New hybrid milling and grinding machine tool solution reduces process times.

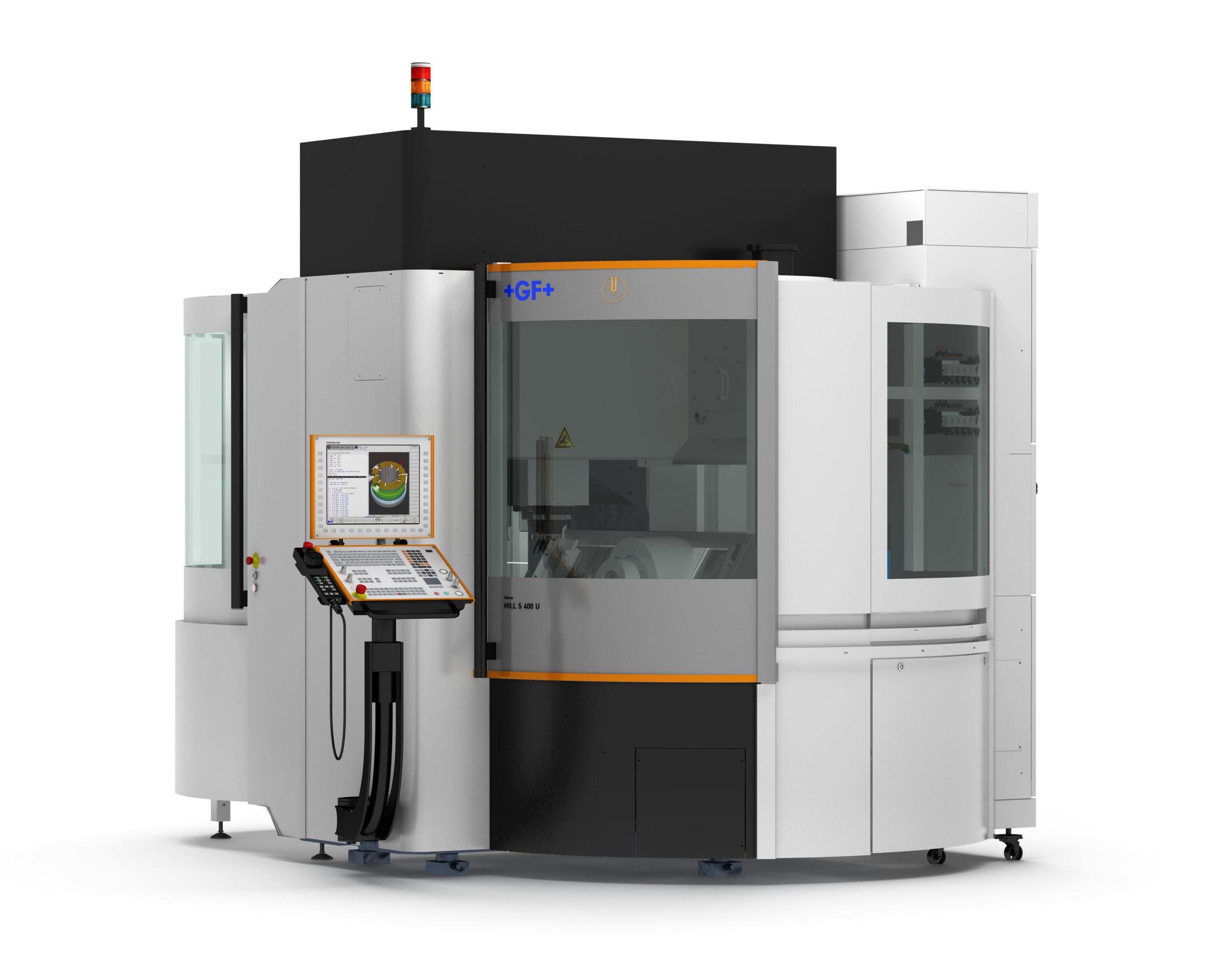

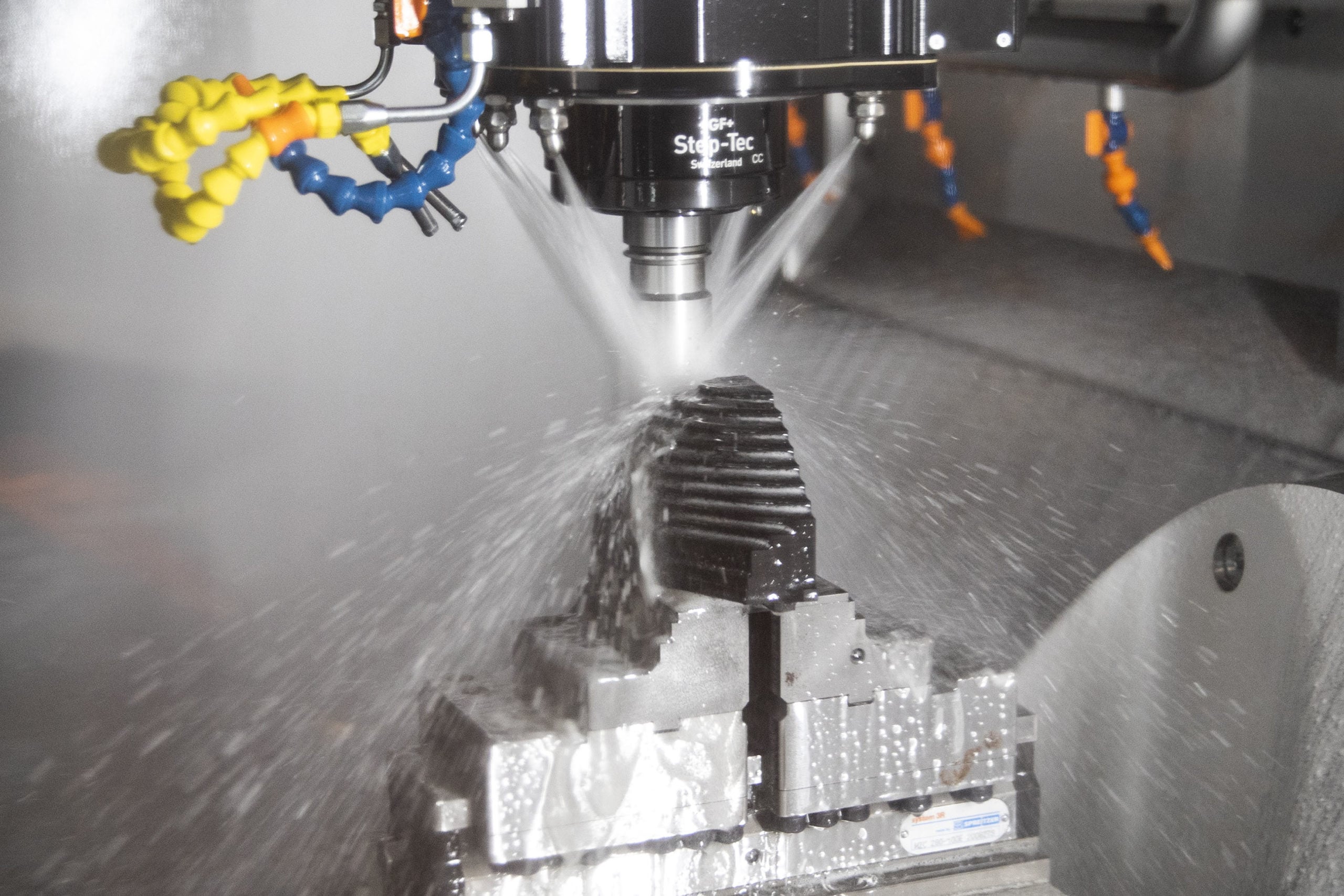

Manufacturers can now achieve faster processing times thanks to the hybrid milling and grinding capabilities available on GF Machining Solutions’ new Mikron MILL S/X (U) series.

The new machines combine milling and jig grinding in a compact footprint.

Faster turnarounds and improved process efficiencies are key features of the new Mikron MILL S/X (U) – an innovative machining centre series that combines milling and jig grinding capabilities within their compact footprints

The 3- and 5-axis machines deliver accuracy, precision, speed and best-in-class ergonomics, Models can operate as standalone machines or, to improve productivity, can be integrated with automation systems to create flexible automated manufacturing cells.

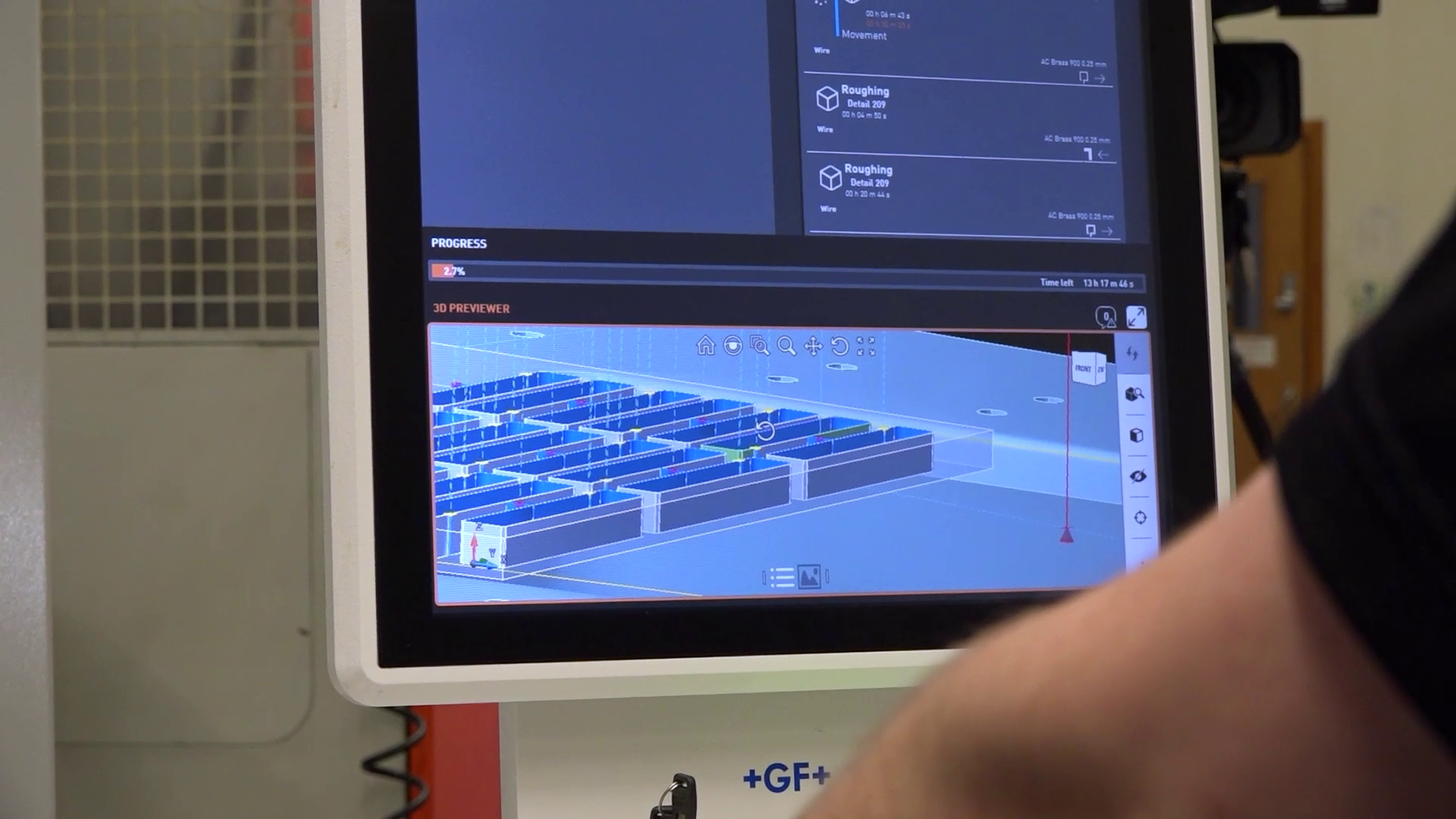

Featuring Automated Machine Calibration (AMC)* and an advanced cooling system, that cools the machine’s structure, spindle etc., ensures that changes in ambient temperatures or heat generated within the work environment during machining operations, do not affect the machine’s ability to deliver high accuracies even during long machining runs or extended periods of operation.

*The AMC package allows operators to quickly, and easily, recalibrate their machine to recover its original precision, at the press of a button.

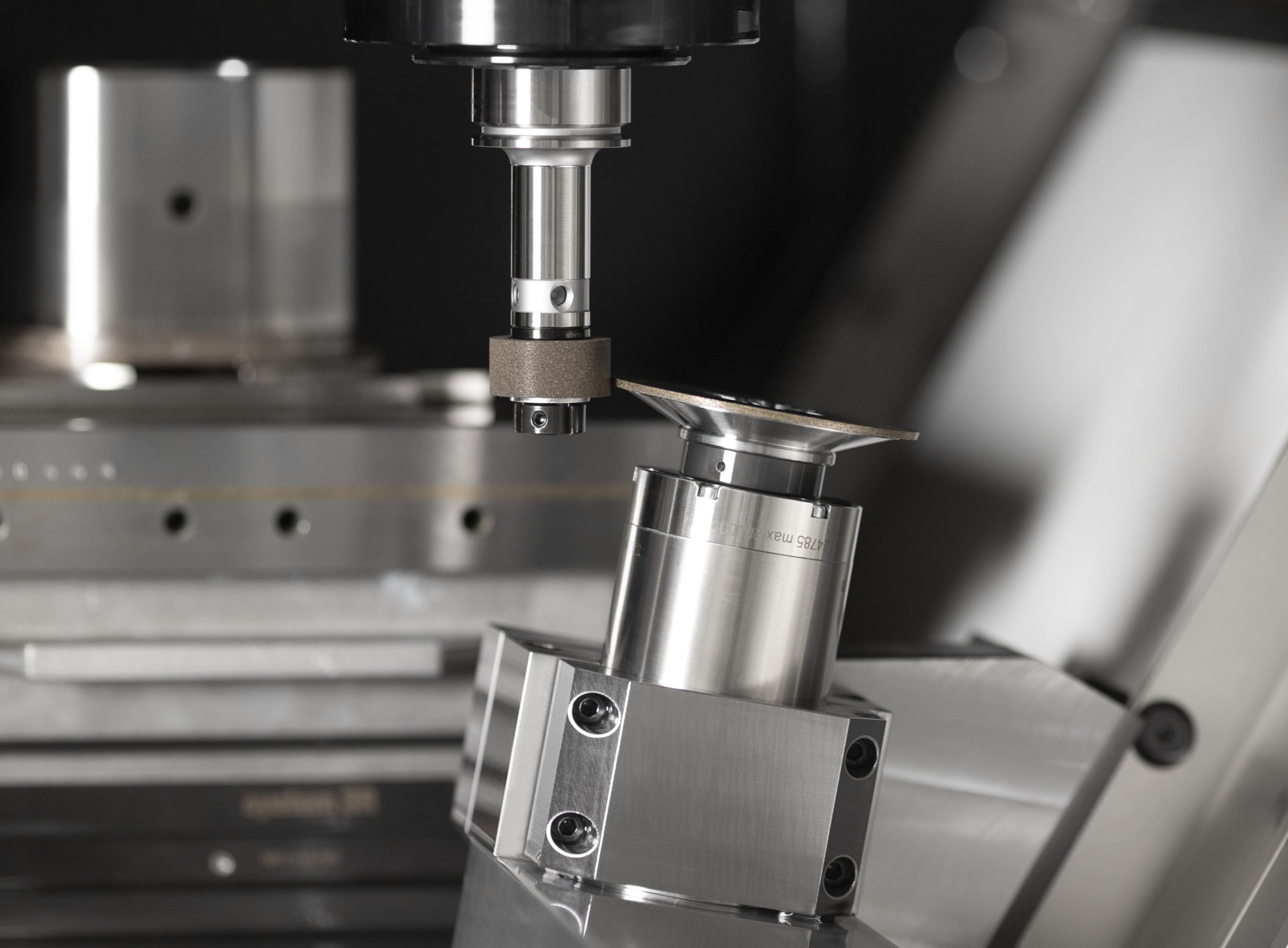

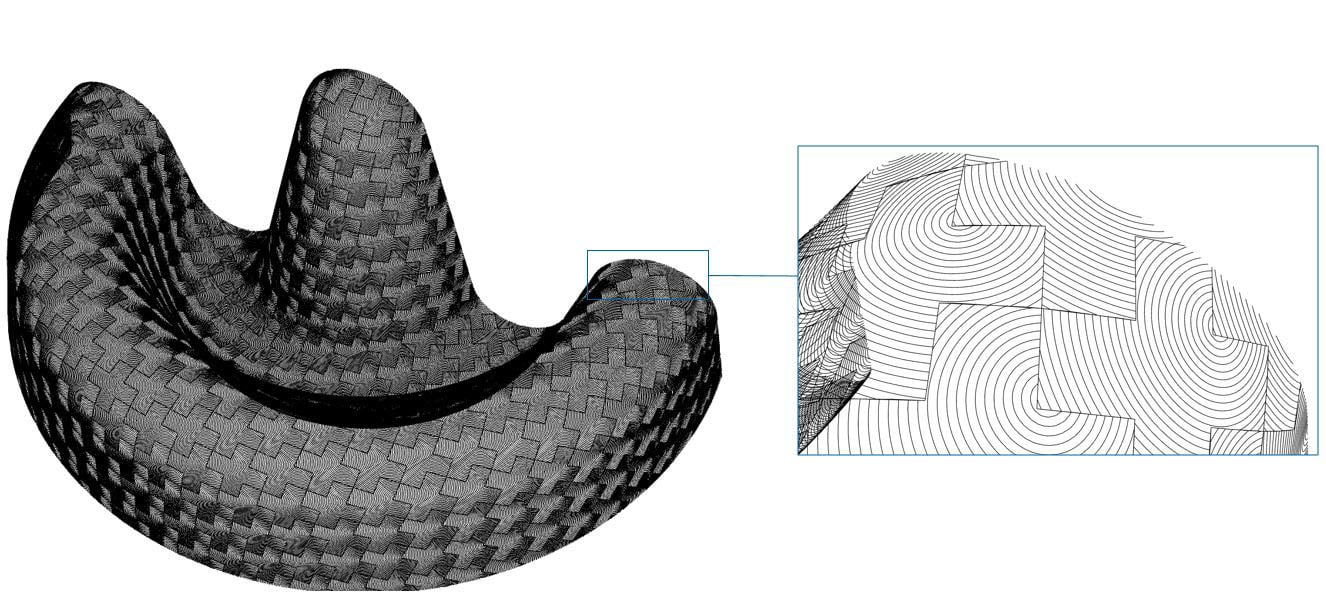

The MILL S and X machines feature hybrid capabilities: milling and jig grinding.

The grinding setup has been accommodated in the machine’s standard footprint and the laser measuring system and dressing spindle (boasting an increased spindle speed from 3,000rpm to 20,000rpm) are located close to the working area to ensure quick and fast grinding.

In addition, the dressing spindle has been installed with a slight inclination in order to be able to dress any type of grinding tool.

The dressing spindle is equipped with an acoustic emission (AE) sensor that tracks and visualises the signal on the Heidenhain control during tool dressing operations.

The machine can be equipped with an additional AE sensor to track grinding operations to optimise the process still further and additional AE sensors located on the machine table, allow operators to adapt the process using the automatic tool detection cycle. This cycle, developed by GF Machining Solutions, avoids air grinding by detecting exactly when the grinding tool touches the part – thereby optimising the process.

With this two-in-one solution, the Mikron MILL S/X (U) series helps reduce part processing times, improve machine shop productivity and efficiencies.