🎧Revolutionising machining efficiency with fast feed tools

In the dynamic world of machining, efficiency and precision are paramount. Most of the machining allowance is removed during rough cuts. Therefore, increasing productivity at this stage is crucial for reducing the machining costs of the entire manufacturing process. Even with improved capabilities in precise forging, die-casting, injection moulding, and other workpiece production methods that allow for obtaining a workpiece very close to the part’s final shape, a high metal removal rate during rough cutting continues to be an important factor in reducing total costs.

ISCAR has consistently pushed the boundaries to provide solutions that meet the ever-evolving demands of manufacturing. One of ISCAR’s standout innovations is the Fast Feed line of tools designed to enhance productivity while maintaining exceptional precision.

Fast Feed tools by ISCAR are designed to operate at high feed rates, significantly reducing machining time and increasing productivity. The concept hinges on the principle of shallow depth of cut combined with high feed, allowing for rapid material removal without compromising surface finish or tool life. This approach is particularly beneficial in roughing operations, where the primary goal is to remove as much material as possible in the shortest time.

ISCAR’s Fast Feed tools are engineered with advanced geometries that optimise chip evacuation and reduce cutting forces. This results in less wear and tear on both the tool and the machine, extending their lifespan. The Fast Feed tools are suitable for a wide range of materials, including steels, stainless steels, cast irons, high-temperature superalloys (HTSA), and titanium. This versatility makes the tools an attractive option for industries such as aerospace, automotive, and mould and die, where diverse materials are often encountered.

By allowing for higher feed rates, Fast Feed tools significantly reduce machining time. This efficiency results in cost savings and increased throughput, which are essential in high-volume production environments. While primarily focused on roughing, ISCAR’s Fast Feed tools are also designed to achieve suitable surface finishes, minimising the need for secondary operations and further enhancing productivity.

The combination of advanced cutting tool materials, wear-resistant coatings, and optimised geometries ensure that Fast Feed tools have a long tool life, even under the demanding conditions of high-speed machining.

Fast Feed tools are making significant impacts across various industries. In aerospace, where difficult-to-cut materials like titanium and HTSA are common, these tools help address the challenges of machining tough materials. In the automotive sector, they enable manufacturers to meet the fast-paced production demands while maintaining high quality. The mould and die industry also benefits from reduced machining times and improved surface finishes, which are crucial for producing complex shapes with high precision.

ISCAR offers a comprehensive selection of advanced cutting tools, including fast-feed turning and grooving tools. These tools are designed to enhance productivity, efficiency, and precision in various machining operations.

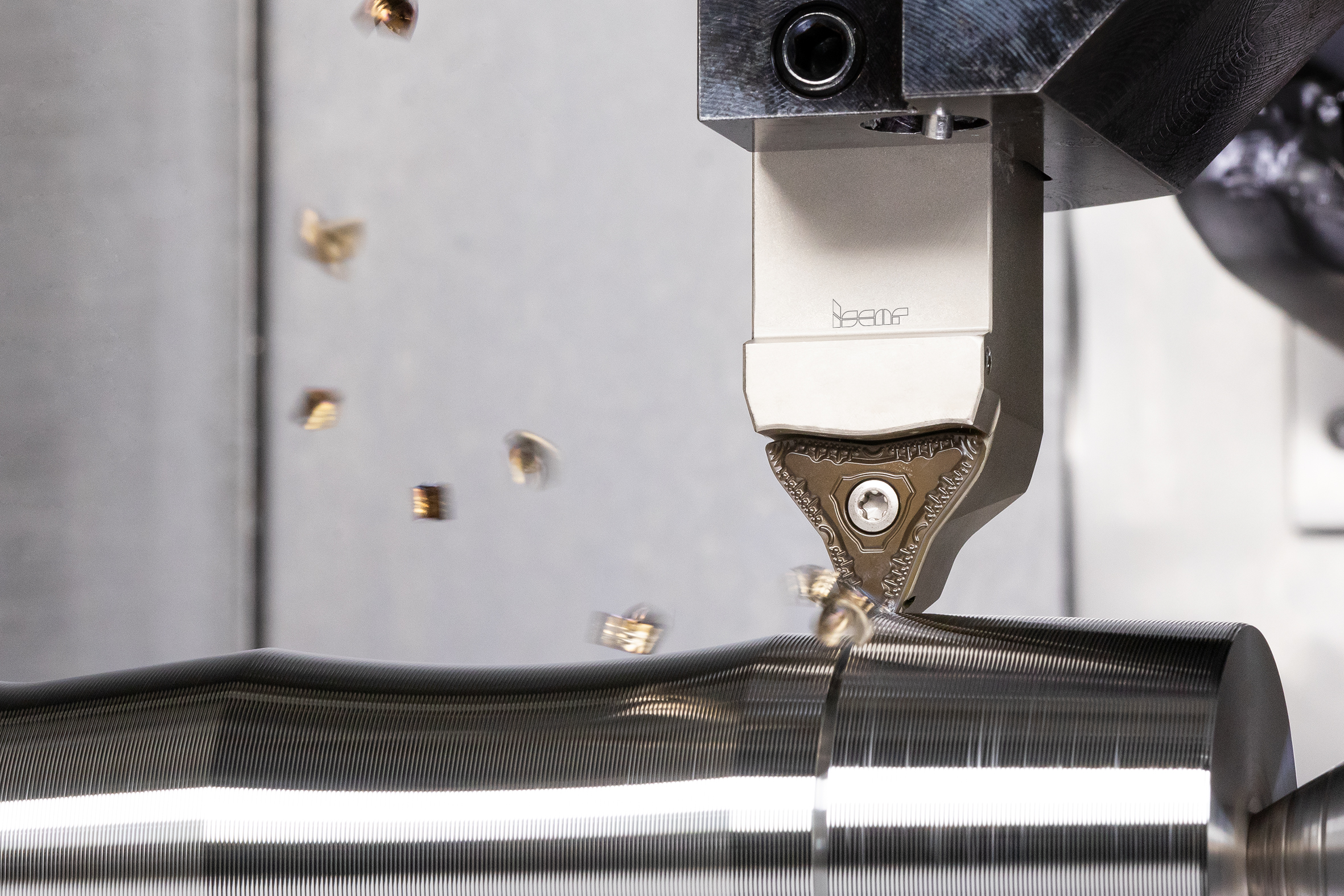

Fast Feed Turning Tools (Fig.1)

l High Feed Rates: These tools enable increased feed rates, thereby reducing machining cycle times.

l Durable Materials: Constructed from high-quality materials to withstand high-speed machining conditions.

l Precision Cutting: Engineered for accuracy, ensuring precise cuts with minimal tool wear.

l Versatility: Suitable for a variety of materials and applications, offering great flexibility.

Fast Feed Grooving and Parting Tools (Fig.2)

l High-Speed Performance: Designed to perform at high speeds, improving the overall efficiency of grooving operations.

l Reduced Cycle Times: High feed capabilities allow for quicker material removal, reducing overall cycle times.

l Enhanced Tool Life: Made from durable materials that extend the life of the tool, even under demanding conditions.

l Consistent Quality: Ensures consistent performance and high-quality results in various grooving applications.

ISCAR also provides an extensive range of fast feed milling tools designed to significantly increase efficiency and productivity. These tools are specifically engineered to deliver high material removal rates and reduce cycle times in various milling operations. Fast feed (FF) milling cutters are a key factor in high feed milling (HFM) techniques. The cutter geometry, designed for efficient chip thinning, must ensure the correct distribution of the cutting force.

There are two principal geometrical approaches. The first design requires the cutting edge of an FF milling cutter to be an arc of a circle. Another concept is based on using one or two straight edges that are chords of the arc. In both cases, the small cutting edge angle (usually 9-17°) meets the requirements of chip thinning and decreasing the total bending load on a tool.

Ensuring the geometry of solid carbide fast feed endmills and replaceable milling heads demands the specific shape of a cutting edge, while in indexable milling, it may be provided by the appropriate location of an insert of even a simple profile.

Although the introduction of innovative grades and advances in chip forming rake faces have improved progress in FF milling cutters, the essential element, the geometry, remains constant. If the cutting edge of an FF milling cutter is the arc of a circle (or the chords that approximate the arc), the cutting edge angle of the cutter is not a constant value but varies depending on the axial depth of cut from 0 to the mentioned 9-17°. In milling, the chip thickness is a function of the tool’s cutting edge angle. Under the same conditions, the smaller the cutting edge angle, the thinner the chip. Therefore, the programmed feed should be increased correspondingly to produce chips of the required thickness.

Features of ISCAR Fast Feed Milling Tools (fig.3)

l High Feed Rates: These tools are designed to operate at high feed rates, allowing for faster machining processes and reduced cycle times.

l Durable Structure: Made from high-quality materials that ensure durability and long tool life, even under demanding conditions.

l Precision and Stability: It is engineered to provide precise and stable cuts, minimise tool wear, and improve the quality of the finished product.

l Versatile Applications: It is suitable for a wide range of materials and applications and offers great flexibility in use.

l Innovative Design: It incorporates advanced geometries and coatings to enhance performance and chip evacuation, reduce heat generation, and increase tool life.

Popular Product Families

l HELI-6-FEED: Known for its double-sided indexable inserts, offering high feed rates and excellent performance in various milling applications.

l NEOFEED: Specifically designed for high feed milling, these tools carry cost-beneficial double-sided square inserts with 8 indexable cutting edges, providing outstanding material removal rates.

l MULTI-MASTER: This modular system with interchangeable heads allows for quick and easy tool changes, enhancing productivity and reducing downtime.

ISCAR’s Fast Feed tools exemplify the company’s commitment to providing innovative solutions that address the real-world challenges faced by manufacturers. ISCAR’s Fast Feed tools are a testament to the company’s forward-thinking approach and dedication to enhancing machining efficiency. As industries continue to demand faster, more precise, and cost-effective solutions, ISCAR’s innovations in fast feed technology are set to play a pivotal role in shaping the future of manufacturing.