Driving Efficiency: BMW’s Green Revolution in Automotive Manufacturing”

In the realm of automotive manufacturing, energy efficiency and climate protection are paramount concerns. BMW Group’s Steyr site in Austria exemplifies this commitment, recently replacing electric water heating systems with heat pumps to clean engine components. This bold move has resulted in significant electricity savings of approximately 70% annually, marking a pivotal step towards sustainability.

For years, BMW Steyr has prioritized energetic optimization in production, particularly for core engine components. Gerhard Fuchs, responsible for processes and energy at Steyr, spearheaded initiatives to reduce energy consumption. In collaboration with Ecoclean, the decision was made to equip cleaning machine pumps with variable frequency drives in 2016, setting the stage for further energy-saving measures.

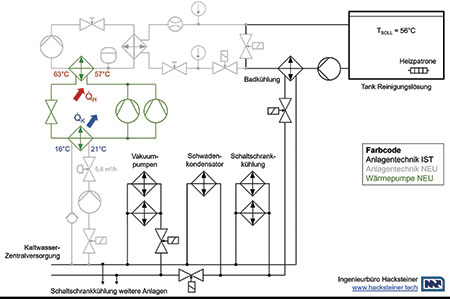

To assess the potential of integrating heat pumps, a neutral engineering office conducted a thorough analysis based on production and energy data. The results were impressive, with estimated energy savings of around 70%. This paved the way for the implementation of a tailored solution, seamlessly integrating heat pumps into the cleaning process.

The innovative solution, customized for BMW Steyr’s needs, involves a heat pump utilizing warm water from the cooling circuit to heat process water for cleaning. The transition from electric heating systems to heat pumps reduced energy consumption from 39 kW to 13.6 kW, resulting in annual energy savings of over 169 MWh.

Implemented without interrupting production, the modification was completed swiftly during a two-week holiday period in 2022. The results speak for themselves, with energy monitoring confirming 100% of predicted savings achieved. Not only has BMW Steyr slashed operating costs by approximately 19,000 Euros annually, but it has also significantly reduced CO2 emissions by approximately 34 tons.

Gerhard Fuchs concludes, “It has been a good decision to involve Ecoclean as prime contractor for energy-efficient projects. We are very happy with the results and their support, and will continue our cooperation.”

BMW’s green revolution in automotive manufacturing sets a remarkable example, demonstrating the industry’s potential to drive efficiency while prioritizing environmental sustainability.

For more information, visit www.ecoclean-group.net.

Original source Engineering Review