Renishaw ready for industrial automation

The industry is facing challenges from all directions and one key challenge manufacturers are striving to overcome is the lack of skilled engineers. On a recent visit to Renishaw plc, MTDCNC spoke to Leigh Turnbull to find out what the measurement and additive manufacturing business is doing.

When MTD last spoke with Leigh Turnbull, he had significant concerns over the skills shortage in the industry. Revisiting this issue, Leigh from Renishaw tells MTDCNC: “It’s no secret that within the manufacturing fraternity there is a big skills gap and that is one of the areas that is giving rise in business to Renishaw. Clearly, as there is a lack of skilled machine operators and measurement operatives, this is persuading companies to automate as much as possible. This falls straight into the ‘sweet spot’ of Renishaw’s portfolio.”

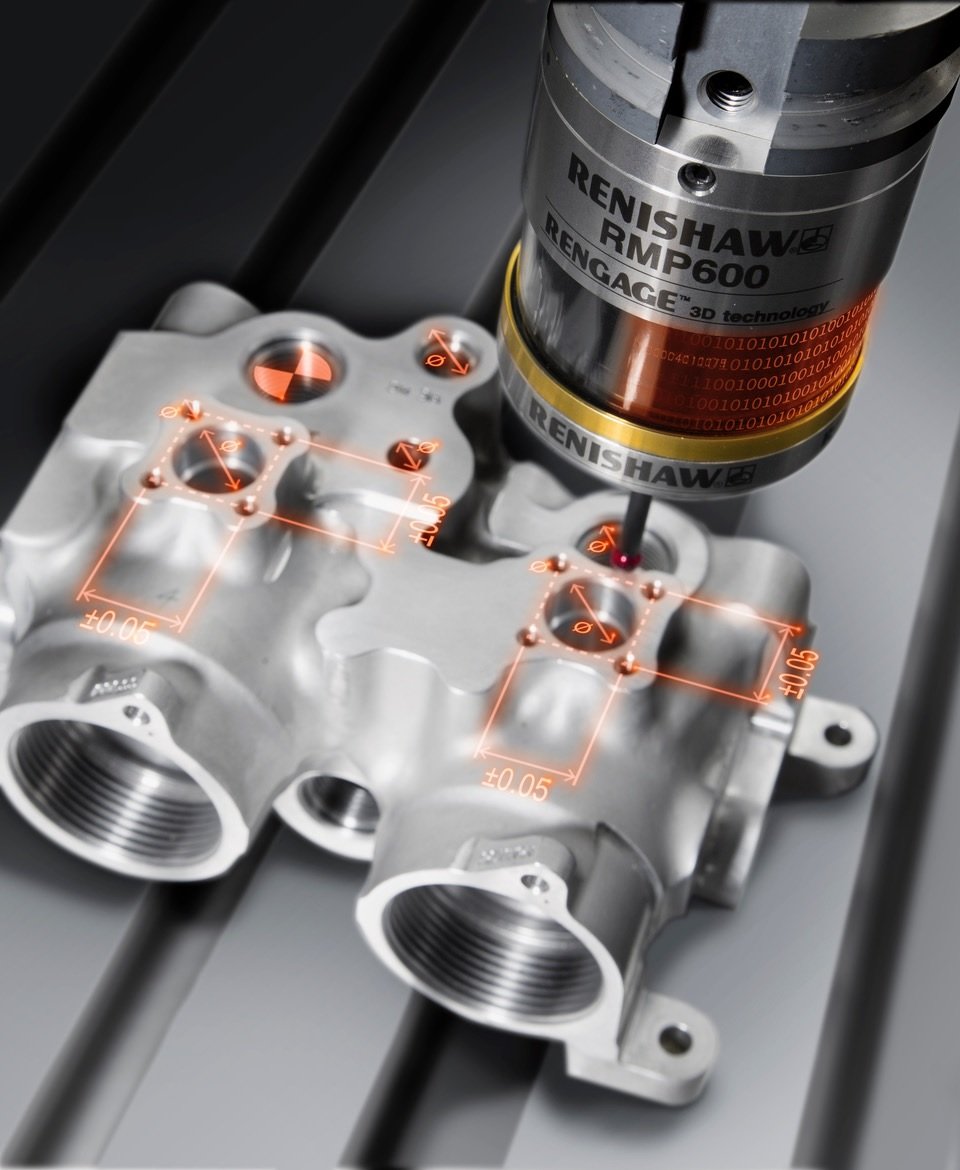

“Given our suite of industrial metrology products and Industry 4.0 initiatives; companies have a desire to reduce tack time, increase CPK and reduce scrap and rework to become more profitable. All these factors give rise to opportunities where we can influence the output and bottom-line profit.”

Referring to partnerships with customers, Leigh continues: “Partnerships are critical to our business. Across the globe, we have subsidiary networks where we have sales managers deployed to cultivate and look after relationships. Key in every single instance is that we take our relationship with that customer from a transactional point of view to becoming a trusted adviser. This is where customers really rely on Renishaw, we aid them with solutions and give advice.”

“We actively relay things back from the marketplace to our product divisions deployed within industry. So, where there are problems, we will always find a solution. As a company, Renishaw is built on IP generation and patent’s and we will continue to do that in earnest moving forward. From our headquarters, we can offer the marketplace reassurance that you are in safe hands. When you come around our facility and look at our demo area, whether it is the machine-tool area, the CMM area or the additive department; the people that you talk to here will give you the satisfaction that we have probably done it before and we have probably provided solutions for similar customers in similar situations. It is that reassurance that we are tried and tested that gives engineers the confidence to work with us.”

Concluding on the subject of automation and Industry 4.0, Leigh says: “We have products across our industrial metrology portfolio that can meet automation and Industry 4.0 in all areas. The more that automation is required, the more that manufacturers will be reliant on companies like Renishaw and our product portfolio.”