Renishaw’s RCS Product Line: Revolutionizing Robotics Automation for Improved Efficiency and Productivity!

By Ashutosh Arora

Renishaw, a leader in precision engineering and automation solutions, has introduced its RCS product line to address key challenges faced by industries using robotic systems. The RCS series is designed to streamline robot setup, calibration, and maintenance, providing a significant boost to operational efficiency, accuracy, and repeatability in industrial automation. This new offering is set to transform how robots are integrated and managed in manufacturing processes, helping businesses reduce downtime and improve overall productivity.

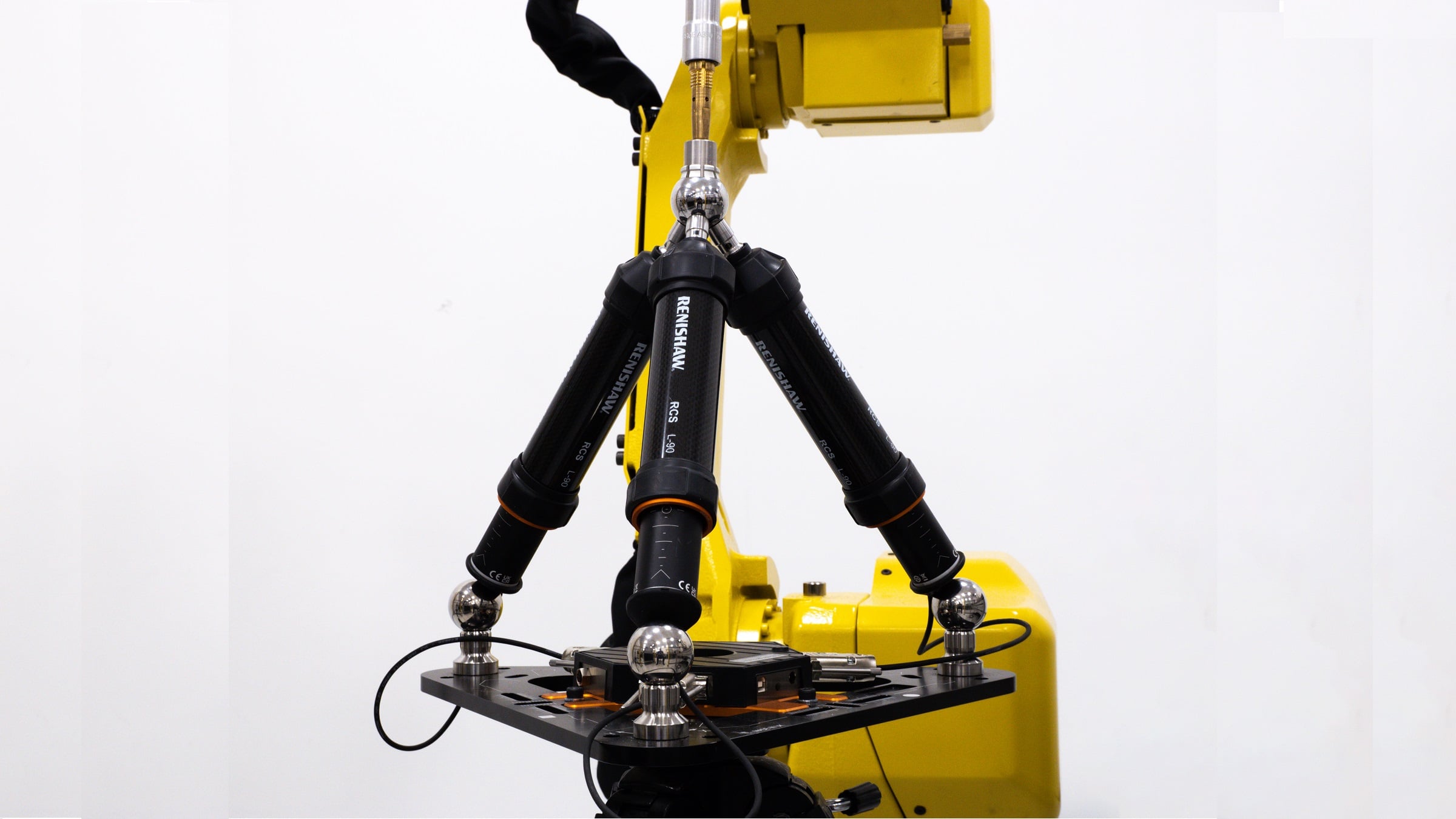

The RCS product line includes three innovative products: the RCS L-90, the RCS T-90, and the RCS P-series. Each of these products is equipped with advanced technologies such as sensors, controllers, robotics, and sophisticated software, all aimed at enhancing the performance of robotic systems. These solutions are specifically designed to solve the challenges of manual intervention, ensuring that robots can be more reliable, easier to manage, and capable of performing with minimal human oversight.

One of the flagship products in this line is the RCS L-90 ballbar, which improves the accuracy of robotic systems by reducing deployment time and monitoring robot health. The L-90 ballbar runs simple routines controlled by its accompanying software suite, which makes it easier to identify and address any performance issues. This results in more precise operations, ensuring that robots perform at their best over extended periods. The ability to monitor robot health in real-time also helps anticipate potential failures before they occur, preventing costly downtime and disruptions.

The RCS T-90 system is another key product in the RCS line. This advanced tri-ballbar system enables robotic users to identify the root causes of poor performance by conducting in-depth tests. These tests include remastering joint offsets, recovering from master errors, and plotting 3D path performance. With the T-90, users can gain a clearer understanding of the underlying issues that affect robot precision, allowing them to make necessary adjustments to improve performance. The ability to perform comprehensive tests and gather critical information in real-time enhances the robot’s operational lifespan, ensuring that they continue to deliver high-quality results for longer.

The RCS P-series completes the lineup by integrating Renishaw’s permanent probing solution within a robot cell. This product facilitates in-process metrology, enabling automatic recovery of robotic applications following collisions or other disruptions. This makes it an ideal solution for industries where continuous, high-precision operation is critical. By implementing automated recovery features, the RCS P-series minimizes downtime and ensures that robotic processes continue to operate efficiently even after a disturbance, reducing the need for manual intervention.

All of these products are supported by Renishaw’s intuitive RCS Software Suite, which provides easy integration with robots from a wide variety of manufacturers. Whether used for simple setups, health checks, or recovery processes, the RCS product line helps companies simplify robot management and optimize performance across their automation systems. This is especially important in fast-paced manufacturing environments where minimizing downtime and maintaining operational consistency are key factors in overall productivity.

In addition to enhancing robot performance, the RCS series also supports businesses in optimizing resource efficiency. With fewer manual interventions and better performance tracking, these tools enable more sustainable manufacturing processes. The RCS products not only improve accuracy but also contribute to cost savings and higher production outputs by reducing machine downtime and the need for frequent repairs.

In conclusion, Renishaw’s RCS product line is a groundbreaking solution that elevates the capabilities of robotic systems in industrial automation. By addressing critical challenges such as accuracy, repeatability, and recovery after disruptions, the RCS series enables businesses to run more efficient, sustainable, and cost-effective operations. As industries continue to integrate more robotics into their workflows, tools like the RCS products will be essential for maintaining high-performance standards and ensuring long-term success in the competitive world of manufacturing.