Located in Hinckley, Arrow Precision Engineering has invested in a Studer S41 grinding centre to produce automotive parts. MTDCNC visited the Leicestershire company to find out more.

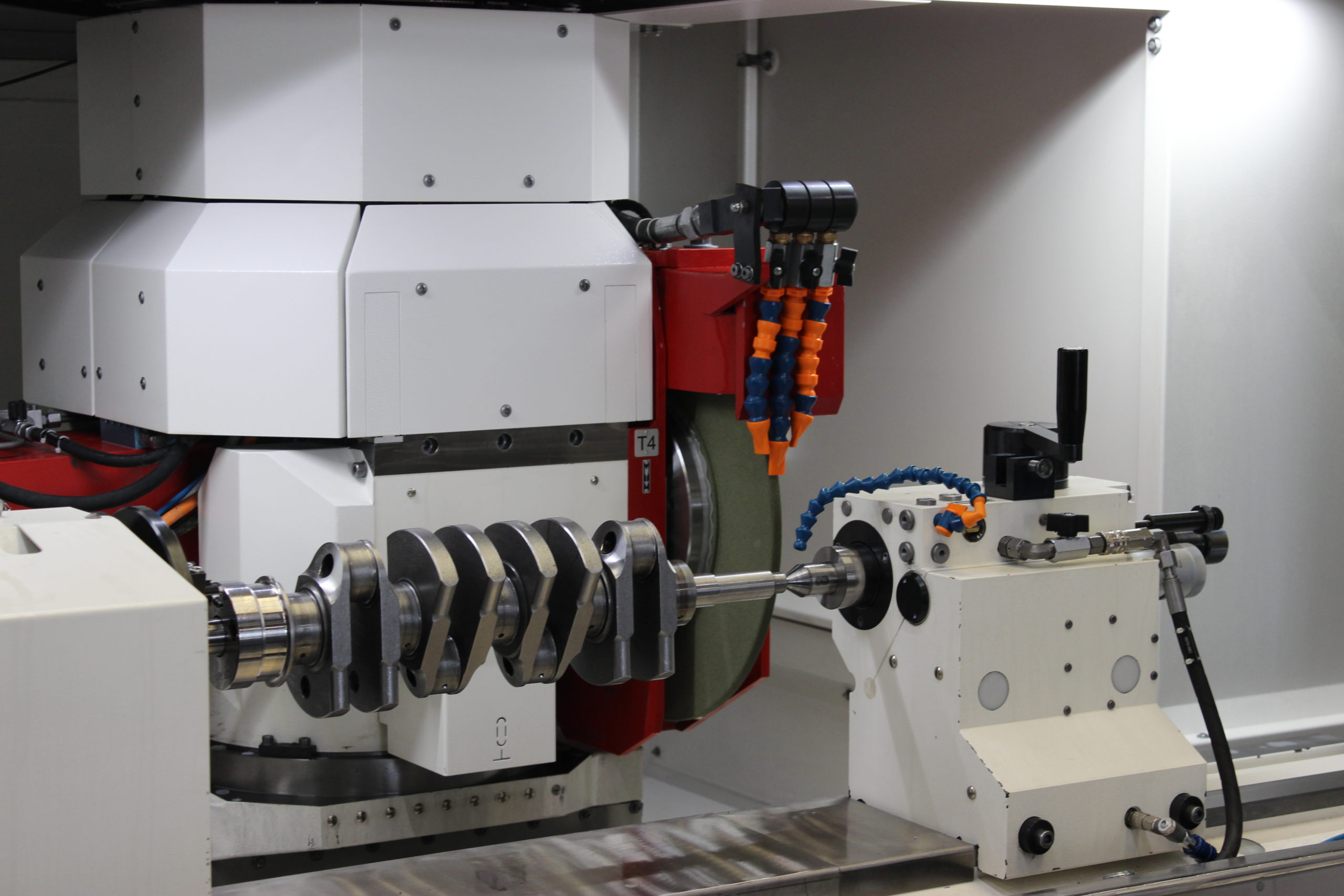

Arrow Precision manufactures OE connecting rods and crankshafts for performance production road cars as well as offering a custom service plus one-off manufacture of complete sets of rods for classic cars. It is also heavily involved in the motorsport industry, supporting customers with technical expertise, flexible manufacturing processes and fast delivery times.

Increasing demand for crankshafts prompted a search for a grinding machine that could grind crankshaft bearing journals and pins to challenging dimensions. The company reviewed several machines and the Studer S41 CNC universal grinding machine convinced Arrow that it was the solution.

Alluding to why the company invested in the Studer S41 universal grinding centre, Stuart Duncombe, the Senior Production Engineer at Arrow Precision says: “We looked for a universal CNC grinder that would be easy for the guys on the shop floor to use without too many complications. We needed the in-process gauging, repeatability and the accuracy that Studer can give us. Another reason we bought the machine is that we have a lot of work and not enough staff to get through the work on our manual machines. So, setting the Studer machine and running our larger batches through it has allowed our operators to run the Studer and continue on the manual machines. The throughput has gone through the roof since we invested in the Studer machine.”

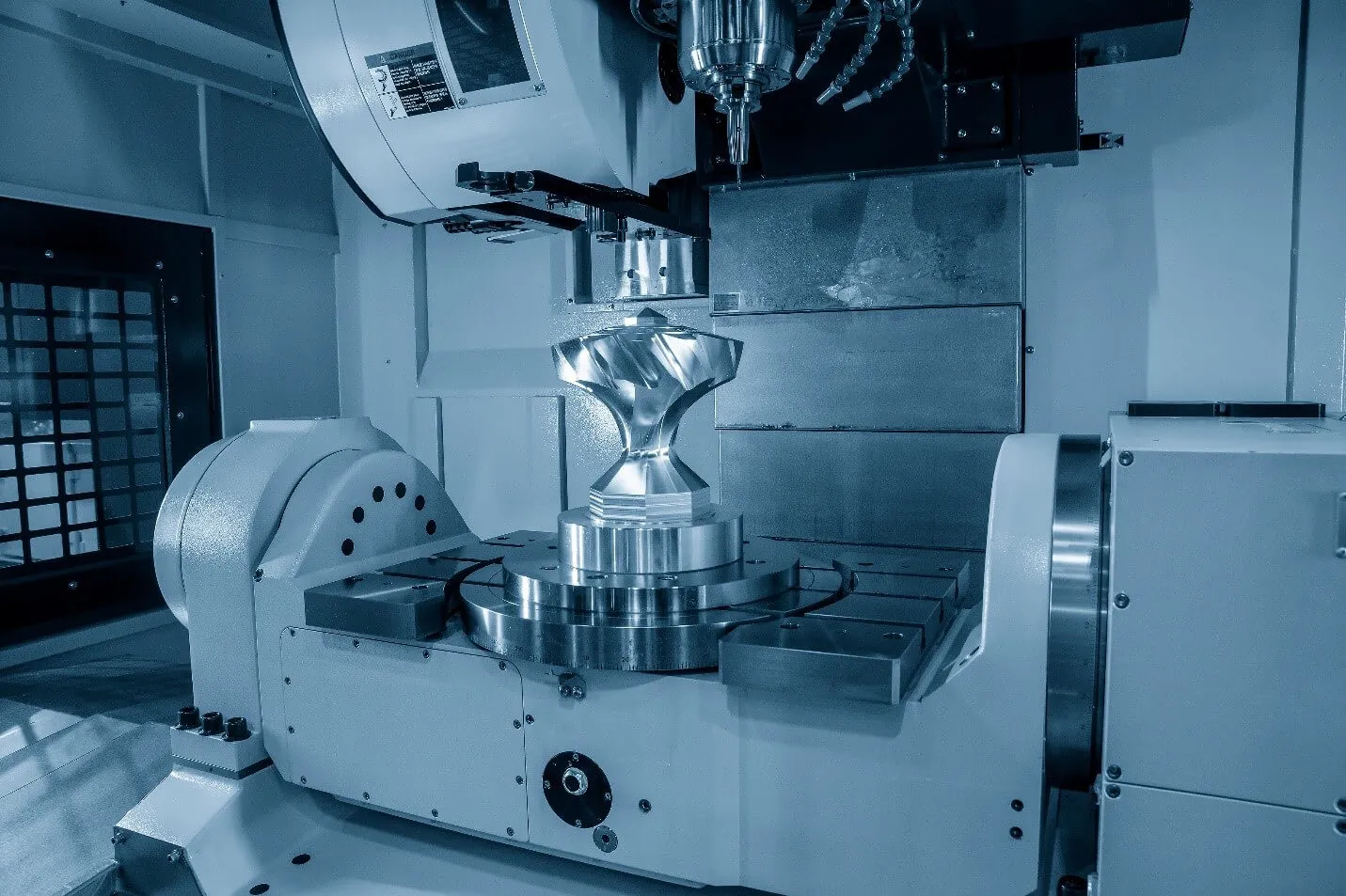

The Studer is exceeding expectations. For example, the machine can perform both external and internal operations, the S41 can also grind internal features. Crankshaft bores that used to take 30 minutes to process, now take less than 3 minutes.

“When I went over to Switzerland, Studer explained the robust Granitan® S103 mineral casting machine bed and why it is better than cast iron. The accuracy and repeatability come from the machine not having thermal expansion or contraction during different temperature fluctuations. Additionally, the guides have a hydrostatic oil film, so all axes are not touching, they are floating on oil,” continues Stuart.

The machine also has a fast dynamic B-axis and referring to the advantages of this, Stuart says: “We have a three-wheel set up to use two external wheels at any time and the machine also has an infinite B-axis. This makes the machine accurate to 5 decimal places on an angle. So, if you do a complicated 1 in 10 taper, it isn’t just 1° or 5°, it’s a 3 decimal place number.”

Alluding to the FANUC 31i Model-A CNC control system that works in synergy with the StuderWIN user interface and StuderGRIND software, Stuart says: “The StuderWIN interface is very intuitive and the conversational programming is simple. The operators can select the appropriate wheel, select the number of wheel dresses, cycles, the dressing programme – and from there it’s all pictograms. Whether you want to do a plunge grind or a traverse grind, you can easily fill in the boxes – as simple as that. The StuderWIN software is what makes the machine so easy to use.

Whilst the machine is running with G-Code in the background, it’s the intuitive StuderWIN software that is creating that G-Code. This does make the operator’s life easier.”

Comparing the Studer machine to other machine tools on-site, Stuart says: “The Studer machine has made it easier for us to not require such a highly skilled member of staff to run the machine. Other CNC grinding machines require a certain level of expertise. Since getting the Studer machine, we have four or five guys trained on how to use the machine whereas, with some of our other technology, we only have one expert on certain machines.”

“When it comes to future investment opportunities, we will certainly be looking at Studer machines, they are definitely the way to go. From day one, it has been fantastic.”