Nuneaton-based Unifabs has installed a brand new AMADA REGIUS high-speed CNC fibre laser profiling centre with load/unload automation and storage. The company is targeting 25% growth in 2022 and says the machine has already improved laser cutting speeds by 50% for certain parts. To further improve its ‘design to delivery’ offering, the company has also placed an order for a new AMADA HRB-ATC, the first mid-range press brake from AMADA that features automatic tool-change capability.

Founded in 2007, Unifabs is a £12 million turnover business with 125 staff that supplies precision sheet-metal parts to a customer base of blue-chip manufacturers from a single site with five factories that total 52,000sq/ft of manufacturing space. “Our goal is to be much more than just a supplier of sheet metal fabrications and parts. We want to be a manufacturing partner, supplying a start to finish service. Whether we’re supplying sheet metal components ‘just in time’ to a manufacturing line, or controlling the entire production process on a contract manufacturing basis, we operate as an extension of our customer’s business,” says Managing Director Tom James.

“We don’t specialise in one particular sector, but strong-performing industries right now include HVAC, catering equipment and construction. To ensure timely deliveries to our customers we continuously invest in the latest manufacturing technology. Even though we have an AMADA FOL-AJ 4kW fibre laser with AS LUL loading system and an AMADA EML-3610NT punch-laser combination with MP loading system, we were still outsourcing a lot of laser cutting,” explains Mr James.

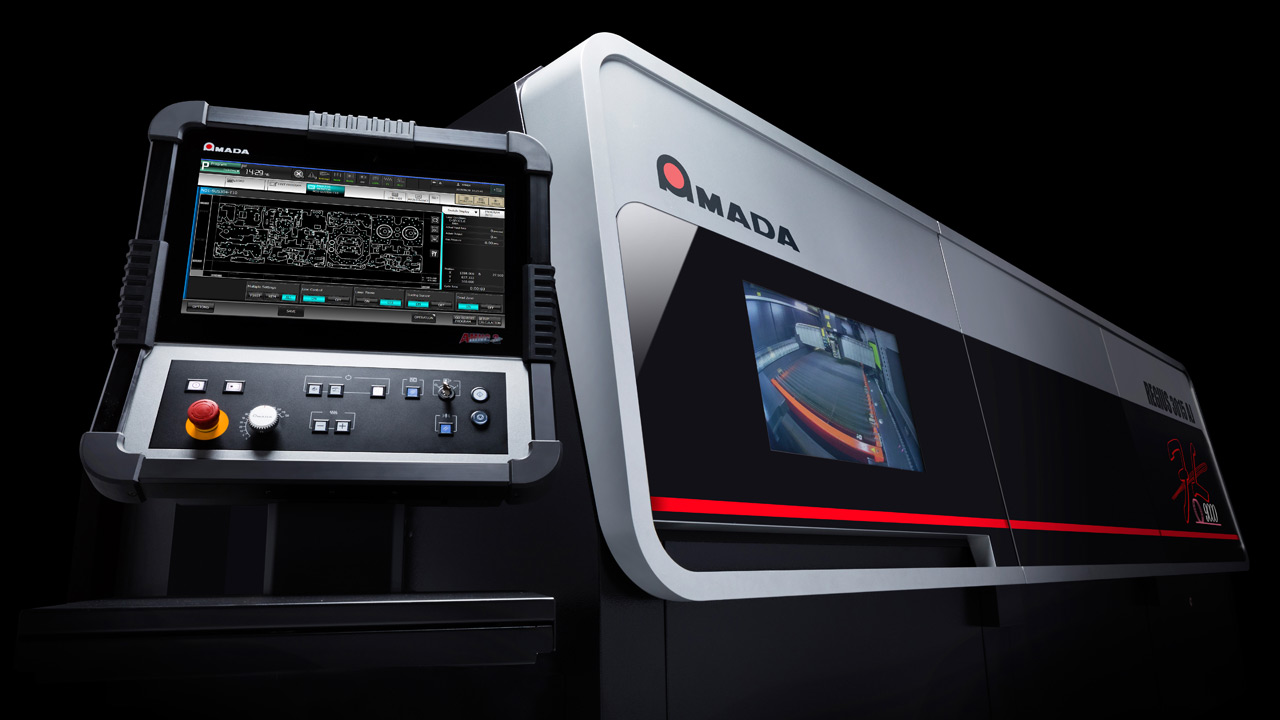

To help improve lead times for its customers and regain control of its parts, Unifabs decided to invest in another laser cutter. “We looked at different models, but along with the increased processing speed we liked the automated setup features on the AMADA REGIUS, which we knew would help to reduce set-up/inspection time and maximise productivity,” he says.

Automatic inspection on the REGIUS utilises technology such as the AMADA i-Nozzle Checker to assess nozzle damage and circularity. If the nozzle requires changing, this will happen automatically via the machine’s 16-station nozzle changer, negating the need for subjective operator judgement. A further function of the i-Nozzle Checker is the automatic alignment of the nozzle centre if/when required.

Installed in November, the AMADA REGIUS is primarily processing mild steel, galvanised steel and zintec from 1 to 8mm thick. The machine features an AMADA ASLUL-3015 for the automatic loading and unloading of sheets and the storage of raw material, ensuring uninterrupted production runs. Typical batch sizes are in the region of 50 to 200. The REGIUS features AMADA’s new i-Process Monitoring system, which checks the wavelength of reflected light in real-time to provide a reliable indication of good or poor cuts. Automatic head collision recovery is a further function of i-Process Monitoring.

The REGIUS CNC fibre laser profiling centre is not only the fastest in AMADA’s portfolio but the first to integrate several key technologies such as linear drives in all axes, the all-new laser integration system and variable beam control technology.

Bending is a core business function, which is why Unifabs has placed an order for a new AMADA HRB-ATC. Adding to the company’s existing seven AMADA CNC press brakes (HFE and HFP models), the HRB-ATC is the first with automatic tool change capability.

“We manufacture a lot of samples, prototypes and small batch runs to help get components ready for serial production. We have 10 people in our CAD team, so a lot of our work comes from the product development side of our business. However, these parts often have long set-up times, so we’re hoping that the new press brake’s ATC capability will have a big impact on throughput in this area. We’ll program a prototype part offline using AMADA software, send it to the new HRB-ATC and hopefully be folding metal within a few minutes,” explains Mr James.