Tracing medical instruments with Laser Lines

With the Coronavirus pandemic having such a significant impact on everyday life, the risk of cross-contamination is an issue where laser technology can offer some assurance and support in the battle against infections.

Offering a range of laser marking systems, Laser Lines Ltd in Banbury has been remarkably busy recently, ensuring the tracking and traceability of medical instruments while they are handled and decontaminated. Reusable surgical instruments are sterilised in both hospitals and centralised decontamination centres; that receive used instruments from nearby hospitals. A new regulation is on the way – and this requires decontamination departments that run these services, to provide comprehensive traceability of each and every instrument as it passes through the cleaning and sterilisation process.

One traceability option is the implementation of a label-based system. However, even the hardiest of labels will deteriorate during the decontamination process, eventually becoming detached and needing to be replaced. With labelling being an unfeasible long-term solution, laser marking comes to the fore as a more cost-effective and reliable solution.

Laser marking solves the problem

Laser Lines has provided laser marking solutions for this application for several customers recently and one prominent example is a company called IHSS. In addition to this work – Laser Lines also work directly with hospital decontamination departments including the NHS Tayside Central Decontamination Unit (CDU) in Dundee – to provide a traceability solution.

Laser Lines provided a Datalogic Ulyxe system to NHS Tayside CDU, which laser marks instruments with a unique GS1 machine-readable DataMatrix code. The Datalogic Ulyxe system conducts laser marking with exceptional speed, whilst also having the facility to add alphanumeric characters and logos.

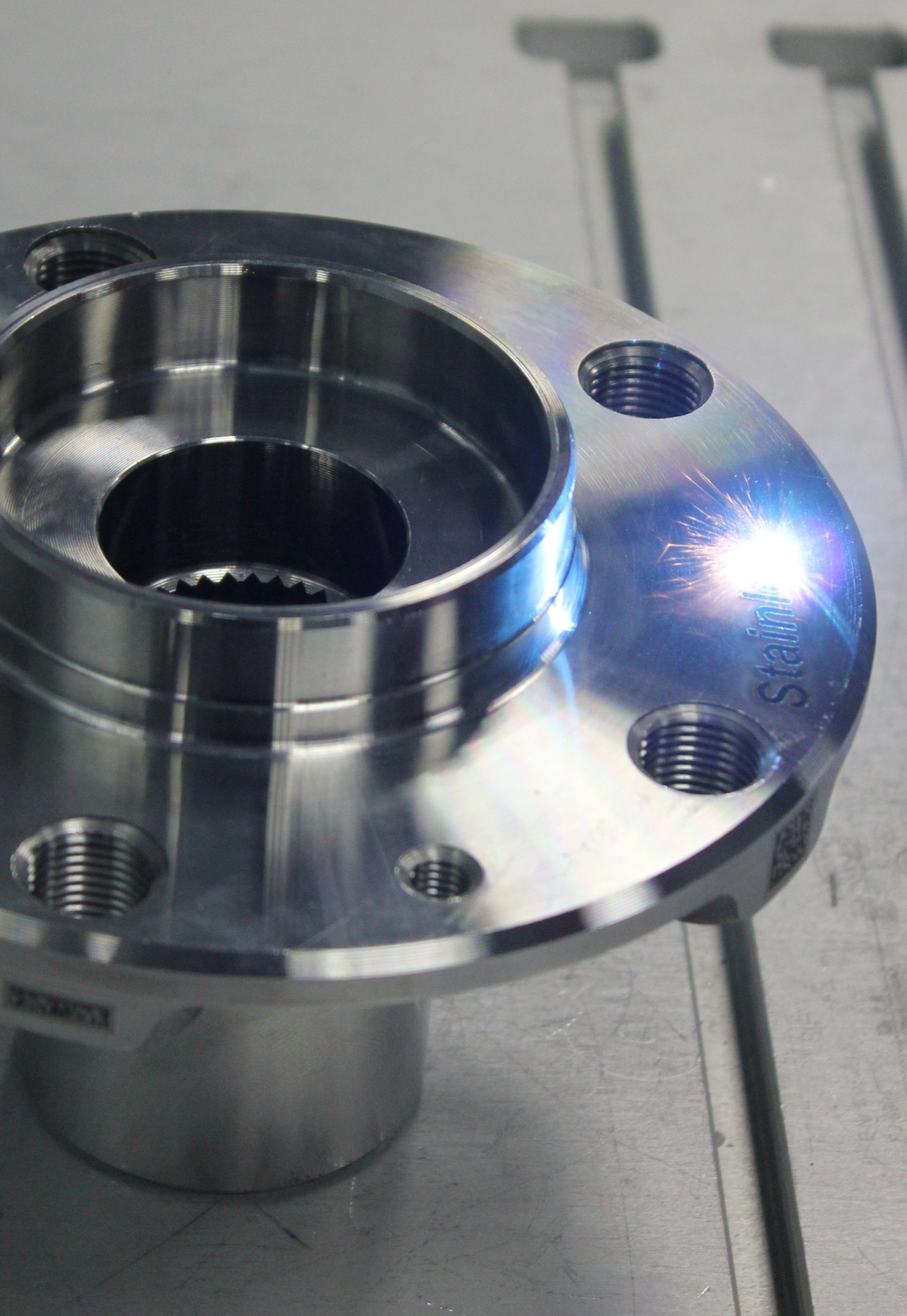

Thanks to this Diode-Pumped Solid-State (DPSS) laser system that delivers a high-frequency short-pulse laser energy, the system does not interfere with the metallurgy of the instruments. This is very important as any impact upon the metallurgical properties may pose a risk to the life of the instruments with corrosion resistance properties potentially being compromised.

Consulting with the customer

After listening to the concerns and requirements of this customer, Laser Lines worked with the hospital partner Sciamed to demonstrate the Datalogic Ulyxe’ capabilities to the Tayside CDU. Laser Lines showcased its capabilities on materials such as anodised aluminium, plastic, titanium and stainless steel – to prove the solution would work.

Now that the system has been installed, NHS Tayside CDU can track and trace the instruments the hospitals use every day through the washing, sterilisation and packing processes – all the way through to being used on individual patients and returned back to the facility for cleaning and sterilisation again.

Not only does this make the health boards processes compliant with the new legislation, it means that should anything be found to be unsafe; the instrument can be traced, tracked and removed from the process chain before it is used on a patient.

Alan Simpson, Quality and Technical Manager at NHS Tayside said: “The use of the laser marking equipment has integrated seamlessly with our tracking and traceability system – and has been an essential asset in ensuring the prevention of high-risk instrument migration.”

Christopher Ogden, Manager of the Industrial and Scientific Laser Divisions at Laser Lines said: “DPSS lasers are one of our most popular laser technologies due to their efficiency, reliability and flexibility. DPSS lasers can be superior to standard fibre lasers for plastic marking and other heat-sensitive applications. Just as we did in this case, we take a lot of time to understand our customers’ requirements before recommending one of the solutions from our wide range of lasers.

Spotting the Advantages of Laser Marking

At IHSS, the challenge was completely different. The company operates four sterile service decontamination facilities that are fully operational 24/7, 365 days a year. Their need was on a very large scale with instruments arriving every day from a multitude of UK hospitals.

Spotting the advantages of laser marking at an early stage, Mr Dean Burand, Regulatory Manager at IHSS, explains: “In 2012, the NICE IPG 196 guidelines were put in place to help improve patient safety and reduce the risk of transmission of Creutzfeldt–Jakob disease (CJD) via interventional procedures. The guidance highlighted the need for tighter control of the migration of surgical instruments. In response to this, IHSS looked at how it could equip its facilities to expand on its traceability system (T-DOC). T-DOC is a leading-edge track and trace system.”

To make the system robust and to offer a solution for both IHSS and its customers, IHSS put into practice a scheme where every ‘high-risk’ surgical instrument that moves through its system, is uniquely identifiable via laser marking. Laser Lines worked closely with IHSS to help them choose the best laser marking system to interlink with their T-DOC system.

“We needed the ability to identify every instrument, so it would link in with our traceability system. Previously, we used barcoded tags, but as part of this initiative, we wanted to offer a ‘best in class solution’, and we’re pretty sure that if we could identify instruments in a different way, the process would be tighter and therefore, the system could be clearer and cleaner,” says Dean.

“There were generic commercial laser marking systems available, but we needed a bespoke solution. We needed a system that would leave a clear, long-lasting mark without damaging the instrument. We knew that some of the laser marking solutions on the market create a mark that is too deep, meaning the instrument could rust and be contaminated.”

IHSS turned to Laser Lines and together they spent a year considering and evaluating the different options. With Laser Lines’ help, IHSS eventually settled on the Datalogic V-Lase 10 system.

IHSS has experience of networking hospitals to its T-DOC system, and currently has over 100 T-DOC stations within the NHS linked to its data centres. Once Laser Lines had installed the laser marking systems and trained the operators, IHSS immediately started batch-marking and registering large numbers of instruments on a daily basis. The new system enabled IHSS to not only register the instrument that was from a specific hospital, but also the ability to match a single instrument to a case and a patient, by providing a unique identifier.

“Laser Lines offered us training and have been a great support over the time we have been working together. The team there took the time to understand our challenge and advised us on getting a longer-lasting system and to ensure the machines were the most effective they could be. We are very happy with the solution and the support we have been given.”