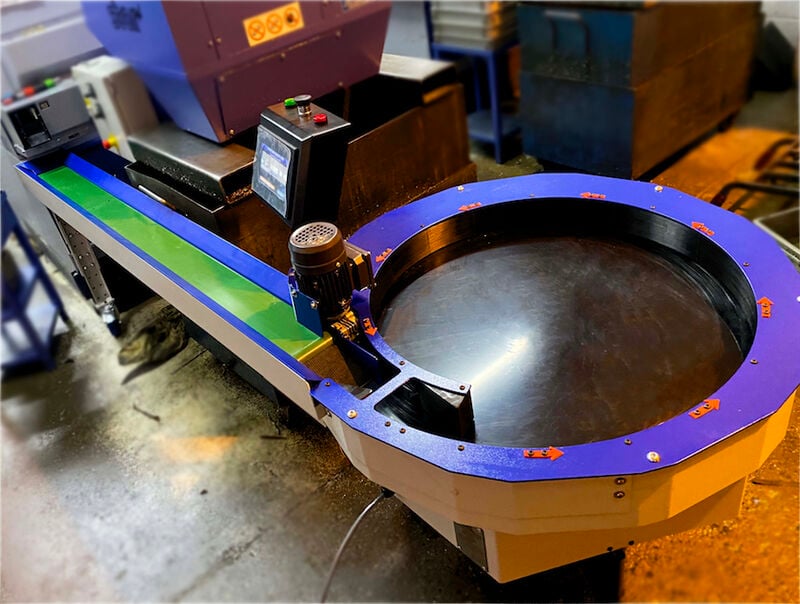

Gas control equipment company Gas Arc have recently invested in an Aryma 61 swarf spinner from J & S Engineering.

Some of the company’s manufacturing involves brass with special additives. When it comes to dealing with their metal swarf however, Gas Arc were encountering a problem with recycling this waste material. If the special brass is mixed with any of the other metals for disposal then the entire quantity of swarf becomes worthless due to cross contamination. Additionally, the brass itself, if recycled alone, has a high recycle value so reclaimed revenue opportunities were being missed.

‘The swarf centrifuge product range that J & S source from our supplier Rimann AG in Switzerland, enables us to provide compact and easy to install solutions to problems like these.’

Gas Arc are now able to spin their special brass separately so the spun swarf is of a high recyclable quality.

The centrifuge was supplied with a fine mesh filter inside the drum, so the cutting fluid can also now be reclaimed from the brass swarf. This can then be reused, resulting in additional cost savings.

An existing gantry system was in-place which the centrifuge was installed to, enabling easy transfer of the swarf to and from the centrifuge.

If you’d like to know more about how a swarf spinning centrifuge could help your business please get in touch with J & S Engineering!