Revolutionizing Aerospace Manufacturing: Ecor International’s Cutting-Edge 3D Printing Solutions

The profound expertise in Additive Manufacturing processes at Il Sentiero International Campus, an Industrial Research Centre established by Ecor International and based in Schio, Magreta, and Modena, sets Ecor International apart as a leader in the Veneto and Italian aerospace industries. They offer bespoke solutions tailored to each customer’s specific project and component requirements.

Rinaldo Rigon, Ecor International’s Core Processes & Competences Manager, explains, “We start by addressing the customer’s needs, and through our collaboration with Il Sentiero International Campus, we can initiate a customized research project to evaluate and provide the most sustainable and effective solution.”

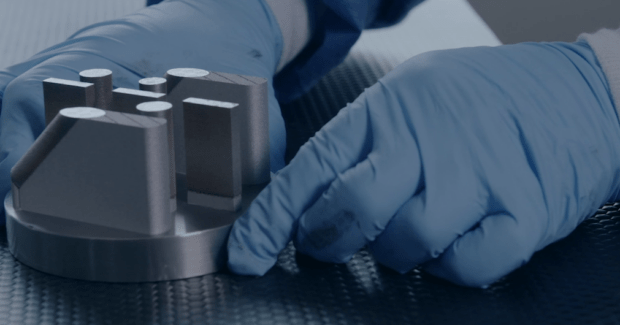

In the production of aeronautical components, researchers and engineers at Il Sentiero International Campus utilize 3D printing technology to fabricate inspection jigs that faithfully replicate the parts requiring specific precautions. By integrating 3D printing into the manufacturing and welding processes, the production of aerospace components achieves increasingly superior quality outcomes.

Additively manufactured parts play various roles, from facilitating the alignment of two components for specific welding positions to overseeing free surfaces and ensuring safe packaging during transport. For components requiring specific angles or orientations, 3D-printed tools provide support and ensure correct positioning during welding. Even in specialized processes like resistance welding, the research center’s 3D-printed tools guarantee precise targeting.

An exemplary component that undergoes these processing steps in Ecor International’s Aerospace department is the fuel tube of the Frecce Tricolori, which demands extreme precision and evenly spaced points.

In cases of free surfaces, such as parts with irregular shapes or curved surfaces challenging to manufacture, 3D printing technology simplifies the measurement and shape control process even before welding. This is especially evident in components for air transfer and cooling in aircraft, where Ecor International ensures precise fluid-dynamic performance aligned with the unique geometry of these freeform and contoured surfaces.

Mario Franchi, Il Sentiero International Campus’s Additive Manufacturing Laboratories & Technologies Research, emphasizes, “The design of the 3D printing process is one of our most powerful tools for delivering personalized services to our end customers.” They manufacture consistently unique parts, offering solutions to novel and highly specific requirements swiftly. With the additive manufacturing process, they can hold what they’ve designed within just a few days.

For more information, visit www.ecor-international.com and www.ilsentierocampus.com.

About Ecor International Group: Ecor International S.p.A. specializes in the design, production, and assembly of manufactured products using cutting-edge production technologies in the mechanical engineering sector. In 2017, it established Sentiero International Campus S.r.l., an industrial research center equipped with technical and scientific expertise and state-of-the-art equipment across various market sectors, including automatic machines for processing, packaging, and advanced mechanics.

Original source from www.fabricatingandmetalworking.com