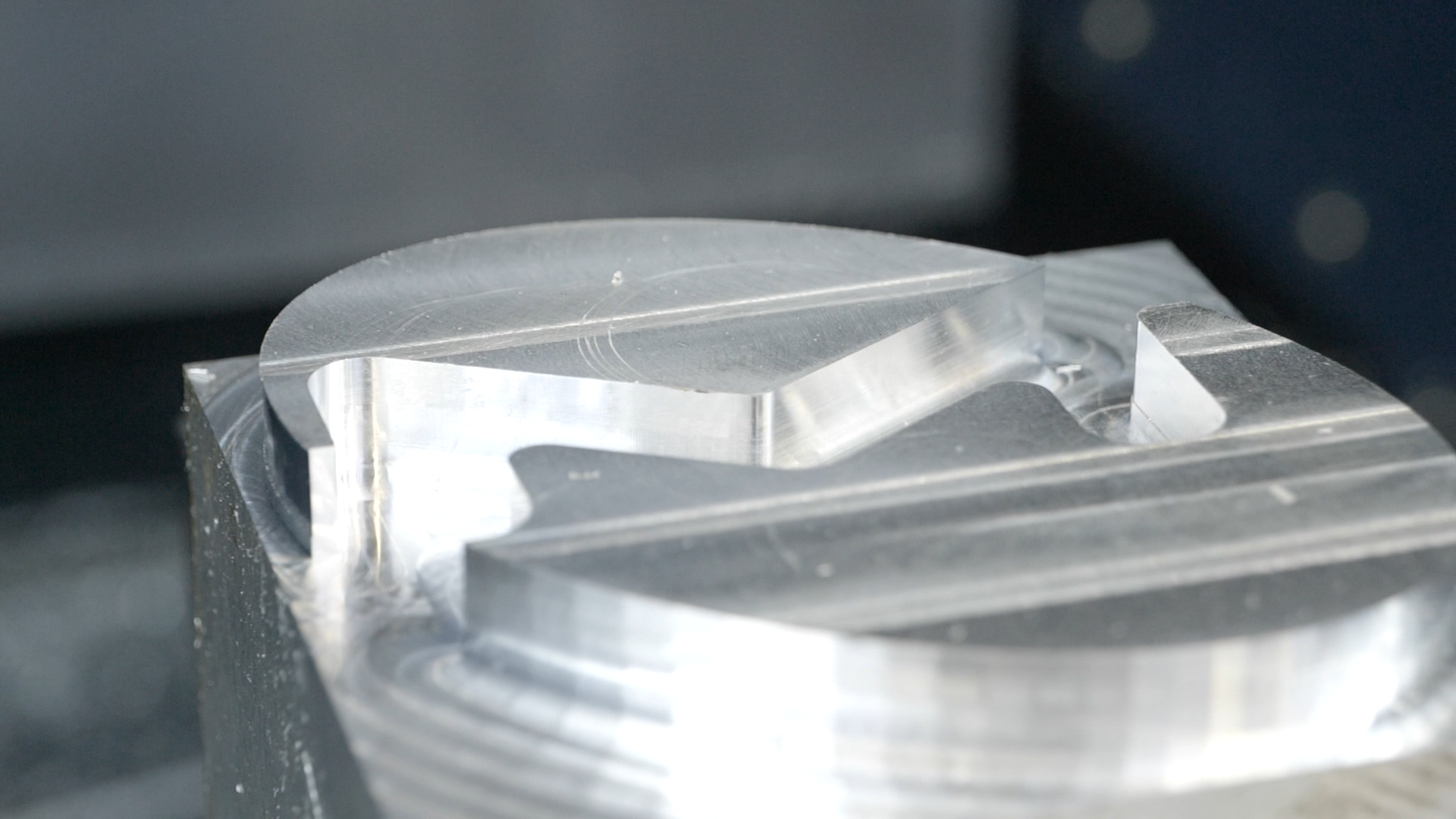

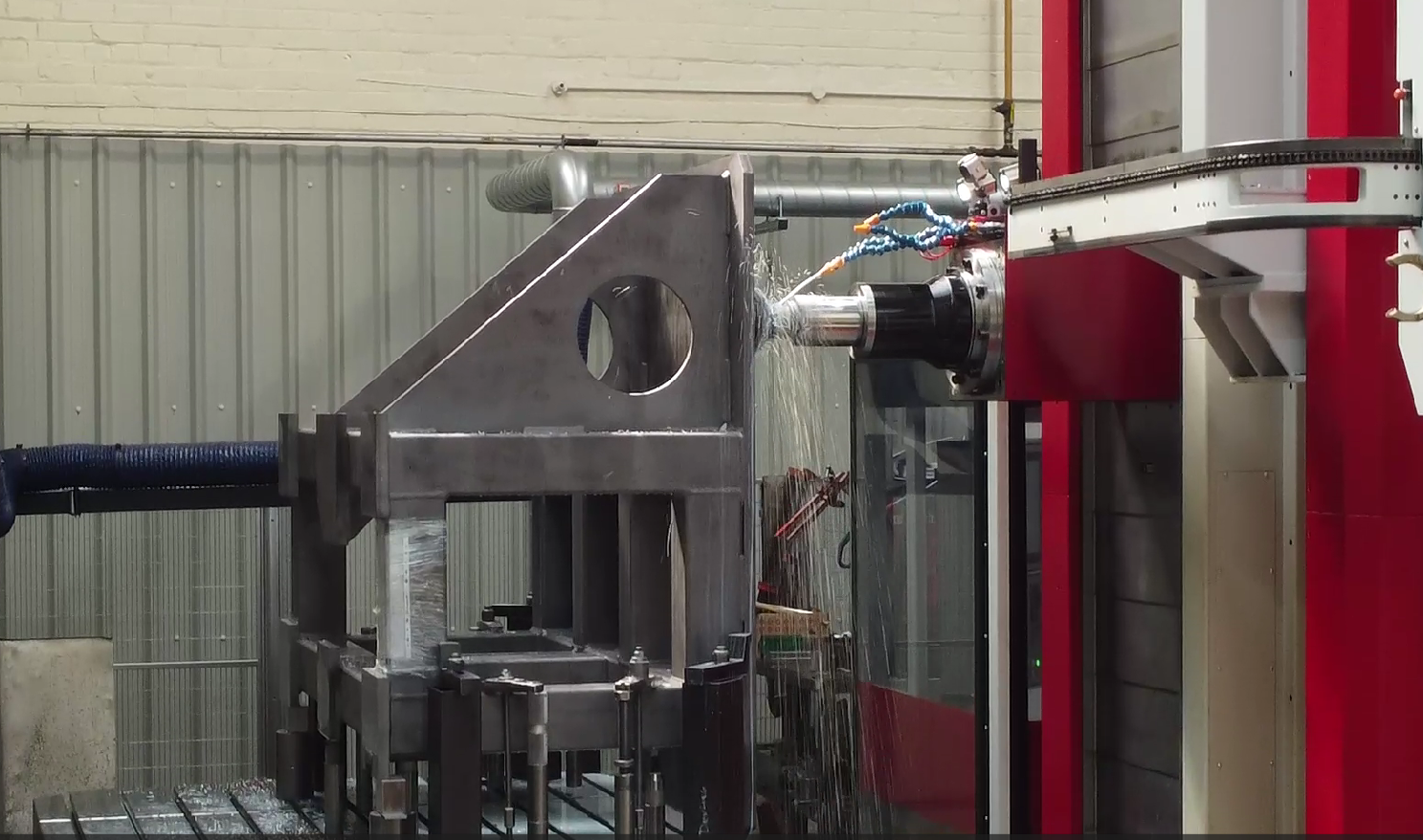

If you’re manufacturing large complex components look no further – we have the perfect machine for you. Introducing the FH1250SX-5axis horizontal machining centre by Toyoda, offering many advantages to all U.K. manufacturers wanting quality and precise parts.

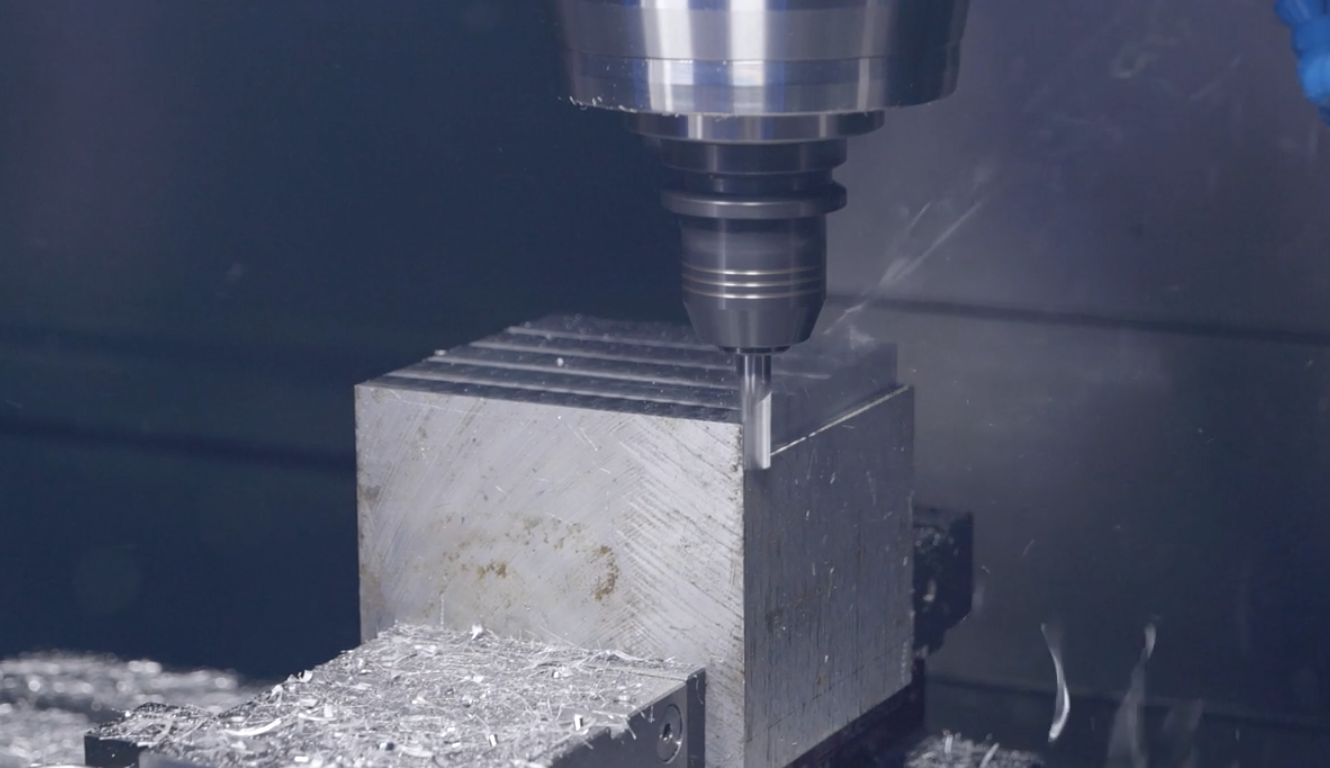

It features a 10,000 RPM, 30kW high torque integral tilting spindle for those complex and precise parts, with rapid feedrates of 32 M/min on the X and Y axes and 42 M/min on the Z axis. For best use of such a large and strong machine, its features allow manufacturers to select a pallet size of up to 1250 x 1650 mm and the pallet work load up to 5,000 kg.

To enable this versatile machine, capable of carrying out multiple jobs, to work to its best capability, it has an ATC capacity starting from 40 tools increasing up to 330 tools, depending on each individuals requirement.

Watch the video below to see the FH1250SX-5axis at work.

Toyoda is an established Japanese manufacturer and has a long-time presence in the U.K. It’s horizontal machining centres are on the leading edge of metal cutting technology. Toyoda offers a full line of machines from rapid processing of small-to-medium size parts to highly precise machining of large workpieces. Their reputation for being a premium brand for manufacturing complex components is still considered one of the best throughout the world.

For more information on Toyoda visit www.leadercnc.co.uk or alternatively follow us on our social media channels for regular updates.