Kennametal Expands KenDrill HPR Line with Long-Length Drills for Superior Performance in Demanding Applications!

By Ashutosh Arora

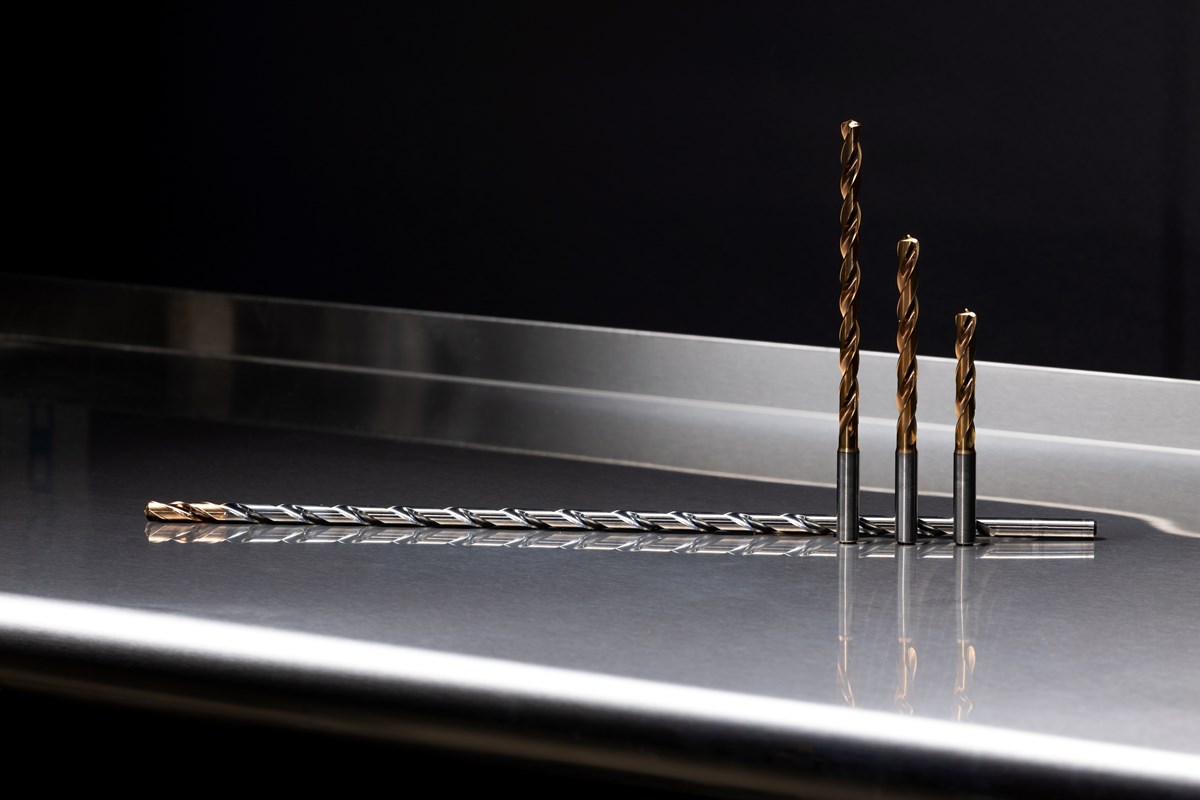

Kennametal Inc. has introduced powerful new additions to its KenDrill HPR Solid Carbide Long Length Drills lineup, bringing 12×D and 50×D drilling solutions to the forefront of deep hole machining. Designed for shops operating in aerospace, transportation, energy, earthworks, and general engineering, these new drills offer enhanced wear resistance, toughness, and tool longevity, closing a crucial performance gap in the company’s high-performance drill platform.

Engineered for reliability in challenging materials such as steel and cast iron, the upgraded KenDrill HPR drills incorporate a suite of advanced features. These include a 135-degree HPR point geometry with a corner radius, optimized gashing for chip control, and four-margin lands that improve guidance and reduce vibration during deep drilling operations. A key enhancement is the use of KCK10A ultra-fine grain carbide substrate with a newly developed coating, which together boost tool life and hole quality even in high-load environments.

The high-polish flute design reduces friction and improves chip evacuation—critical when drilling to depths as extreme as 50×D. This ensures better hole accuracy, surface finish, and overall process reliability, even during continuous, high-speed production runs.

“Kennametal is proud to close a gap in the KenDrill HPR platform with our latest 12xD and 50xD long length drilling solutions,” said Scott Etling, Vice President of Global Product Management at Kennametal. “These new additions deliver substantial upgrades—longer tool life, better hole accuracy, and consistent performance in tough materials.”

With this latest expansion, Kennametal reaffirms its commitment to innovative holemaking solutions that keep pace with the evolving needs of modern manufacturing. Whether it’s producing precision components for aircraft engines or drilling structural parts for off-road vehicles, the KenDrill HPR series continues to set the benchmark for deep-hole drilling performance and durability.