Universal Robots Launches UR Studio: Simplifying Robot Cell Customization with Online Simulation Tool!

Universal Robots, a leader in collaborative robotics, has unveiled its latest innovation, the UR Studio, an…

Shops that machine large aluminum parts don’t have to pay millions of dollars for a machining center just to get the work envelope they need. There is a more affordable alternative, and it’s manufactured in the USA.

There are some amazing large format 5-axis machining centers on the market these days. They can machine titanium all day long and hold incredible tolerances. The problem is that you may have to spend north of $2 million to buy one. And good luck getting shipment anytime soon.

But what if you don’t need all that? What if you’re cutting aluminum or other free machining materials that just happen to be large?

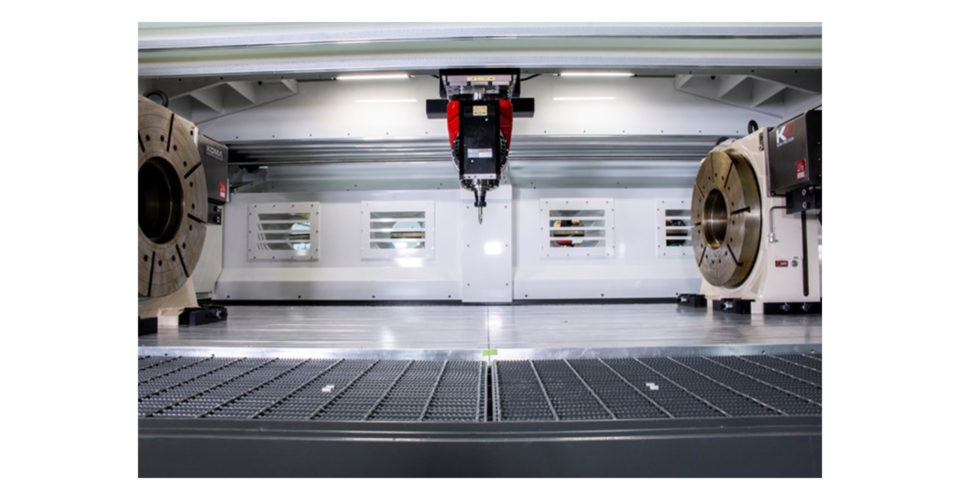

American machine tool manufacturer C.R. Onsrud has an answer for that with its line of large 3- and 5-axis machining centers designed specifically for machining of aluminum and other materials. Will you want to try to cut Inconel or titanium with these machines? Not yet. But if you’re primarily machining large aluminum parts — with prices ranging from under $300,000 to $1.5 million for five-axis machining centers ranging from 144 in. x 60 in. x 41 in. to 100 ft. x 20 ft. x 10 ft. — this is an option you can’t afford to ignore.

Machining Centers for Large Aircraft Parts and More

While the name C.R. Onsrud may be new to you, the company has been around a long time. The Onsrud family has been manufacturing machinery for the aerospace, woodworking, plastics, and composites industries for five generations. While the company still serves these applications, more recent product development has concentrated on building machining centers aimed at underserved portions of the metalworking market, and large aluminum part machining is a big one. All C.R. Onsrud machines are entirely built in the company’s factory in Troutman, North Carolina.

C.R Onsrud machining centers share three things in common: They are big. They are fast. And they are comparatively inexpensive relative to most other like-size machining centers in the market. These machines have 20,000 or 24,000 rpm spindles that can machine at feed rates up 3000 ipm. Rapid traverse rates of 4000 ipm are standard on many models and with high acceleration and deceleration rates, which is particularly important when traversing large distances from one workpiece feature to another or to the tool changer and back.

Standard machines hold ±0.005” or better across the full axis travel range. Optional linear scales and volumetric laser compensation allow tolerances below 0.001”. While that might not sound super precise to some, it is difficult to do much better with very large parts on virtually any machine outside of a closely controlled thermal environment. Remember that these machines are quite large and the coefficient for expansion of steel works out to almost 0.001” per degree change in temperature over a 12 ft. machining bed. Across shorter machining travel distances the standard machining centers routinely hold tolerances to 0.001” or less. All are equipped with Fanuc CNC control systems.

A large variety of options are available for C.R. Onsrud machining centers. All the machines can be equipped with an integrated vacuum work-holding system for fixtureless work holding. Not having to machine around clamps is particularly useful for things like large plate work. They also offer traditional T-slot tables and other fixturing options. Spindle head C-axis capability is available which can be used to articulate auxiliary milling heads or apply multi-spindle options. Large vertical or horizontal rotary tables can be integrated with the machines. In addition, a range of work handling automation can be integrated as well.

C.R. Onsrud machines are routinely used in aircraft applications where up to 90% of the workpiece material is being removed. Standard spindles typically are 15 hp but spindle models up to 75 hp are available. Other common applications include the large battery plates that comprise the bottom of electric vehicles, nested-base machining where multiple parts are cut from a single plate, monolithic structures for buses, RVs and other large vehicles, large aluminum molds, and a variety of defense applications.

C.R. Onsrud offers four main types of machines: enclosed machining centers, linear extrusion processing machines, high rail portal mills for extra-large parts, and traditional open format CNC routers. It will help to get a better sense of C.R. Onsrud’s capabilities for machine shops by taking a closer look at three machining centers designed for cutting large metal parts.

The five-axis machining line starts with the QUBE Series. This fully enclosed vertical CNC machining center has a moving gantry design and provides a large work volume for machining aluminum molds and prototypes, and complex composite or thermoformed plastic parts. A 12 hp, 24,000 rpm spindle is standard, and a 15 hp version is available. The standard model has a 144” x 60” table with 41” of Z travel. The side panels are removable so even larger parts can pass through to be accommodated. It comes equipped with a Fanuc 31i-B5 control.

QUBE Series machines can be equipped with automatic tool measurement and on-machine probing capability which can be particularly useful with large parts for on-machine quality validation as well as establishing workpiece offsets to speed setups. It can also be fitted with an MQL (minimum quantity lubrication) delivery system. MQL is important for high speed machining of aluminum to enhance tool life and resist built-up edge on an insert or solid tool. It also creates far less cleanup of the part after machining and dealing with changing over of coolant tanks.

QUBE Series 5-axis machining centers start at about $260,000.

Be first to see all the updates from MTDCNC

Our newsletters frequency varies dependant on content

All the latest deals from the industry feature on our newsletters