Paperless Parts and MSC Industrial Supply Co. have developed TechMate

In the machining business, asking for help makes the industry vulnerable to a certain extent. We live in an era where the speed and specificity of technical expertise are being halted to respect the confidentiality concerns of most machining customers. One of the reasons keeping confidentially has become a norm in the machining industry is the increasing value of being first to the market.

Sharing a customer’s drawing on any platform is a risky move since you have no control over who gets access to these drawings; it could be your customer’s competitors who may use these drawings to copy or replicate their technological advancements.

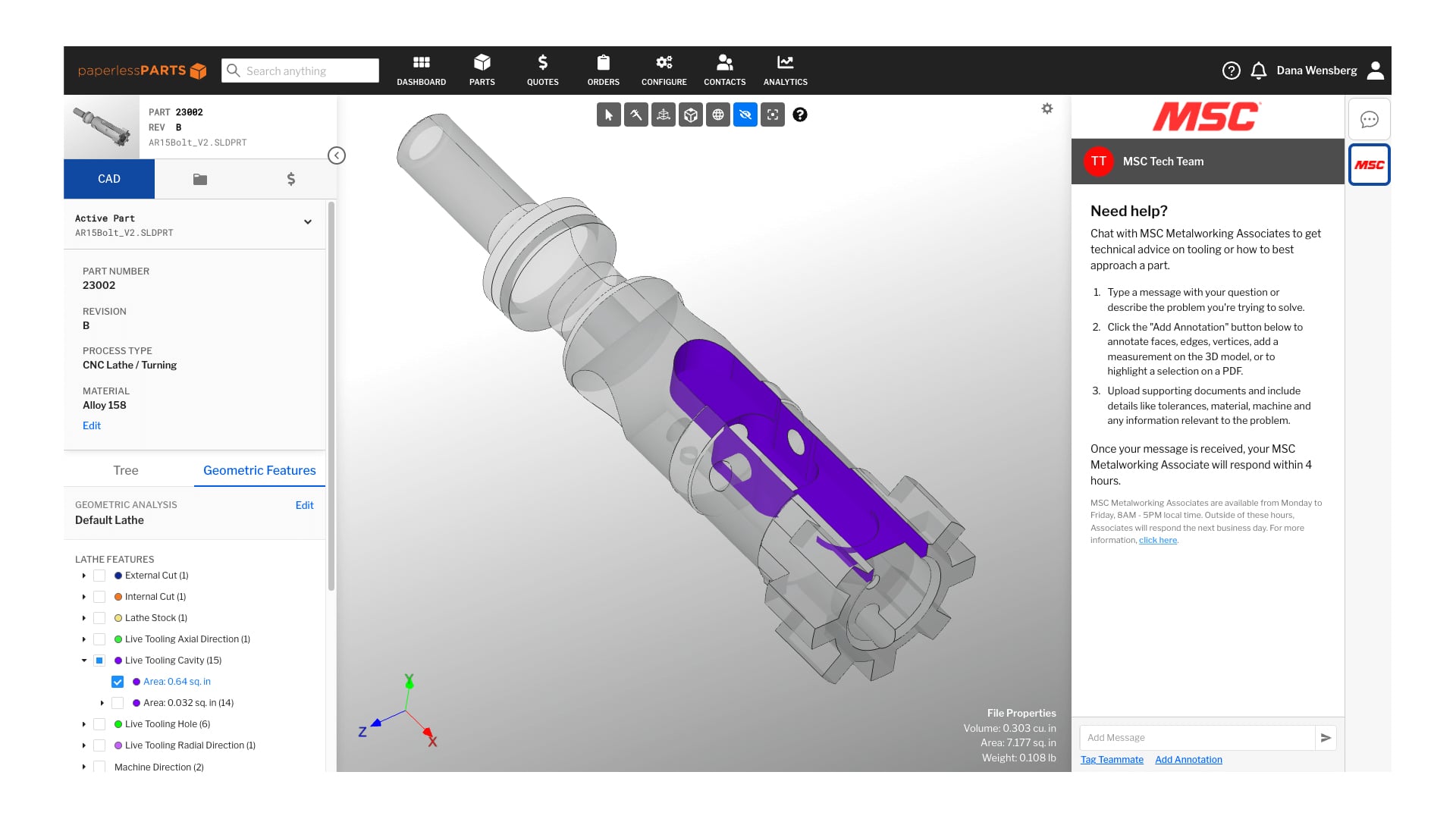

Paperless Parts and MSC Industrial Supply Co. have developed TechMate, a software that enables the secure sharing of part information while seeking expert advice. Remember, Paperless Parts is a pricing platform for machined parts that allows shops to quote jobs effectively and faster.

On the other hand, MSC is a distributor of several consumables used in machining, including cutting tools from a number of providers. So, TechMate is essentially a secure link between the Paperless Parts software and MSC. A user using this software can now share any resources with any MSC expert without being worried about them being used outside the ITAR-compliant environment.

Jamie Goettler, MSC’s senior director of metalworking sales and innovation, says that the covid19 pandemic helped accelerate the creation of this solution. The pandemic has made everyone get used to virtual communication, so adopting this platform has been smoother than it would have been during the pre-pandemic days.

He went on to say that as the software gets better and more secure, more shops will probably be willing to share more information, and MSC can also go further in the information it might ask for. Goettler also hopes that this solution goes beyond job shops in the future. He expects different kinds of other shops to take advantage of this solution as remote access to expertise becomes widely accepted in the industry.