2020 presented each of us with challenges well beyond anything we had experienced before. Securing orders at a time of such uncertainty, coupled with no physical face to face customer engagement presented its own unique hurdles.

At KUKA Systems, we have a sales team and structure that enabled us to adapt and formulate a different approach, that supported the realization of business opportunities. In turn providing the foundations towards a successful 2021 – Our customers responded positively throughout, and fully subscribed to our new methods of communication and discussion.

Diligence and understanding are always a key consideration when qualifying complex technical projects, and proactive input from both sides of the discussion is essential. Dialogue is always aimed at ensuring that no stone is left unturned, ensuring that ultimately a successful project is delivered to the satisfaction of both the customer and the supplier, KUKA Systems.

Whilst many of us had used Skype, Facetime or other online platforms to communicate with friends, family and occasionally work colleagues, the immediate availability of such platforms as Microsoft Teams, proved invaluable; being able to hold constructive technical and commercial discussions and being able to include other colleagues no matter their location, whilst sharing resources virtually. This enabled KUKA Systems to provide the customer a level of confidence and assurance that our proposed solutions(s) met their exacting requirements, both technically and commercially.

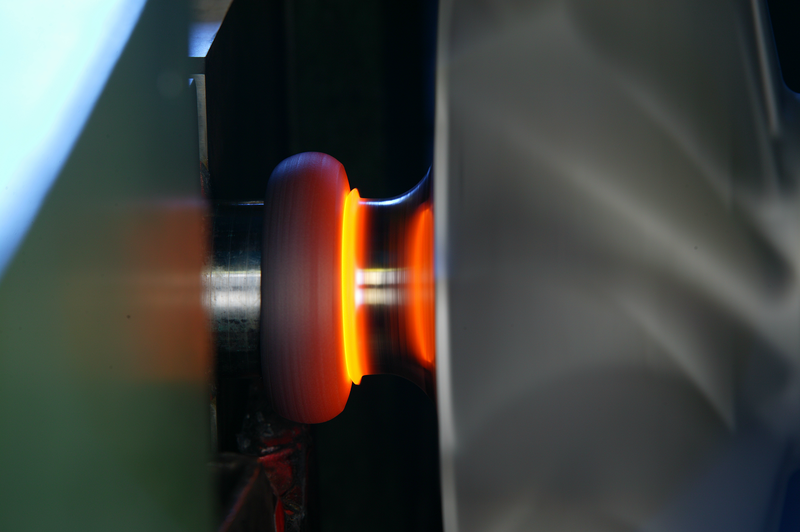

Having delivered solutions to every part of the globe, KUKA Systems has a strong reputation in the drill pipe, piston rod and axel markets. Two projects in 2020 were realized in these sectors, in very different parts of the world – one destined for South Korea and delivered to an existing customer. The other delivered to a new customer in Finland.

To have an existing customer reinvest in your product, and a new customer also invest in your manufacturing expertise is a perfect combination. Whilst these projects have been won in what some may call our ‘traditional’ markets, KUKA Systems Ltd. have also successfully won an order for a solution for which we have solid experience within a fast-growing sector – the joining of dissimilar metals, in this case aluminum and copper, to be used for electrical connections, a combination that is currently used within the Electric Vehicle (EV) market, as an example.

The KUKA Systems team have adapted to the ever-changing conditions in which we have been operating, and we feel lucky to have customers who can see beyond today’s challenges and have the confidence in their individual sectors, and in KUKA Systems to continue to invest in the future.

Segment recoveries for various manufacturers are improving, despite continued restrictions. KUKA Systems are here to help customers navigate disruptions, such as that presented by COVID-19. Our friction welding experts are on hand whether supporting an increase manufacturing agility or helping to realize a vision for production realignment.