Ceratizit End Mills Feature Optimized Tool Geometry for High-Performance Machining!

By Ashutosh Arora

Ceratizit has introduced its new line of OptiLine solid carbide end mills, which are designed to provide high-performance machining across a wide range of materials and applications. The end mills are crafted from premium substrates and feature an optimized tool geometry, making them suitable for both light and demanding operations. Additionally, the specialized Dragonskin coating enhances tool life and performance, making OptiLine a versatile option for various machining strategies.

The OptiLine series is available in four different configurations, including four-flute, five-flute, six-flute, and seven-flute options, each engineered for specific machining needs. The four-flute end mill is designed with a variable helix and pitch, ensuring maximum stability for demanding cutting operations. This design is ideal for achieving consistent results in high-performance tasks. On the other hand, the five-flute version features a constant helix and variable pitch, making it well-suited for a broad range of materials, providing high efficiency and versatility.

For high-efficiency milling (HEM) operations and light finishing tasks, the seven-flute end mill stands out. It is specifically optimized for these applications, with a constant helix and variable pitch design that delivers excellent performance across various metals. The seven-flute configuration ensures high-speed machining with optimal surface finishes.

The six-flute end mill in the OptiLine series incorporates an asymmetrical variable helix and variable index flute configuration, which significantly improves stability during cutting operations. Designed for applications with cutting lengths up to 2.5 × D, the six-flute end mill also features chip splitters, making it highly effective in demanding conditions. This particular model was specifically engineered for use with titanium and super alloys, materials known for their difficulty in machining.

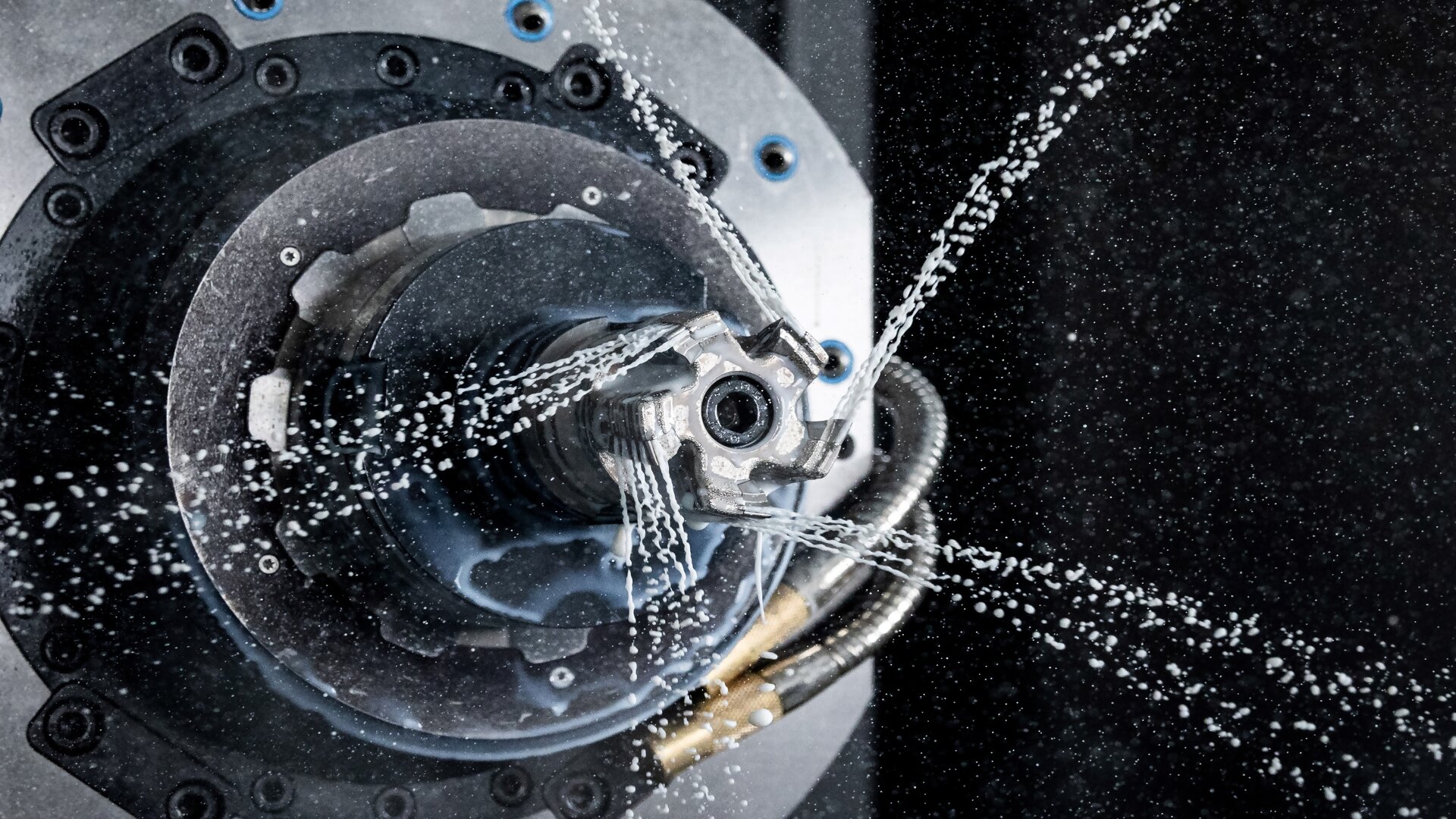

Ceratizit also offers the MaxiMill – 211-DC, an advanced indexable insert milling system designed for heat-resistant materials such as titanium and other super alloys. The MaxiMill – 211-DC features a unique coolant supply system developed through in-house additive manufacturing techniques, including 3D-printed cooling channels. This innovative design directs coolant directly onto the insert flanks, ensuring that the material is kept cool during operation, which helps to increase process reliability.

One of the key advantages of the MaxiMill – 211-DC is its increased tool life—up to 60% longer compared to tools with standard coolant supply systems. Despite the complexity of the coolant channels inside the tool body, the MaxiMill – 211-DC is compatible with standard adapters equipped with through-coolant supply, providing users with a high-performance tool that does not require additional coolant or specialized equipment.

Ceratizit’s OptiLine and MaxiMill – 211-DC series end mills are designed to meet the needs of modern manufacturing, where efficiency, reliability, and precision are critical. By offering a range of tool geometries tailored to specific applications, Ceratizit ensures that its customers can rely on high-quality tools to improve productivity, extend tool life, and achieve the desired machining results across various industries.