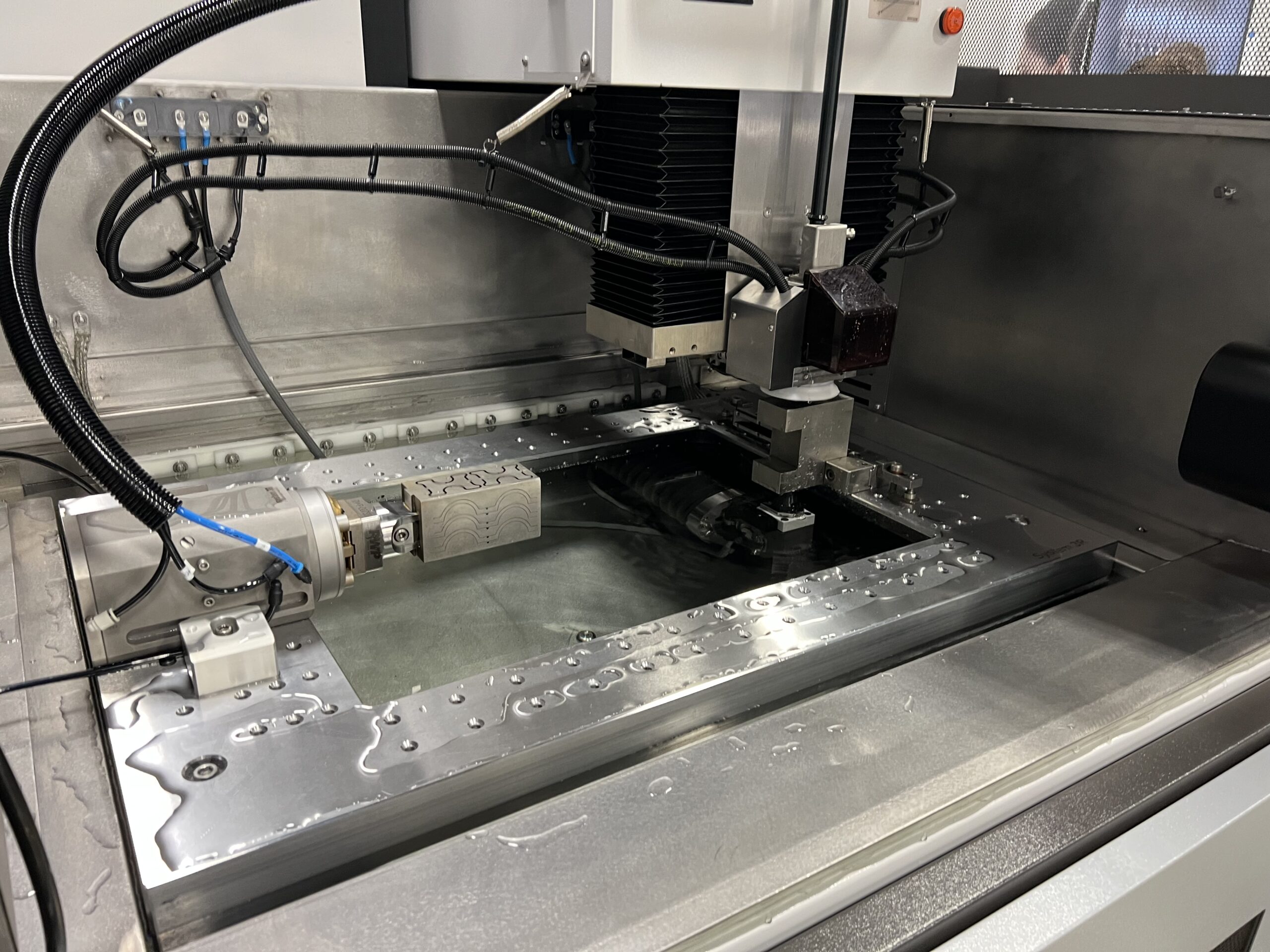

Dynamic programming allows the control to autonomously adjust priorities and generate G-code tailored to each job’s requirements, providing users with flexibility and efficiency. With this feature, operators can swiftly modify toolpaths and adapt to evolving circumstances, enhancing productivity and precision.

To bridge the gap between traditional G-code controls and dynamic programming, GF Machining introduces the Uniqua control—a fusion of both systems in a single interface. Uniqua offers users the flexibility to seamlessly transition between G-code CNC and the CAM-integrated control, combining the simplicity of traditional programming with the adaptability of dynamic programming.

Dynamic programming revolutionizes unattended EDM operations, exemplified by the Early/Late capability. This feature enables the control to autonomously reorganize programs to maximize productivity during unattended machining, significantly reducing operator intervention and optimizing workflow efficiency.

Furthermore, dynamic programming streamlines the programming process for lights-out operations, minimizing the time and effort required to program parts. By automating code generation and eliminating redundant tasks, skilled programmers can maximize their productivity and focus on strategic initiatives.

In conclusion, dynamic programming represents a monumental leap forward in CNC automation, transforming manufacturing processes and driving efficiency gains. With GF Machining’s cutting-edge controls and innovative features like dynamic programming, the future of automation in manufacturing is brighter than ever.

Original source from MMS