It’s a pivotal time for manufacturing. As an industry, we are in the midst of a technological transformation so profound that many have called it a revolution. It’s been called the era of “The Smart Factory,” or “Hybrid Shop,” or Industry 4.0. However you refer to it, there’s no arguing that recent events have forced us into the future, and the factory of tomorrow needs to exist today.

Smart Factories and Hybrid Shops harness the power of smart technology and innovative manufacturing trends to create data-driven businesses that are more productive and less wasteful than ever before.

Though digital advancements like big data, robotics, and AR have driven this particular manufacturing moment, operating a smart, hybrid-ized shop is as much a mindset as it is an investment in the latest technology. If you’re a machine shop owner, think offense, not defense, in the form of comprehensive transformation that extends all the way to your marketing.

To truly thrive in this new world and economy, you need to take a two-pronged approach: the first is to diversify your service offerings, and the second is digitizing your customer acquisition strategy.

It may sound intimidating, but there are simple steps you can take to get there. My company, DigiFabster, has the privilege of working with AM and CNC shops of all sizes from around the world. Our continuous collaboration with clients gives us unparalleled insight to emerging trends, best practices, and what the future holds for the industry overall. We’ve identified the top trends to guide your machine shop’s transformation into a full-on smart factory.

Why should you “hybrid-ize” your shop in the first place?

The expression “don’t put your eggs all in one basket” may be centuries old, but it’s as relevant as ever—in fact, it’s applicable to your machine shop’s operations, even if you’re already heavily invested in the newest technology. There are certainly benefits to carving out a niche, but if you haven’t found a specialty yet, the good news is you may not have to.

AM, CNC, and 2D are more compatible with each other under the same “roof” than it may seem at first glance

While additive manufacturing is emblematic of the manufacturing industry trends that have fueled this so-called fourth industrial revolution, many of the most successful companies have positioned themselves as a one-stop shop for a range of solutions. Through a combination of AM, CNC, injection molding, and other services, they can offer unprecedented turnaround times, customization, and flexibility.

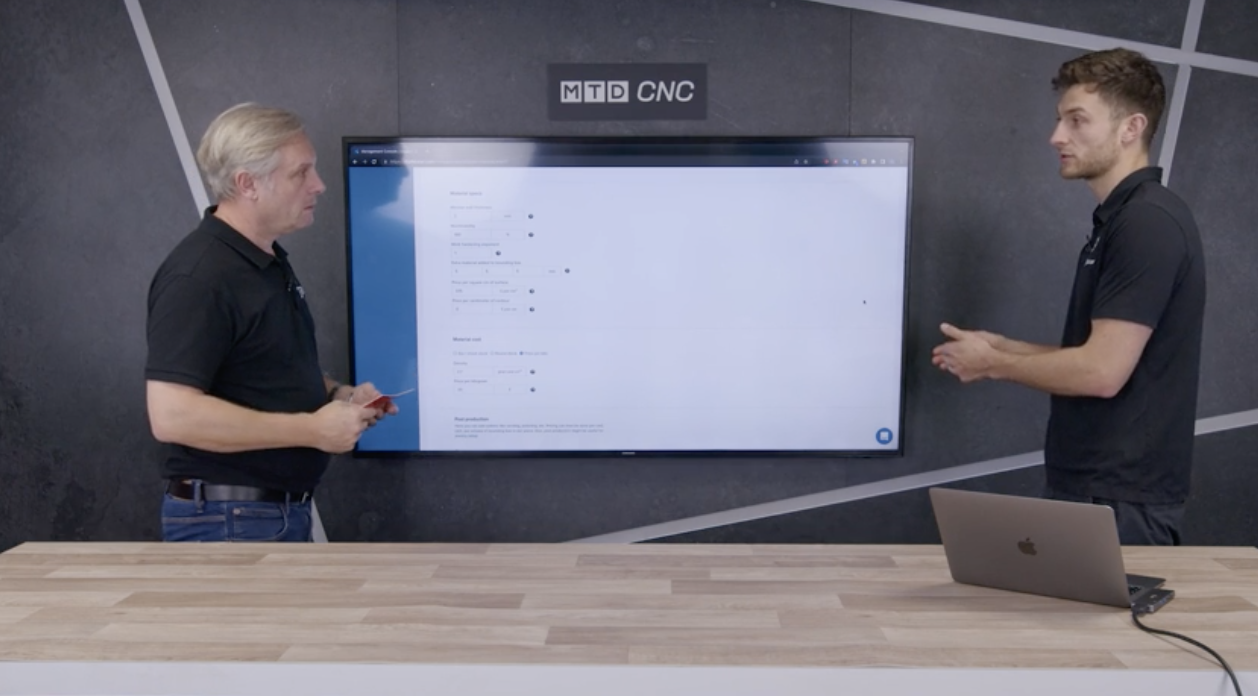

If your AM niche is well-carved-out but you’re having trouble scaling your business, chances are your internal processes — such as quoting and acquiring new customers — also need to be updated with new technology. It’s a golden age for AI-driven, software-as-a-service as well, and machine shops of all kinds can quickly integrate new technology to streamline traditionally labor-intensive, non-billable operations like acquisition and quoting, and grow their businesses substantially.

For traditional shops who haven’t yet moved into new technologies, AM can obviously fulfill new customers’ need for instant gratification, but those shops often wonder what that means for their older legacy clients. From what we’ve seen, those clients are often disrupted by more agile newcomers to the market, so traditional shops should be ready to serve the newcomers with on-demand solutions. The legacy clients will eventually adapt to the new normal over time. Until then, if a shop has automated the process of acquiring and servicing customers, they will ideally have more resources to maintain the personalized, high-touch service for those who are accustomed to it.

Traditional shops are hesitant to invest in new equipment all at once. That’s not a problem; in fact, it might be a more strategic approach in the long run, depending on a shop’s budget and expertise. We’ve found these shops can win and retain new clients by outsourcing to a trusted partner while deciding which technologies to bring in house.

Industry 4.0 impacts sales and marketing, too

Today’s customers have never waited a few days or even a few hours to place an order, so automating quotes and sales is the new standard. Whether insourcing or outsourcing, manufacturers need a marketing strategy that allows them to meet prospects where they are: online.

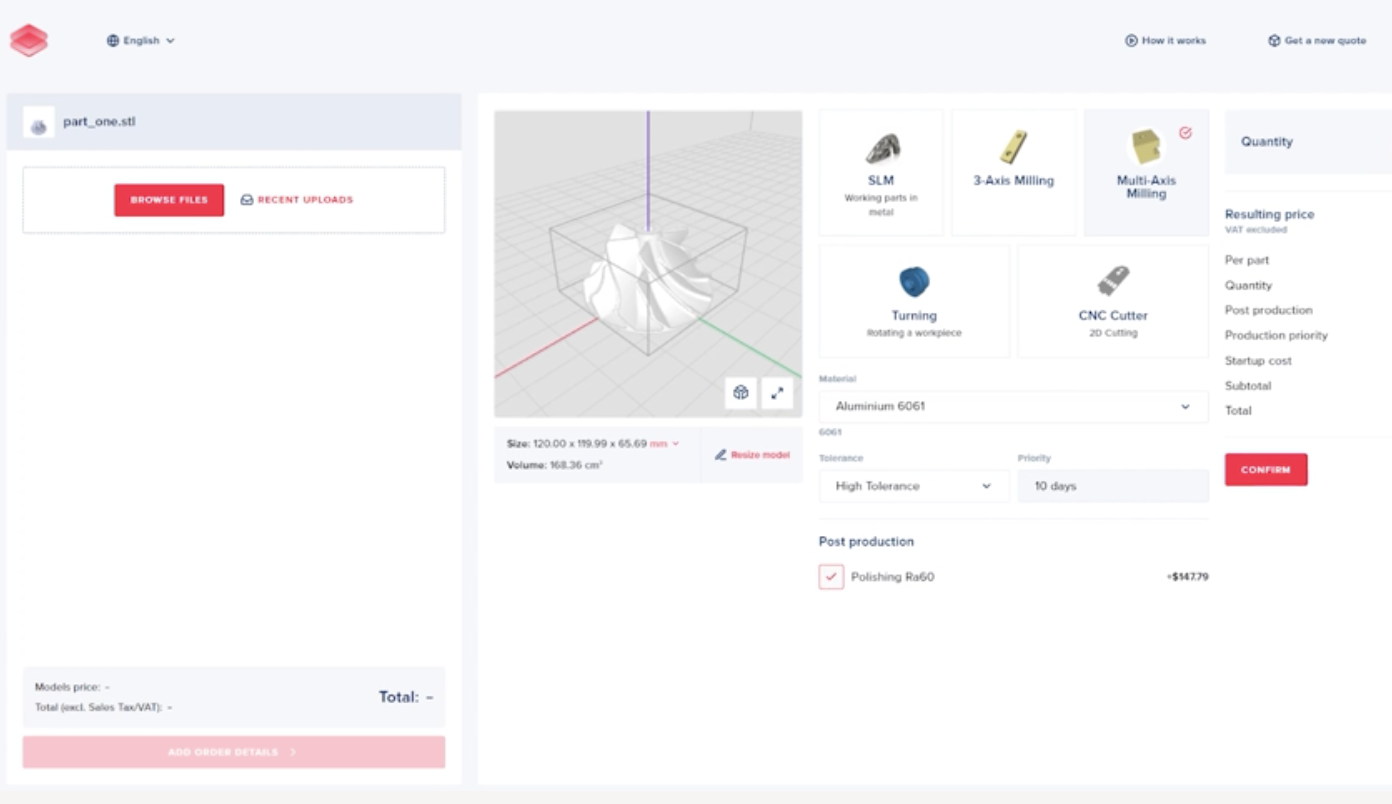

Given that purchasers spend 70% of their time on the internet, no B2B manufacturing marketing strategy — whether you’re doing AM or injection molding — can truly be complete without a digital ordering interface. In shrinking the quoting process from hours to minutes, automated RFQ solutions dramatically cut costs in addition to winning new business.

And shops will need that extra time and money on their hands to truly become a smart factory of the future—in this era of manufacturing, there’s no room for needlessly lengthy processes.