Kanyana delivers exceptional service

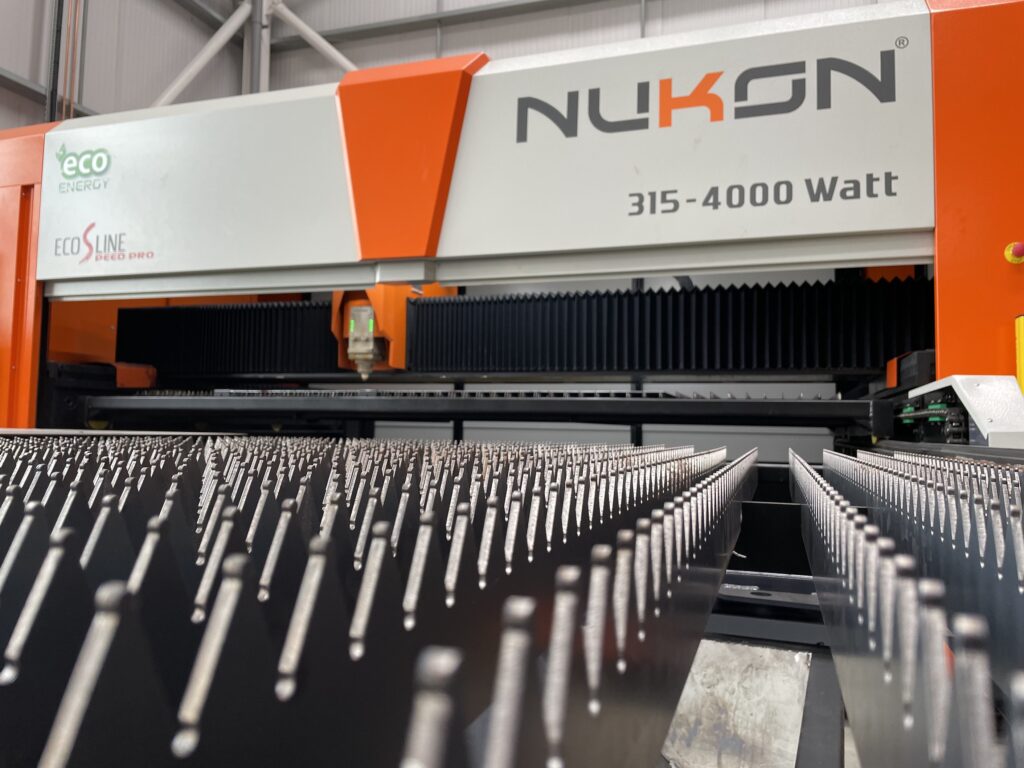

Kanyana Engineering has followed a policy of providing sheet metal services at its Greenfields, Western Australia manufacturing facility since its formation in 1997. Graham Dawe, Managing Director says: “We started this process with a 100-ton press capable of bending 6mm material when our competitors could only bend 3mm material.”

This policy is continuing and now the company has progressed from high tolerance plasma cutting to fibre laser cutting with a 15kW 1.5 by 3m Bystronic Bystar and the first Bystronic 20kW Penta laser with 2.5 by 6m bed in Western Australia. This machine can cut 50mm mild steel, stainless steel and aluminium, giving the company the largest job shop capacity in the region. The capabilities of the company make it sought after for supplying civil, mining, industrial, construction and creative arts projects. The variety is huge and includes balustrades for the Kalbarri Skywalk which soars 100m above the Murchison River Gorge and mining refuge chambers which are designed to protect miners in an emergency.

As part of its pursuit of excellence, it understood that software and the integration of the company’s systems were crucial to its plan. “I had experience from a previous computer business and wanted a fully integrated CAD/CAM and ERP system. With Lantek, this was all possible and we went for the full suite of Lantek Expert, Flex 3D and Integra. We can take DXF files and 3D models directly from the customer and use the system to nest parts, program the lasers and calculate a consistent and accurate price for the job, irrespective of who creates the quotation, offering our best price in a matter of a few minutes.”

Stock material is stored within the system as are remnants from previous jobs so the company knows what is available, what has been earmarked for a job, and what needs to be ordered and can trace the material down to the individual sheet used by its tracking number to produce material certificates for the customer.

Once a quotation becomes an order, all the details and history of the job are released to the workshop ready for manufacture. Lantek’s MES software keeps control of where parts are in the shop, the time taken for each operation and any lost or damaged parts which need to be remanufactured. The live information is collected via workshop PCs and iPads on the laser machines, the press brakes and in the six fabrication bays, where the operators log in to record and validate what is happening and the state of each part running through the factory, even subcontracted operations and bought in items are tracked. Graham Dawe adds, “We have put in two extra processes, quality control and pack and dispatch. These are a final check, allowing us to find and remedy any faults, control the status of the customer, for example, any credit limits, prepare delivery documentation and material certificates, create the invoice, and finally share the information with our Xero accounting software.”

Lantek’s Integra Sales Module helps Kanyana see where its orders are coming from, showing sales by staff member or by customer enabling it to analyse which quotations are working best. It also uses information about capacity in the workshop to provide realistic delivery times and looks through material stores to find how much extra material may need to be ordered. “We aim for a 3-day lead time if possible. We run a 1½ shift system which is 12-14 hours per day, so we can increase this to double shift if we need to create more capacity. With our exact knowledge of production capacity in the factory and automation on the lasers we get much higher beam-on times than most manufacturers can achieve. Similarly, with Lantek MES Manager we can always answer the customer’s questions about where their part is just by looking at the system, keeping them in the loop for realistic and accurate delivery dates even though we have thousands of parts going through the workshop at any one time.”

Kanyana installed the Lantek software in 2019 during Covid so all the training and installation was online. Graham Dawe says: “Now that we have had the system for a few years we get the full benefit and, if Lantek tells us that a job will take 5 days, we know that this is accurate as are the costs involved. This means that we can alter our quoting style where necessary to get valuable or prestigious projects. Overall, the integration and accuracy of the system is the key to our success, enabling us to be highly responsive and competitive, achieving much more with considerably fewer people than our competitors.”

Laser Radar aligns with new automotive VDA standards

Laser Radar aligns with new automotive VDA standards

As a subsidiary of the Nikon Corporation, Nikon Metrology has welcomed the recent comprehensive update to Volume 5.1 of the automotive measurement standards issued by the German Association of the Automotive Industry (VDA). The newly updated VDA standards cover a more comprehensive array of measurement applications within the automotive sector, addressing the industry’s growing demand for more diverse and sophisticated metrology solutions.

As Andreas Fuchs, Application Engineer at Nikon Metrology explains: “We already offer innovative, traceable measurement solutions based on national and international standards for the automotive industry. The new standard defines very precisely the procedures for evaluating the precise technology that we provide. After all, with the APDIS Laser Radar, our portfolio has featured a product for some time now that can also deliver traceable inline measurements as described in VDA Volume 5.1. Incidentally, those who use this technology no longer need a dedicated measuring room for a fixed CMM – enabling them to save a great deal of money, time and space.”

The APDIS Laser Radar represents a USP with its proven ability to measure details at a distance without needing handheld probes, targets or surface preparation. This makes it ideal for automating repetitive inspection tasks with high accuracy. The system covers many manufacturing, industrial and research applications, including those that involve hard-to-reach features and are complex, delicate, or labour-intensive.

The additional benefits of the APDIS Laser Radar include fast and accurate automated measurements with minimal set-up time for maximum productivity with flexible and portable installation. This allows for the absolute and accurate measurement of parts during production or wherever required, including directly on the production line. The APDIS Laser Radar, in particular, displays its strengths in the automotive industry. For example, the system can measure automotive features with absolute accuracy at high speed with no part preparation, whether inline or offline.

With inline measurement, data can be collected in a much larger sample, resulting in a much more extensive data volume for process control. Therefore, it is wise to develop and use smart evaluation methods or systems and, in the process, adapt the reaction speed to the increased data volume.

“These days, inline measuring technology tends to measure 100% of the parts, giving a very dense test sample with an extremely short response time and close to production,” says Fuchs. “When the part goes through, a real-time statement regarding the quality of the part is delivered immediately – meaning the response time, as well as statistical and general process control, are far better than before. A measuring room, on the other hand, only provides information about ongoing quality with a delay. In addition, there are no statements about the ongoing process, and production continues.”

VDA Volume 5.1 appears to consider the trend that measurements are increasingly being made using traceable inline measuring systems instead of offline in the measuring room, making the implementation of suitability certificates for inline measuring processes in accordance with VDA Volume 5 more critical. VDA Volume 5.1 introduces an eight-stage model for evaluating inline measuring systems throughout their lifecycle. This model generates suitability certificates crucial for system release, ensuring compliance with automotive manufacturing standards. These certificates are significant in procurement as tenders for measuring systems regularly reference VDA volumes, highlighting the importance of standards in guiding industry-wide quality control and measurement practices.

‘The Beast’ devours everything placed before it

‘The Beast’ devours everything placed before it

Many subcontract manufacturers have the challenge of knowing which machines to purchase to suit the diversity of work that comes through the door. For other businesses, it’s development and growth that dictate the purchasing decisions. For Ian Gibson, Managing Director of Vision Precision Engineering, the latter scenario led to investments in XYZ machine tools. Starting the business with his uncle, Dennis, they set about finding work – a significant challenge.

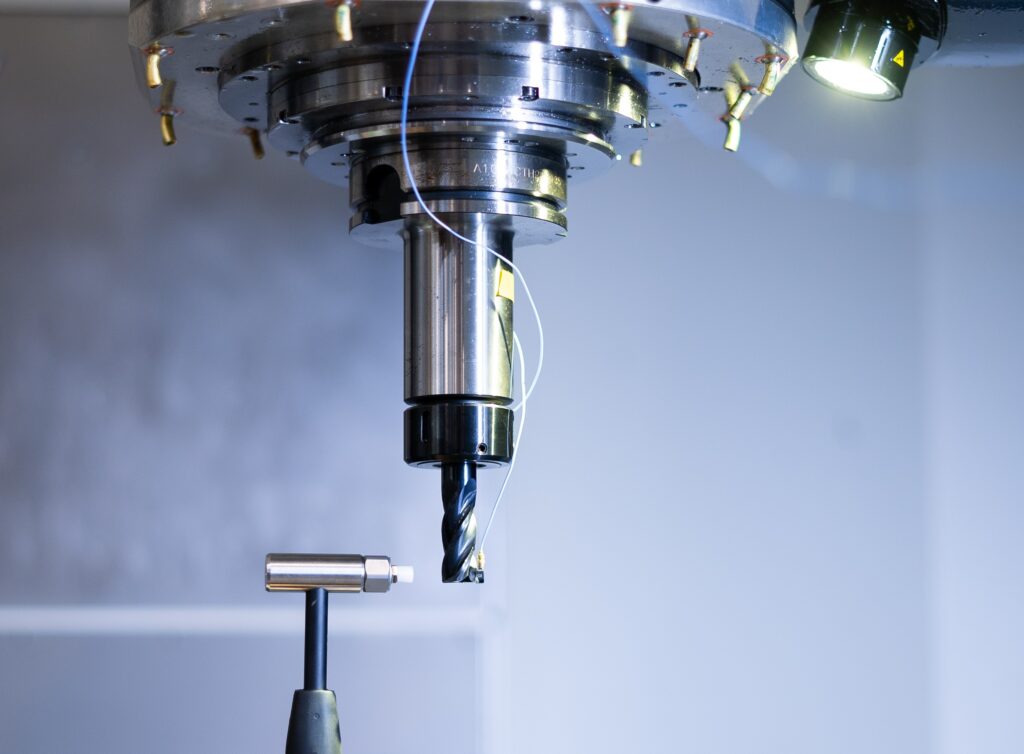

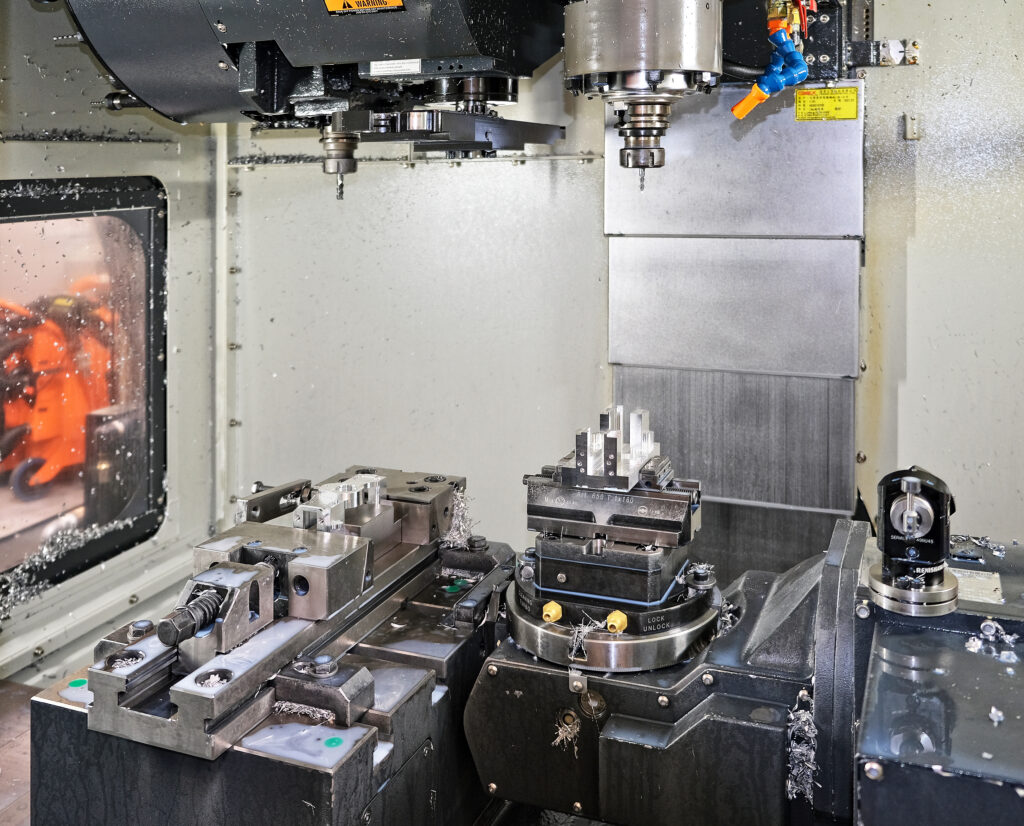

Using existing contacts, they found an unlikely source of work making parts for coffee machines in Costa Coffee stores. “We were approached to make improvements to the in-store machines so that the baristas could not make mistakes in loading the cleaning products used in the machines,” says Mr. Gibson. This influx of work prompted the business to seek improvements in their manufacturing processes, leading them to XYZ for a solution to make parts faster than on their traditional milling machine. Mr Gibson continues: “Steve Cox, the XYZ Area Salesman regularly called in and, when the company needed to invest in new equipment, he helped select the right machine which was an XYZ 710 vertical machining centre complete with a 4th axis.”

This investment created a new dilemma as making parts faster created a bottleneck in the secondary operations. This led to further investment in a smaller machining centre from XYZ to handle the increase in demand.

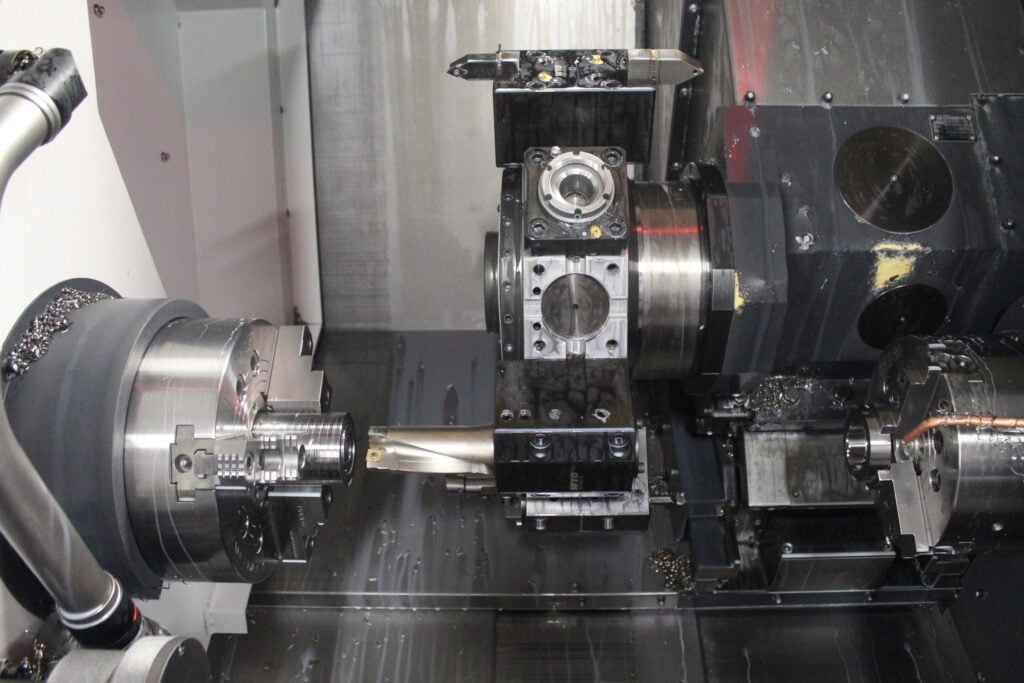

“Even with two machines and 4th axis fitted to the mill, we were still falling behind in supplying parts to our customers so again we contacted XYZ to see how we could improve our manufacturing further,” comments Mr. Gibson. The answer was to invest in an XYZ TC 320 LTY-driven tool lathe. “The ability to produce milled and drilled features on our turned parts was taking up capacity on the original mill, so it made sense to purchase a machine that could produce our parts in one hit which is why we decided to invest in the TC 320 LTY.”

With the hardened box way-built machine with its Y and C-axis, along with driven tool capability in place, Vision Precision set about getting the most out of its latest purchase. “Now we have this machine available to us, we have been able to quote for work that previously we could not tackle,” observes Mr Gibson. This is partly due to the maximum turning diameter of 320mm and the maximum turning length of 550mm. With a bar capacity of 78mm, it also means that Vision can produce more parts from bar rather than billets, and with a barfeed purchased for the machine, lights-out machining has now become a regular occurrence.

“The machine just seems to tackle everything we throw at it.” Mr. Gibson states. “Big or small, it does it all, and the material removal rates are phenomenal on jobs from 20mm depths of cut when turning to drilling a 70mm diameter hole with a modular drill in super duplex material. When you consider we were only running at 200rpm when performing the drilling and it was only using 25% of the available spindle power it’s a well-built machine with great power and it holds the tolerances we demand of it all day, every day”.

Mr. Gibson also notes: “It’s not only the machine that’s important to me but the whole package. From sales through to the installation, training and ongoing support from XYZ’, the whole experience has been second to none and that’s why I also purchased a CT65 HD.”

By posting about its work on social media, Vision has generated interest from companies looking to outsource jobs. Business is growing, which has led to a recent move to new premises. From modifications to coffee machines, Vision is attracting work from various sectors from green energy to defence.

Innovation fit for a King

Innovation fit for a King

In AML’s digitally enabled ‘war room’ the firm’s co-founder and Managing Director, Gareth Morgan, is discussing the good news with his colleagues: the 100-strong precision engineering team has just won the coveted King’s Award for Enterprise Innovation. The award recognises ‘leaders in their field who adopt exemplary working practices and inspire other businesses.’ It’s one of the UK’s highest accolades for business excellence.

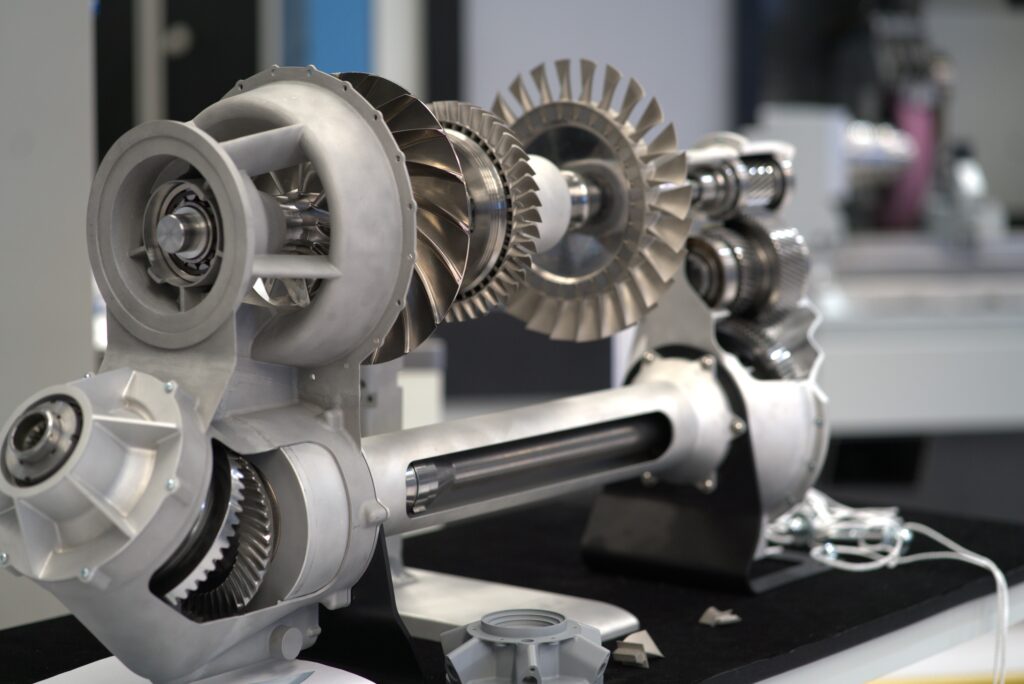

Fittingly for an MTD aerospace issue, the award is in recognition of AML’s ability to apply technologies and lean processes more often seen in the automotive sector to unlock a staggering two-fold productivity increase in the aerospace sector: enabling a leading UK jet engine manufacturer to expand into the lucrative business aircraft market which is expected to grow to $36.4bn by 2030.

“We are all so proud of what we have achieved and that our skills and talents are recognised at the highest level. It sends a powerful message to our customers that we are constantly seeking better and smarter ways of delivering products to three sectors that are critical to the success of UK Plc – energy, aerospace and defence,” says Gareth, who established the company as a spinout from the Advanced Manufacturing Research Centre (AMRC)16 years ago.

The engines for this market require many novel design elements, materials and technologies to achieve the necessary performance levels demanded by manufacturers, regulators and governments. But behind every challenge, lies an opportunity.

“This combination of high demand and high technological requirements for an existing customer presented an opportunity for AML to develop a new aerofoil manufacturing process that meets the stringent demands of the next generation of business aircraft engines. This opportunity drove the subsequent R&D to develop this innovation project,” Gareth said.

“Our success in delivering this innovation has accelerated our growth by creating eight new roles – six machine operators and two manufacturing engineers – supporting the new robotic production cell built to manufacture these components. Several employees working on the cell have been trained to program and operate it, extending their knowledge and experience,” says Gareth, proving that robotics can increase the demand for skilled roles, rather than remove them.

Gareth acknowledges the role that others have played in helping the embryonic AML go from two co-founders and £90,000 turnover in 2008, to a 100-plus workforce and a turnover of £11m and growing today.

In the case of the King’s Award, he pays special tribute to the Aerospace Technology Institute (ATI) which, over the last decade, has invested £3.6bn in UK manufacturing in “a long-term plan to produce more than 400 cutting-edge aerospace R&D projects across the UK, driving world-class research in sustainable aviation and supporting thousands of jobs”.

Funding from the ATI for the Automotive Excellence in Aerospace (AXIS) project, along with R&D support from former colleagues at the nearby AMRC were critical in giving Gareth and his team the financial and technical support they needed to turn this challenge into an opportunity.

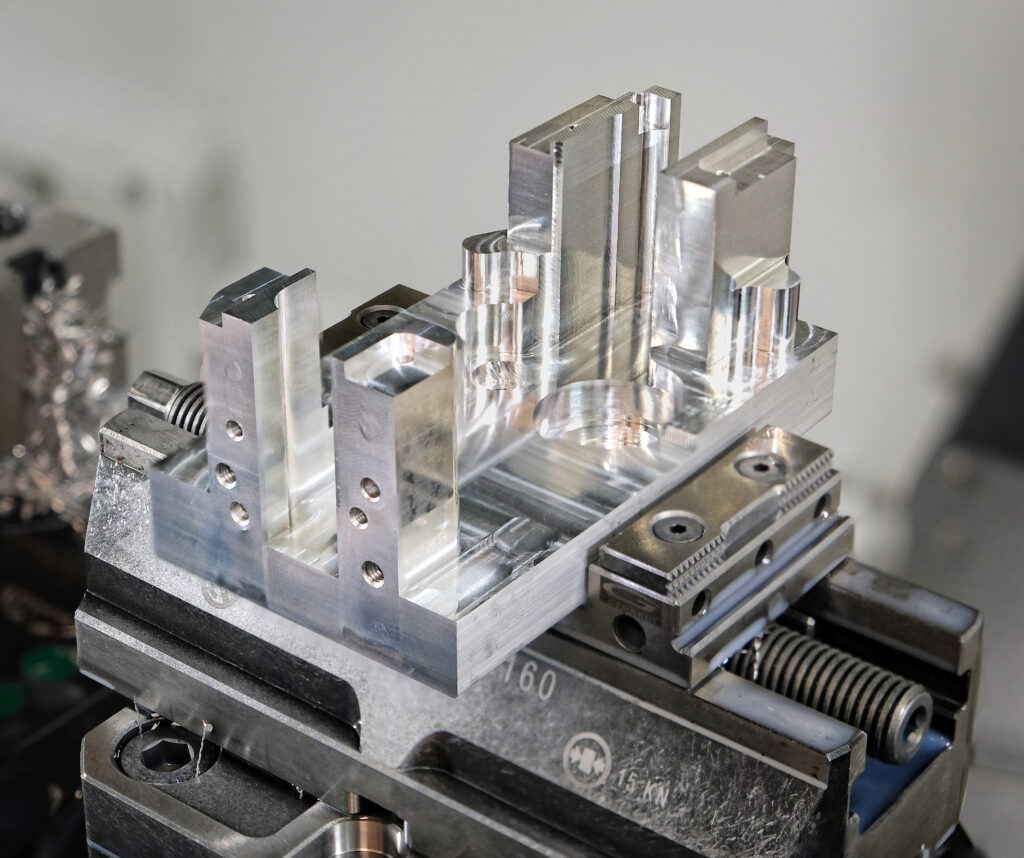

As with all innovations, this required a venture into the unknown. For AML it meant the adaptation and deployment of robotics using advanced automation simulation tools. It also required the development of a bespoke clamping design, which illustrates the value of having a world-leading R&D partner on your doorstep in the shape of the AMRC’s automation experts in Factory 2050.

“Working with the AMRC gave us the confidence to be bold as they have R&D strengths in both precision machining and robotics in the aerospace sector. Having such talent on the doorstep gives us a huge advantage as a business,” said Gareth.

It is also a reason why South Yorkshire is consolidating its reputation as global player in the aerospace, energy and defence sectors, which was recognised as it is the first Investment Zone in England with a focus on advanced manufacturing. This has been accompanied by an announcement that ATI is investing close to £30m in the AMRC-led COMPASS project to accelerate composite aerostructures with Boeing and Spirit AeroSystems.

For Gareth, the big message to government is that ATI’s long-term strategic R&D funding is key to expanding what UK aerospace OEMs and their supply chains can achieve when manufacturers have a public sector partner with a consistent vision for the sector and the financial firepower to fund innovation projects.

These investments, all match funded by the private sector, are essential to maintaining the UK aerospace industry’s position with a staggering 70% of domestic aerospace production being exported around the world.

As thousands gather for the Farnborough Air Show it is also worth reflecting that the sector directly employs 108,000 people and supports over 5,200 apprenticeships across the UK: delivering high-value jobs for a highly skilled workforce. The UK exports £18.6bn with a turnover of £27bn last year.

AML, and innovative supply chain firms like them, are key to the UK retaining its position as a leading player in this global market. But they are also key to driving inclusive economic growth in the regions and nations of the UK. The success of firms like AML shows that regions don’t need a major OEM to drive innovation and growth.

“You don’t need to produce or innovate the complete product to unlock a significant profit share of the final sale. It’s the same in tech. Ask HP or Dell whether it is them or Samsung and Intel who enjoy the best profit margins when a consumer buys Dell or HP computers?” Gareth said.

AML is now a digitally driven tech business. Cloud-based data analytics informs everything they do. But getting there required support. For Gareth, this meant engaging with what he describes as the ‘brilliant Sharing in Growth programme’ whose vision is ‘growing great businesses, by developing great people, for this generation and the next.’

“Our war room is the result of that collaboration giving us the manufacturing equivalent of the Starship Enterprise flight deck. No more Monday morning mayhem where people spend hours sifting through data, turning it into graphs and charts. It’s all there in real-time dashboards, freeing us to interpret the data and make much better, informed decisions.”

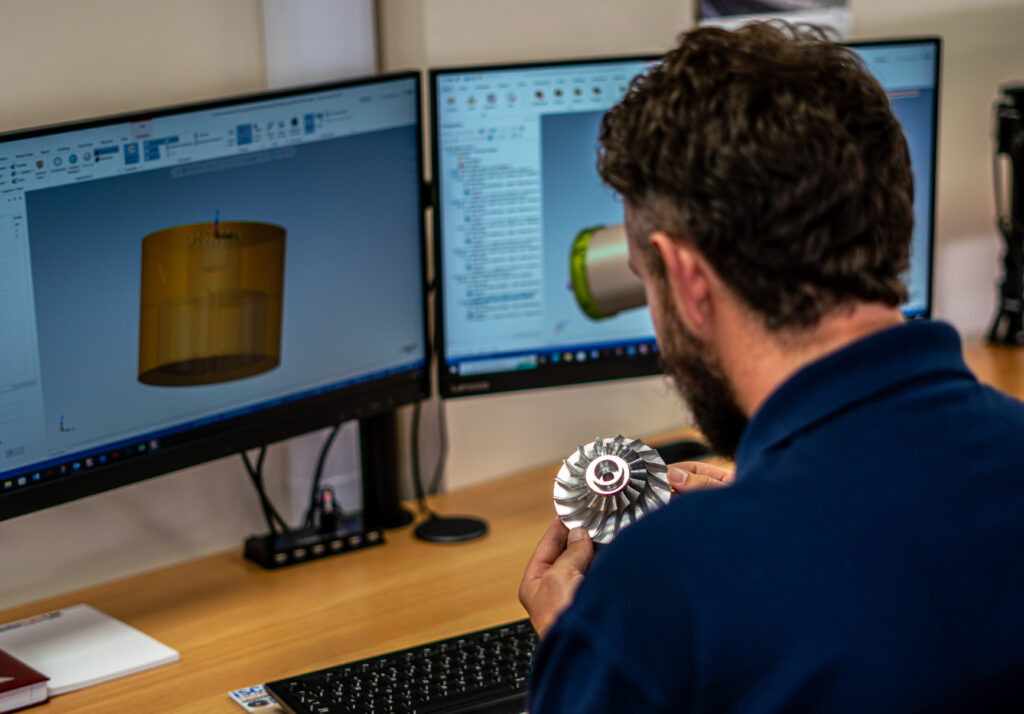

But digital is not confined to the war room, it runs like a thread through the whole business: from its extensive quality management system to its adaptive machining algorithms that enable AML to achieve the tightest of tolerances across a range of materials from titanium and nickel-based superalloys, to softer alloys such as aluminium.

For the King’s Award-winning project AML developed bespoke algorithms to generate efficiencies and ensure that each component’s features perfectly blend with the other components’ surfaces, increasing manufacturing performance and reducing rejected parts.

But not every innovation is entirely high-tech. As part of the ATI-funded project, AML looked to the centuries’ old manufacturing technology of forging to deliver big savings in time, energy and cost. This required collaboration between Redditch-based forging specialists, Mettis Aerospace, the AMRC and AML to overcome many hurdles, making this a fully integrated manufacturing process that provided consistency throughout the whole manufacturing chain.

The lesson from this for policymakers and manufacturers is the need to identify niche capabilities in fragmented global production supply chains that open up new markets and products. But broad economic surveys of regions and sectors alone will not reveal where these gaps and opportunities can be found – that requires real manufacturing intelligence-gathering activity.

As AML’s success demonstrates, innovation can have a major impact on productivity. And productivity, which has flatlined in the UK since the 2008 financial crash, is what drives wealth creation, economic growth and personal prosperity.

Back in the war room, Gareth reflects on the importance of being part of the bigger advanced manufacturing cluster or innovation district taking shape in South Yorkshire. For him, it puts fast-growing companies like AML on the global stage. As Gareth says: “AML doesn’t win it on its own, it wins it by being an integral part of this growing advanced manufacturing cluster. If you’re going to compete globally, then you have to be part of a bigger team. When we are successful that means a win for AML is a win for South Yorkshire and a win for UK plc.”

Guhring ‘powers-up’ productivity for EVs

Guhring ‘powers-up’ productivity for EVs

As a machine tool builder that manufactures high-end machines for the global market, Heller UK is frequently involved in turnkey projects for prestigious OEMs. On a recent project, the Redditch company enlisted the support of the cutting tool experts at Guhring.

There has been a wide spectrum of tools used on this project for a leading manufacturer of Electric Vehicles (EVs), including the Guhring tool holders and tool vending technology. As part of the package to accompany the cutting tools, the EV manufacturer has selected a vast range of standard shrink chucks, hydraulic chucks and synchro-tapping chucks.

The cutting tools incorporated in this project included a huge range of standard products, all carefully selected and tested to minimise cycle times while achieving tight tolerances. Whilst the standard range of Guhring products accounted for a significant element of the system integration project, it was the bespoke PCD combination tools that demonstrated Guhring UK’s expertise as a one-stop solution provider.

With the PCD combination tools manufactured at Guhring UK and Guhring Germany, the bespoke solutions were developed to achieve ‘one shot’ plunging. The bespoke tooling aimed to reduce cycle times and adhere to the high surface finishes required – and maintain this over the life of the tool.

Discussing the project, Guhring UK’s National Sales Manager Chris Bush says: “It is a project and industry that is at the very forefront of technology. The end user typically specifies a machine builder and cutting tool supplier – in this instance, it was Heller and Guhring for the cutting tools.”

Looking at how the process delivers a solution for the customer, Chris continues: “In Germany, we have a large project engineering team with over 200 employees. So, when we receive a CAD model of the customers’ component and the machine capabilities, we can develop the cutting tools and machining strategy from that and create an optimised solution in conjunction with Heller.”

“This requires several meetings to discuss the machining strategies and how we develop the tooling to create a seamless solution from machine tool to cutting tool. At Guhring, we supply everything from toolholder to the cutting-edge and that also entails all the speeds, feeds and cutting strategies in conjunction with the machine builder. Once we supply all the cutting data and tooling sheets, we will then visit Heller and do all the initial run-offs to ensure all the cutting data is optimised and the machining strategy is working well.”

Alluding to the overall project, Chris adds: “It has been a great partnership between Guhring and Heller and the current EV project is the biggest project we have collaborated on in the UK.”

Discussing the project from a Heller perspective, Tad Forys from Heller Machine Tools UK says: “We delivered 22 machines in this project. That includes eleven 5-axis machines and 11 4-axis machines – all built in the UK. With this project, we have gone from a customer drawing to a fully automated production line. From the initial enquiry with the customer, our engineers here in the UK conducted comprehensive cycle time studies. Following on from that, we developed custom hydraulic fixtures to hold the parts; and we have used these fixtures because it is a high-volume electric vehicle application.”

“This recent project that we collaborated on with Guhring has been a perfect demonstration of team work. When we talk about collaboration, it isn’t just about working together – it’s about aligning our values and expertise. The first two machines for the production line are here at Heller, so we can do the initial production ‘prove off’ before the machines land on the customers’ shop floor. Guhring has been with us for every step of the journey, clocking in tools, optimising speeds and feeds to make sure we have the most efficient process for the customer before the machines are delivered.”

“From a Heller perspective, this project has been an outstanding success. Our end user is very happy. Everything has been delivered on time to a particularly demanding customer – and this has been made possible by a close working partnership with Guhring who have helped us every step of the way,” adds Tad.

Discussing the tooling solution further, Guhring’s Chris Bush adds: “Even though we are supplying the tools and tool holding for this project, we are also supplying the tool management vending solution. As this is a significant project with a large number of tools, we are supplying the vending machine with some add-on units. The proprietary software that Guhring programs and supplies with this can also be linked to the customer’s ERP system. This provides complete synergy and automation for the end user from tool ordering with complete transparency of costing and cost centres by the operation, the individual machine and even by the operator. This system provides unparalleled transparency, so everyone can see the costs and where the costs are going.”

“From a Guhring point of view, this project has been a great success and working together with Heller has been a true partnership, and a fantastic example of delivering a proven process to the customer on time,” concludes Chris Bush.

Zero Point clamping systems from LANG

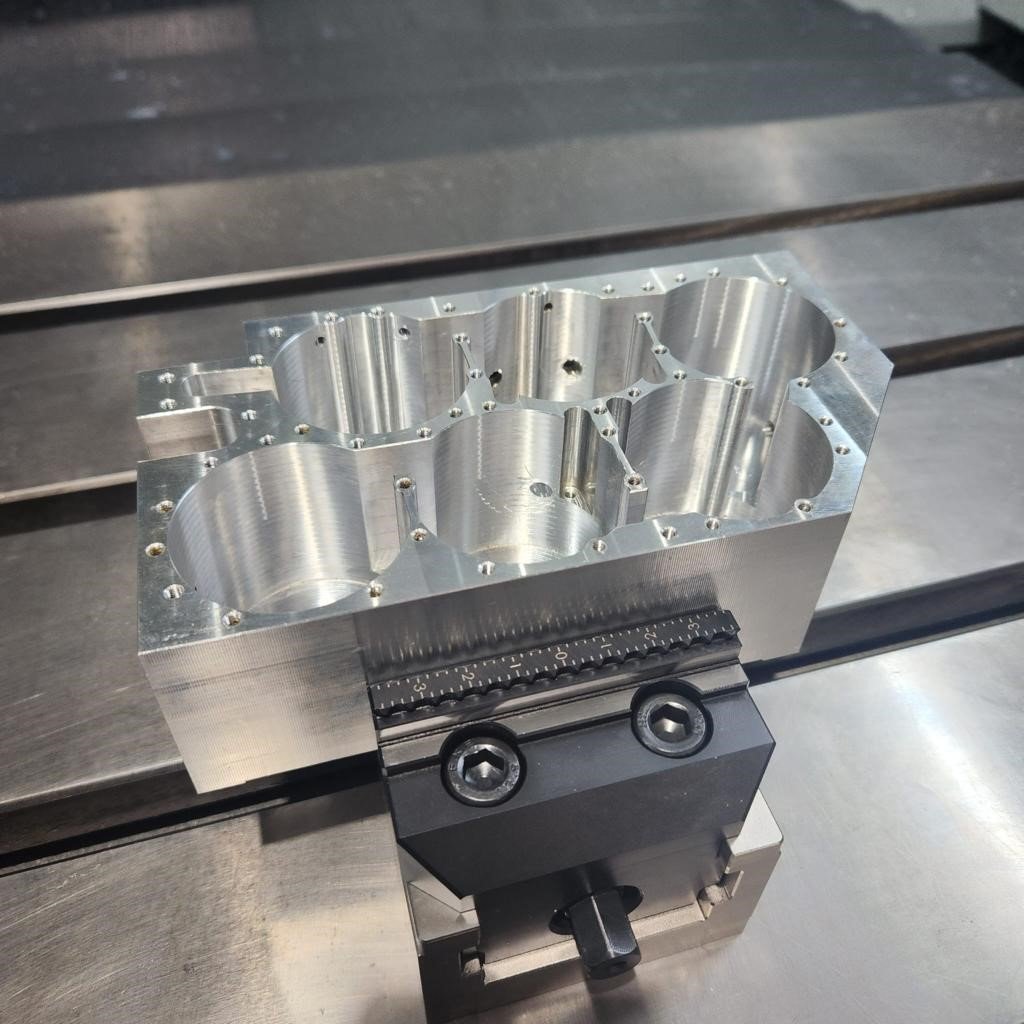

There are many quick-clamping systems and that’s good because every machinist’s day-to-day work is different. They all have a common machining job that follows the process of either turning, milling, grinding or a hybrid combination of these tasks.

Once the job or a machining sequence is finished, changeovers take place and everything starts again from the beginning. The most important task of a clamping system is to lock the part in place to handle the machining forces in the turning or milling process. The clamping system must match the component geometry and the machining process. Typical shapes for components in an industrial environment are cuboids, cubes, prisms, pyramids, cones, spheres and cylinders. If workpieces are manufactured individually or in series, part quality is assured by using a zero-point clamping system. This ensures the necessary accuracy and repeatability of the machining processes using a pre-defined reference point. Choosing the right clamping device has a significant impact on the efficiency of the machining process, as the machine can be set up more quickly.

Zero-point isn’t always the best direction

However, the potential is still being wasted here too, as the zero-point clamping system is often only placed in the centre of the machine table for simple single clamping. The remaining space often remains unused. As safe as zero-point clamping systems are, efficiency can certainly diminish at this point.

The Quick•Point® Rail clamping system puts an end to this and can be used more efficiently than many zero-point systems. It can be installed in any CNC machining centre and does not require a base plate.

Expanding the range of tasks

Quite simply by moving the clamping device variably using the Quick•Point® Rail clamping bars. The length will depend on the component length as anything is possible with combinations – especially when two clamping devices are in use. The distances between the two clamping devices can be flexibly adjusted using the Quick•Point® Rail clamping system. This is made possible by a 4mm grid that can be moved back and forth as required.

Risers are also frequently used in the zero-point clamping system to increase the distance between the machine table and the workpiece. Once inserted in the zero-point clamping system, these are firmly locked in place on the automation pallet or machine table. With the Quick•Point® Rail quick clamping system, a zero-point riser can now be moved for the first time and still leave the desired space. The Quick•Point® Rail takes just a few minutes to install and turns a reliable zero-point clamping system into a movable zero-point system with a wide range of options.

The quick-clamping system makes use of the existing conditions in the machine tool. Quick•Point® Rail can be fastened in the grooves of the machine table. This is done with the aid of sliding blocks. The clamping bars are fixed above this using cylinder head screws. If you are working with automation pallets, simply screw the clamping bar of the Quick•Point® Rail clamping system directly onto the automation pallet using the existing threaded holes. The clamping rails are available in different versions so that it can always be guaranteed that the available width of the base is ideally utilised. The Quick•Point® Rail starts with performance improvements where every machining task begins – increasing the clamping efficiency.

Innovative tools for creative metal-cutting

Innovative tools for creative metal-cutting

Companies that manufacture one-off parts and small batches primarily for the mechanical engineering industry require tools that are versatile all-rounders. Just as important is a tool partner who understands what metalcutting is all about and can ‘read’ the production process. If the partner just happens to be located in the region, then they are just the right partner. Otto Beckert Feinmechanik GmbH & Co. KG discovered this when it turned to ARNO Werkzeuge not only to supply turning, milling and drilling tools but also advice and assistance.

“We think European and that’s how we buy. Even if our work is focused on products and applications for the world market, we aim to keep the added value here in the region. After all, most of our customers are also from this region,” stresses Ralf Beckert, Managing Director of Otto Beckert GmbH & Co. KG in Kirchentellinsfurt. The medium-sized manufacturer is an innovative solution finder and most of its customers are located within a 50km radius.

Customers include well-known machine manufacturers as well as suppliers to the semiconductor industry, powertrain specialists and other global market leaders, of which there are many in the Stuttgart region. The company’s management attaches great importance to regional responsibility and a stable supply chain with rapid response and personal dialogue. This is why ARNO Werkzeuge GmbH with its universal cutting tools has been a dependable partner.

With 40 employees and 19 CNC machines that produce high-quality components from all conceivable materials, batch sizes range mostly between one and 100 or small runs up to 2,000 parts. Customers come from the motorsport, medical, drilling platform and chip production industries. “Frequent tool changes foul up any calculation,” says Kevin Göhner, Industrial Mechanic and CNC operator at Otto Beckert.

The aim is not to squeeze the last hours, minutes or metres of tool life out of a tool. The essential thing, he finds, is universal tools that can be used for as many processes as possible and a wide range of materials. Here is where Tobias Breitling from ARNO Werkzeuge has arrived with the right products.

The technical consultant also comes with a wealth of application knowledge and universal products for efficient machining. One highlight is the patented DuoMill FD milling system. With only one basic body, the tools can be used for corner and high-feed milling operations on steel, stainless and aluminium. “And you can even do this from a corner radius of just 0.2mm, which is virtually unrivalled,” assures Breitling. The fact that corner and high feed inserts are mounted in one insert seat is unique and patented. To machine non-ferrous metals, the indexable inserts are precision-ground and polished around their entire circumference. In addition, the nickel-plated long-life basic holders with four cutting edges per insert allow a high feed rate.

Efficient milling with unique patented tools

Universal tools with these features not only have a positive effect on tool change times but also the cost of the tool holders. They simplify handling, storage and stocking. “The fact that two different types of indexable inserts can be mounted on the same tool holder provides our customers with enormous flexibility,” says Breitling. “And flexibility is our top priority,” adds Beckert. The product range includes screw-in end milling cutters from 25 to 42mm diameter, as well as shell-type cutters with diameters of 40 to 160mm.

The differential pitch of the tool holders significantly reduces vibrations during milling. Four efficient cutting edges at 90° angles ensure high efficiency in corner and high feed milling operations. “This is the real strength of the DuoMill and produces very smooth surfaces as a result,” says Göhner. Breitling explains that in some cases, it can even eliminate downstream work steps. “If you want to work both rapidly and at high precision, you should opt for our FD milling system.”

Showing the workpiece more teeth

Milling, roughing and finishing at 90° requires a lot of material removal, so Otto Beckert switches to the all-around BLN corner milling system. When a solid tool holder, large and stable indexable inserts and an infeed of up to 12mm come into play, there is no stopping them. “The machine is more likely to fail than the tool,” surmises Breitling.

Göhner also enjoys using the FT face milling systems 09 and 12 with the same enthusiasm. They consist of stable tool holders with more teeth and smaller indexable inserts to match. Here too, the tool holders have a differential pitch that also ensures a smooth milling process with less vibration. “We can run at significantly higher feed rates and achieve a higher metal removal rate, especially with small allowances,” says Göhner, adding that time and flexibility are crucial factors.

“Despite the small diameter, we can place more teeth in the tool,” explains Breitling. Whereas previously there was only room to fit six indexable inserts, now up to nine can be installed. This reduces throughput times and costs. The indexable inserts also cut very softly and this reduces wear on the spindle and machine. So, when the FT face milling system is tooled with cutting edges and matching smaller indexable inserts, it covers a diameter range of 20 to 125mm.

Parting off and grooving

In process optimiser, Tobias Nagel’s opinion, the SA parting-off tools with flange-mounted holders that Breitling has in his bag are indispensable for lathes. He likes to use the two-edged SA parting and grooving system with grooving widths of 1.5 to 10mm for grooving and parting off at large grooving depths of up to 140mm in diameter. “That’s important for us, so we don’t have to change so often,” explains Nagel. The parting-off tool, together with its many modules, holders and blades, is ideal for many applications at Otto Beckert. Nagel also appreciates the wide variety of matching flange-mounted holders for various machines.

The patented ACS (ARNO Cooling System), which the manufacturer developed specifically for parting off, is an extremely important factor. In the ACS 2 variant, the coolant channel at the insert seat is coupled with a second jet that sprays coolant from the bottom onto the tool flank. The coolant channel is a 3D-printed variant and has a triangular optimised-flow shape which supplies coolant across the full width of the insert right through to the edge of the cutting edge. Nagel is therefore delighted with the tool life that is three times longer.

Icing on the cake for drilling

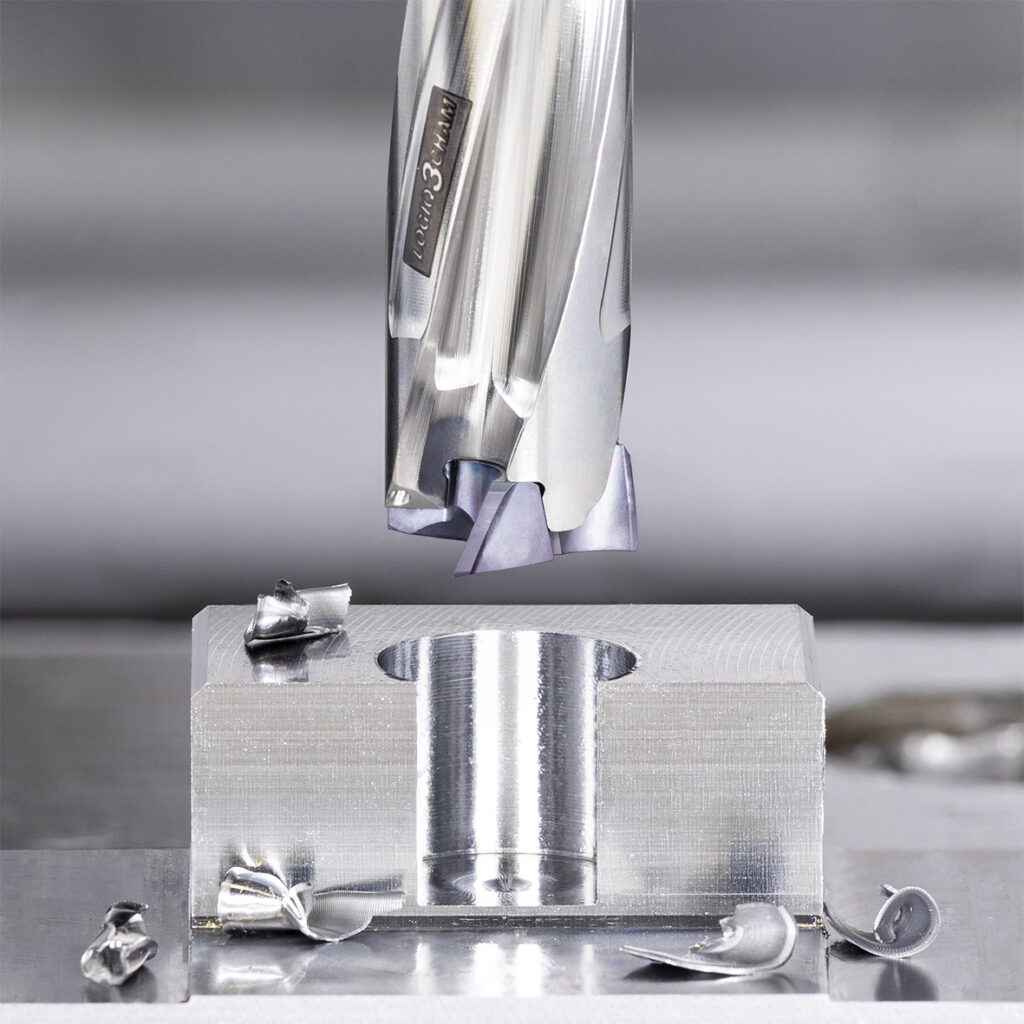

The machining specialists are also thrilled about significant savings when it comes to drilling. That’s because Breitling introduced the insert drilling system. The core drills are designed for stationary or rotary operations. Depending on the application, ten types of coated and uncoated inserts in four geometries can be attached to a range of twelve spiral or straight-fluted tool holders.

They do not need the full diameter range from 14 to 32mm by any means. “But they replace our solid tungsten carbide tools for diameters from 14 to 20mm. That cuts our costs by a huge amount,” says Beckert happily.

A SMART, new machine tool for the UK & Ireland

SMARTEK CNC LTD has recently been appointed as the UK and Ireland agents for the Korean-manufactured SMART MACHINE TOOL (SMT) range of machine tools. As the UK & Ireland technical partner for the high-quality range of SMART MACHINE TOOL turning and machining centres, SMARTEK CNC LTD is already reaping the rewards of introducing this new brand of machines to UK manufacturers.

As a company, SMARTEK CNC was incorporated following a collaboration between two highly experienced CNC service engineers, Kevin Wright and Bobby Graham. Kevin and Bobby often had conversations regarding starting a machine tool business that could offer high-quality machine tools with an aftersales service and support package to match – a combination often lacking with many machine tool vendors.

The highly skilled engineers met when employed by another machine tool agency that also worked with a South Korean manufacturer. On achieving access to the SMART MACHINE TOOL range Kevin commented: “Even as an established agency, being selected to represent a machine tool builder is extremely rare, but to be presented with this opportunity as a new entity is unheard of. We are fully committed to ensuring that we do justice to these quality-built machine tools.”

SMART MACHINE TOOL has manufactured CNC machine tools in the Republic of Korea since 2018 and its brand and product portfolio continually expands. The shareholders of SMT have a combined experience within the machine tool industry of over 100 years, having worked previously for various prestigious South Korean machine tool manufacturers.

The Chairman and majority shareholder of SMART MACHINE TOOL is Mr Richard Layo, who is also the owner of Dynamic International, a Wisconsin-based dealership, that has been importing high-end CNC machine tools into North America since 1986.

Regarding the SMART products Richard states: “Since introducing the SMART NL series of CNC Lathes and NV Vertical Milling Machines, we have sold more than 2,000 machine tools to North America, Canada and Europe. Our NL range incorporates a boxway slide design that delivers a rigid and robust machine with genuine power and accuracy. This provides a highly productive platform that also has a reliable and aesthetically pleasing overall build.”

When questioned as to why SMT has chosen SMARTEK CNC to join the SMART family, Richard proudly responds: “We’ve had great success in recruiting machine tool service engineers to represent us in the form of agents, as we believe they have a unique relationship with prospective customers. These engineers have been trusted to repair existing machinery and have been relied upon to maintain expensive equipment. Who is better positioned than Bobby and Kevin to present our range of machine tools in the UK & Ireland, to their existing customers and enhance our growing reputation”

Discussing how SMARTEK CNC expects to sell an unknown product into a marketplace that already has a substantial amount of well-known machine tool suppliers, Bobby comments: “We have already been fortunate enough to have had an existing customer of Kevin’s, who respects Kevin’s opinion well enough to place his faith in us and they have already placed an order! As experienced engineers, we are extremely confident in these machines. We have visited various users in the USA and seen how well the machines perform – when you combine this with an unbelievable and completely open pricing strategy, we know more orders will follow. We are extremely grateful to Richard for giving us this opportunity and we are beyond determined to make our ‘SMART’ partnership, extremely fruitful and fulfilling for both parties”.

Aerospace subcontractor improves efficiency with Citizen

Aerospace subcontractor improves efficiency with Citizen

Specialising in the manufacture of precision components for the aerospace industry, subcontract machining firm Apel began investing in Citizen CNC turning centres in the 1980s to help raise efficiency. Founded in 1965, the company has over time continued to re-invest in modern, highly productive lathes purchased exclusively from Citizen Machinery UK.

Nowadays, Apel operates nine Cincom sliding-head lathes and one Miyano fixed-head model at its Wilmslow facility. Together they produce around 50,000 components per month across more than 3,000 part numbers. Utilisation of these Citizen CNC lathes and related technologies has led to significantly increased levels of productivity and profitability.

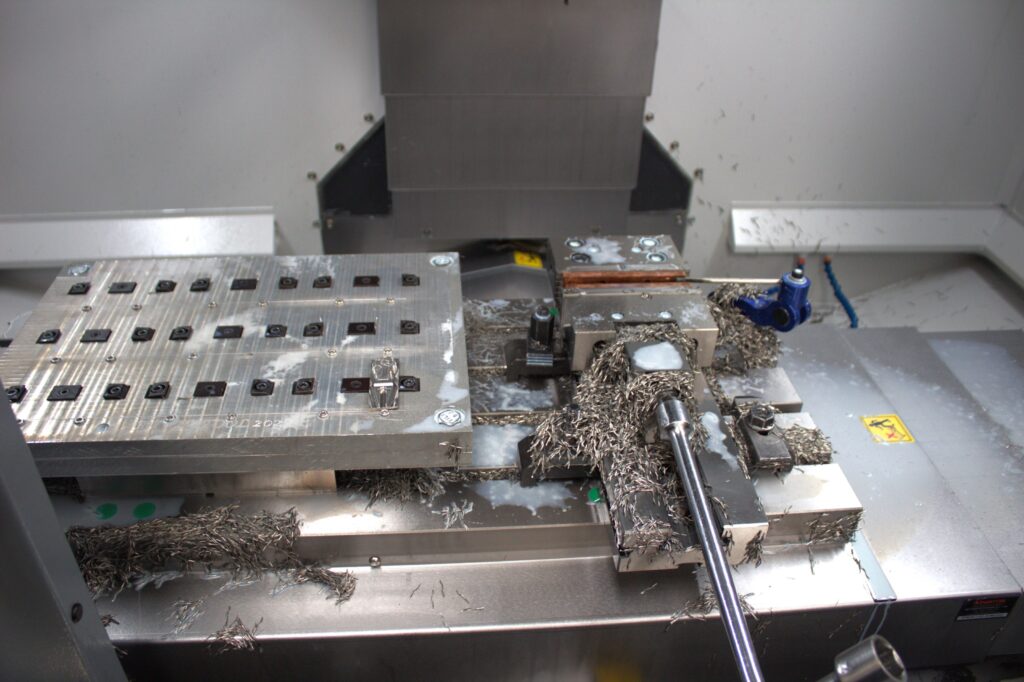

The technology that has contributed most to raising the efficiency of production at Apel is Citizen’s proprietary LFV (low-frequency vibration) chip-breaking software, which is part of the operating system in the control of three of the six 20mm capacity Cincom L20s on site. When activated, the function breaks what would otherwise be long, stringy swarf into short, manageable chips. Around 50% of the material processed by Apel is aerospace-grade stainless steel bar. LFV is especially effective when processing this alloy.

Paul Bowker, Apel’s Quality Director said: “We were an early adopter of LFV in 2018 following a visit to Citizen Machinery’s technical centre in Bushey to witness demonstrations. The function reduces the metal removal rate slightly, so we don’t use it all the time, but it’s really useful to be able to pick and choose when to program the function to start and stop. We switch it on mainly when turning stainless steel components on the LFV-equipped machines, especially when processing parts shorter than 25mm. It is normally chip breaking the metal for up to half of a typical cutting cycle.”

He further explained that the decision to use LFV is also based on the surface finish required on components. Some customers’ drawings stipulate a very high surface tolerance and machining with the LFV function switched on allows this to be achieved by turning alone. It avoids the need to centreless grind parts afterwards, thereby reducing unit manufacturing costs and raising profitability. Dimensional and surface finish tolerances on many component drawings can be met and maintained when using this facility.

Apel also uses Citizen’s adaptive guide bush (AGB) system. This automatically compensates for variation in bar diameter, preventing the stock from seizing in the bush. It also constantly maintains concentricity to prevent run-out issues. Downtime is avoided and tight machining tolerances are maintained. The system is used not only on the 20mm capacity sliding-head lathes but also on three 32mm capacity Cincom models on the shop floor.

The aerospace sector is very busy presently and Apel is well placed to win work due to the quality management system it operates, competitive pricing and the many industry and customer approvals it holds. Exports account for 20% of turnover with India and Saudi Arabia being major overseas markets.

The AGB systems ensure reliability during unattended operation by compensating for bar diameter inconsistency and preventing stoppages. Additionally, the LFV machines do not have swarf clogging the working area when processing stainless steel. It contributes further to reliability and eliminates the need for an operator to be in attendance to untangle ribbons from the components and tooling.

Mr Bowker concluded: “Our nine Cincoms, as well as the Miyano for turn-milling larger components up to 50mm diameter, support all of our production and will continue to do so as we increase our volume of work in the expanding global aerospace industry.”

Selecting Toolholders

Tool holders play a critical role in connecting elements and maximising performance. With several types available, the most suitable one for your application will depend on the operation. Consider key characteristics as they will differentiate a standard tool holder from one that’s the right choice for precise machining.

Selecting a high-speed tool holder that will consistently produce high-quality, machine shops need to focus on balance, taper contact and accuracy. Alan Miller, Senior Engineering Manager at BIG DAISHOWA, the brand available from Industrial Tooling Corporation (ITC) discusses why these aspects are top priorities for manufacturers and reveals the attainable outcomes of each.

Taper considerations

For precision machining, the taper must be manufactured to extremely tight tolerances for the tool holder to provide a rigid connection for the axial and radial loads. Good repeatability in and out of the machine must be consistent. The requirements will depend on the tool holder used, such as the HSK, CAT/BT, and polygon styles. HSK are hollow shank tapers and available types include the A, E, and F. These offer radial stiffness and high-speed precision. This taper is much shorter (25 to 125mm) and has a mechanism for radial and axial connection.

“Since this is a small hollow taper, material selection is extremely important,” Miller says. “HSK is clamped by fingers reaching inside the hollow core and stretching the taper back into the spindle. The wall thickness is very thin and it’s critical to have a high-quality grade of steel.”

Another consideration for HSK is the finishing of clamping features after heat treatment because the fingers reach inside and grab on a feature inside the hollow taper. So, making sure it’s finished after heat treatment assures it’s in the correct location.

CAT and BT style are steep taper holders with a traditional style cone. Both have a 7:24 taper ratio and require a pull stud to secure the holder. As the machine grabs and pulls, the spindle expands to secure taper contact. With the larger size and the cone shape spindle, the taper will open as speeds increase. As the spindle opens, the force of the clamping unit draws the holder deeper into the spindle, causing the loss of accuracy.

To address this issue, BIG KAISER’s BIG-PLUS spindle system (BBT) available from ITC allows the shank to contact the spindle taper and the spindle face simultaneously, allowing increased tool rigidity due to the larger contact diameter of the tool holder flange face. This works together to resist deflection.

The polygon tapers put the face and taper of a machine spindle and tool holder in contact, ensuring high repeatability. The polygon design also allows for self-centering to improve accuracy. However, these types are more difficult to grind because of the slope, so it takes a high-end machine to achieve the desired accuracy.

As spindle speeds increase, it becomes more important to obtain tool holder balance. Balanced tool holders allow users to run at high speeds and feeds while maximising tool life, surface finish and spindle life. Balancing ensures the tool consistently engages with the material to prevent chatter and poor surface finish.

“For balance, we’re talking about side loads generated by that unbalanced mass running at high speeds,” Miller explains. “So, that can influence the bearings of the machine spindle to the actual cutting performance at the business end of the tool. It’s very important to consider, and there’s a new ISO toolholder balance standard that was released in 2017 to help users.”

The updated ISO:16084 standard accounts for all variables for safe machining. It also considers factors that can lead to imbalance, like the interaction between the spindle and tool, factoring in allowable loads on spindle bearings generated by tool imbalance.

The best way to ensure balance is to measure the tool holder as a full assembly. Ultimately, this results in a better-performing tool. Although each part can be balanced individually, this will not guarantee the highest level of overall balance. The benefits include optimal surface finish, machine sustainability, better part geometry and extended spindle life.

Miller also cautions: “When dealing with balance, there’s also a plateau point, where additional balancing won’t help anymore. The goal could be exact balancing, but we’re going to spend a lot of time on every tools, trying to achieve that same amount of balance. No matter how much more balancing you do, it won’t change the way the tool performs.”

Accuracy

Improved quality will depend on the accuracy of the tool, which is largely affected by tool runout. Very low runout of the holder will give better quality and improved cutting for more consistency and lower costs.

“Runout accuracy is a very important consideration. Low runout will give better part quality and it will improve tool life and allow you to get more consistency, longer run times, and fewer tool breakages,” Miller adds.

BIG DAISHOWA designs and manufactures tool holders to reduce runout, by using precision materials, production processes and heat treatment selected for precision. This includes pull studs built with through-hardened H13 tool steel where all features are precision ground. Each collet is inspected for 100% concentricity, guaranteeing runout within 0.001mm at the nose. Most of the customer base follows guidelines of 0.007mm to 0.0013mm to be a good runout. This may only give 50% to 60% of the potential cutting tool lifespan.

“Our programs are down to 0.0002mm and 4XD to make sure you have accurate tool assemblies,” Miller says. “All of our collet chucks and finishing tool holders guarantee that runout accuracy is about 3 to 5 times better than what is considered good.” Runout can also impact cutting force, which can cause vibration and ultimately inhibit machining accuracy. “Vibration is challenging the function of the cutting parameters, mostly back to the cutting speed and rotational speed,” Miller explains. “The best tip that we have for anyone experiencing vibration is to adjust the speed in one direction or the other, change lanes and get into a harmonic situation.”

Getting in gear with Vargus

Taking the opportunity to see new technology in the flesh can very often be the light bulb of innovation for manufacturers – the recent MACH exhibition was a casing point. At this year’s MACH exhibition, cutting tool specialists Vargus UK presented their latest range of gear milling tools, the Vardex. This system brought the realisation to many manufacturers attending the show that they don’t need specialist gear-cutting machinery to generate gears.

For years, this niche area was the reserve of specialist manufacturers with gear-cutting machine tools. However, the onset of more advanced multi-function turn/mill centres and multi-axis machining centres means that activities like spline milling no longer have to be subcontracted out as a specialist service. As Vargus UK Managing Director Graeme Troughton says: “We had a live gear machining process running at MACH 2024 and this was a revelation to so many engineers. After the MACH show, we had a customer who had seen our gear machining process running live at the exhibition. Following this, we were invited to trial at this Midlands-based company. Compared to their existing conventional hobbing process, we reduced the cycle times by more than 65%.”

“However, this is not the full story as previously, this customer was also subcontracting additional work out. Not only was the customer losing control of their processes, but they had to endure a 6-week lead time for parts and this all came at a cost that was double the price of the tooling from Vargus which will last for years to come. By switching to our system, the customer can now quote shorter lead times, offer more competitive pricing and control the full process themselves, factors that will undoubtedly lead to this company winning more of this type of work,” adds Graeme.

This is just one example of what can be achieved with the Vargus Vardex gear machine technology. Hobbing has always traditionally been the common process for gear, spline and rack machining, but now Vargus offers a solution with its Vardex gear milling tools that are a competitive alternative to traditional hobbing. To meet the wide demands of industry, Vargus offers four types of tooling solution – indexable end mills, shell mills, disc mills and solid carbide tools. For gear milling, the Vardex gear milling tools are suitable for machining straight gears covering modules from 0.5 to 6.0mm or DP 52-4, these identical parameters are also covered by the Vardex rack milling tools. Concerning spline milling tools, the Vardex system is suitable for machining both involute or straight-sided profiles covering modules from 0.5 to 0.8mm or DP 48/96-4/8. Complementing these solutions, the TM solid carbide series provides an excellent alternative for applications that require cutting close to the shoulder. Suitable for both gear and rack modules, the solid carbide series can work in parameters from 0.5 to 2.0mm with DP52 to DP13 whilst the spline module range applies to 0.8 to 3.0mm with a Dp40/80 to DP8/16.

The advantages of the Vardex gear milling concept is multi-fluted indexable carbide grade inserts for superfast machining that offer a competitive alternative to traditional hobbing systems. Furthermore, this innovation provides exceptional tool life, high accuracy and impeccable surface finishes that yield an economical option with simplified machining.

What comes next?

What comes next?

In the May issue, we featured our European trip with Ceratizit that took in the fantastic sights of Ruette, Kreckelmoos and Kempten in Austria and Germany to see the investment in new production sites, a new logistics facility and the brand new tech centre. In the run-up to the Autumn exhibition season with AMB and IMTS on the horizon, we take a closer look at some of the innovations shown during the tour that will be making an appearance at these September events. By Rhys Williams

The May issue of MTD magazine covered Ceratizit’s major investments, the sustainability targets and how they are being achieved. We also captured some of the new technology in the pipeline. This month, we take a closer look at the innovations that were put through their paces during the event – this is particularly pertinent as some will have been seen at MACH whereas others will be uncovered for the first time during the Autumn exhibition season.

Following an initial presentation, a tour of the Reutte manufacturing facility in Austria and a spot of lunch, our touring press party was invited to participate in technical demonstrations. These presentations covered everything from the sustainability journey and the roadmap for the future, additive manufacturing and of course the live machining demonstrations. The first demonstration conducted on a DMG MORI CTX1250 involved the turning of a steel billet with the use of the EcoCut multi-functional tool for face and profile turning.

Considered the ‘Swiss Army Knife’ in Ceratizit’s toolbox, Ceratizit customers will know that this range has been around for some time. However, the demonstration was of the new Dragonskin ISO-P steel grade launched in February. This new grade has proven to extend tool life by 15% under trials. Alternatively, users can increase their cutting data and retain the same longevity as their existing Ceratizit grades. An impressive start, but what came next was somewhat different…

Following the profiling of a billet with EcoCut was FreeTurn. Initially launched in 2019, this gem was a lightning rod innovation that won awards when it landed. However, machine tool manufacturers, CNC control manufacturers and CAM developers were somewhat caught napping with only OPEN MIND’s hyperMILL and a few machine tool brands having the capability to work with FreeTurn. Capable of making huge productivity gains and equally impressive tool life savings, this groundbreaker was waiting for the industry to catch up. While the industry has been catching up with High Dynamic Turning (HDT), Ceratizit went ahead and developed and evolved CERASmart – but we’ll circle back to that.

High Dynamic Turning (HDT) is now available with most CAM developers with CNC control manufacturers having some functionality, but still playing catch-up. Why is everyone starting to sit up and pay attention? Well, FreeTurn can increase feed rates by 40%, reduce ‘air-cutting’ toolpaths by 90% and reduce machining times by at least 25%. However, to take advantage of this, manufacturers need a turning centre with a Y-axis milling spindle and an HSK-T or PSC interface.

Running Free With Innovation

Ceratizit ran FreeTurn on the DMG MORI CTX1250 TC as it fulfils all the requirements of HDT. It is both HDT-ready and counts among the most commonly used turn/mill centres on the market. “This means we can confirm that it’s already possible for many manufacturing companies to use HDT and FreeTurn,” explains Product Manager Paul Höckberg.

The component, the base body of an indexable insert drill was optimised and entered using the Siemens Sinumerik 840D control system and a 5-axis simultaneous cycle from OPEN MIND, resulting in astounding cutting speeds. Just to highlight the benefits of this demo – It ran at a cutting speed of 220m/min, a feed of f0.48mm/rev and a depth of cut ap 4mm. During finishing, a cutting speed of 400m/min was applied. “We knew our FreeTurn was good, but we never thought it was possible to machine structural steel (X40CrMoV51) at such high cutting speeds,” marvels Höckberg.

Instead of using three different tools that would usually have been required, the component is now produced with only one FreeTurn tool, saving the use of two tools and reducing the production time from 5:10 to 2:45 minutes.

For manufacturers that can see the merits of this technology, Ceratizit has developed CERASmart – a system that enables manufacturers to quickly and easily generate NC code to create tool paths for HDT with FreeTurn tools….and much more! This ‘plug and play’ system can be installed on a PC or directly to a machine tool CNC and customers can then import DXF files to the software. CERASmart permits dialog-based programming and generation of standard NC code for machines regardless of component complexity and it also allows the dynamic cutting angle adjustment for tool paths along the component contour. With Ceratizit tool data pre-defined in the software, optical simulation and optimisation of tool paths and movements are available in the software without requiring a 5-axis ‘option’ that is normally needed for simultaneous turning.

The CERASmart software for HDT FreeTurn programming is not available to download yet, but Ceratizit expects this to be available for the autumn exhibition season. Why should you be looking at it? If you are heavily involved in turning, the benefits of HDT and FreeTurn have already been emphasised, but concerning CERASmart, it now incorporates HDT with FreeTurn tools specifically for customers to take full advantage of. It allows shop floor programming without CAM and integrates smoothly without interrupting existing programming processes. Furthermore, it incorporates collision avoidance via its simulation and optimisation capabilities and this is all available at a minimal investment when compared to a full CAM solution. The demonstration on the DMG MORI machine was concluded with the FreeTurn tool being replaced by the MaxiMill Slot-SX grooving, parting and slotting system.

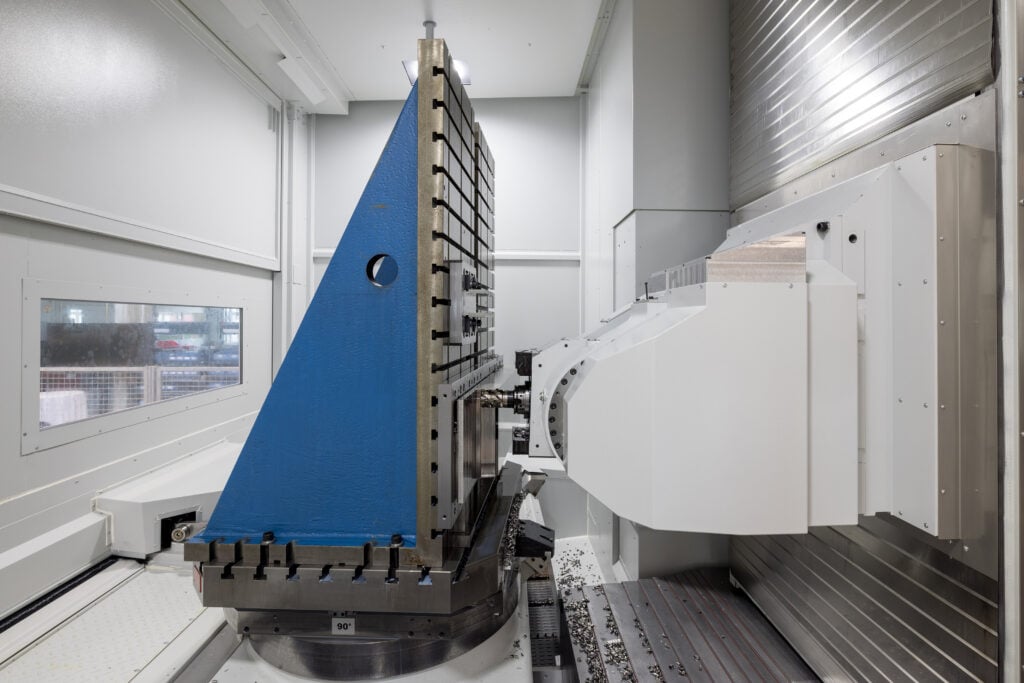

Moving to a Mazak MTV815/15 machining centre, the Ceratizit team presented the MaxiMill extended flute porcupine cutter that ran at a cutting speed of 160m/min at a feed rate of 50mm/rev. Utilised by Airbus in France for titanium structural parts, both the Ceratizit engineers and the MaxiMill tool were not shirking away from the challenge of cutting P35 steel in anger. The demo part then underwent slotting and shoulder milling with the MaxiMill 211-15 Shell Mill at a cutting speed of 180m/min before the MaxiMill Shell End Mill was applied to complete the part with helical milling and contouring.

Heading off the shop floor to the solace of a quiet meeting room, Ceratizit then presented more of its latest cutting tool innovations. This included the new MaxiLock N-DC introduced to the industry in February. The (DC) DirectCooling product range has now been added to the MaxiLock-N turning tool holders and this provides two coolant holes that aim coolant directly at the cutting edge, preventing wear and ensuring stable processes.

With three nozzles aimed at the clamping flat of the turning tool from above, another is directed at the flank from below – specifically at the cutting edges. This targeted cooling system is suitable for all materials, although it delivers advantages with ISO-P, M and S in particular due to the rapid heat development in the cutting process. “It is precisely this flank cooling that makes the difference. It extends tool life by 60% compared to cooling that is exclusively aimed at the clamping flat,” explained Stefan Karl, Product Manager of Cutting Tools.

This (DC) DirectCooling has also been added to the Ceratizit range of tried-and-tested MaxiLock-S turning tools. Similar to the MaxiLock-N, the MaxiLock-S holders feature two internal holes ensuring that the coolant is applied precisely to the cutting edge. One hole targets the rake face from above and the other hits the flank from below. Again, this flank cooling system is said to boost service life by 60% compared with cooling exclusively on the rake face.

The final tooling innovation for the day was the Multilock exchangeable head system. Ceratizit customers will know the name has been around for several years, however, the company now offers both steel and carbide tool bodies with exchangeable heads, now offered as precision sintered cutting heads that are not ground. The benefit is a reduced manufacturing cost that is passed to customers who can now acquire reduced-cost sintered cutting heads whilst retaining performance characteristics. The application of carbide and sintering processes was particularly pertinent considering our next presentation.

Turning the impossible to…

….making the additive printing of cemented carbide products possible. Demonstrating its position as a pioneer in carbide research and production, Ceratizit analyses trends to offer optimal solutions. It has now developed additive manufacturing technologies for its cemented carbide grades that enable it to offer carbide-manufactured parts with unlimited design possibilities. The 3D printing of carbide products delivers technological possibilities to overcome design limitations and create designs with minimal batches. Offering simulation and modelling, design adaptation and material selection support, Ceratizit can take manufacturers from the ore to the ready-to-use tool.

With the facility to print every cemented carbide grade from coarse to ultrafine and offering a complete variety of binding agents and levels of binder content, Ceratizit can manufacture everything from wear-grade carbides to grades for cutting tools. Utilising a complete range of printing technologies to provide maximum flexibility with both the powder and binder composition, the design freedom, turnaround times and scalability of production volumes are making this technology a genuine opportunity area.

And of course, there are the environmental benefits. During a presentation, Dr Manuel Walch discussed a formed tool from a sintered block that required EDM processing to attain the final net shape. This example highlighted how eroding a form tool from a carbide block with a weight of 574g required erosion of starter holes, cavity cutting, the removal of scrap and re-wiring the wire EDM machine. With all this effort, the process left 341g of scrap whereas a 3D printed carbide form tool could be printed near net shape with a weight of 260g requiring a finishing cut that resulted in just 28g of scrap. With a material saving of more than 60% over conventional methods, it is evident why Ceratizit is pursuing this route.

Building for the Future

On the final day of the tour, the press delegation crossed the border to Kempten in Germany where we visited the brand new sales and technical centre. When I say ‘brand new’, this site opened on a Monday and we toured it on Wednesday. Some of the staff in this facility with 5,000m2 of meeting rooms and 725m2 of tech centre hadn’t yet learnt where the bathrooms were.

The second tech centre of the tour was of course filled with brand new machines and the first set of demos was conducted on a DMG MORI DMC90 U. This provided an opportunity to showcase the WTX-TB UNI 50XD deep hole drills. Available in diameters from 0.8 to 2.9mm, the WTX micro-drills may be a name familiar to customers who have previously purchased 5XD to 20XD variants and the more recently introduced 25XD and 30XD drills. However, pushing the envelope even further, Ceratizit showcased the new 50XD drill. Anybody applying 50XD micro drills can appreciate the potential for drill breakage, so this was an opportune moment to give the audience a demo of its ToolScope suite that sits within CERASmart to measure everything from the tool load and cutting parameters to machine usage, hours, number of stops, the programmes running, alarms and usage by specific tool – and much more.

Trochoidal milling followed with the CCR-UNI 5XD tool and then came the revelation that the next tool was manufactured from 99% recycled carbide substrate. The ProACT-Mill UNI solid carbide milling cutters are a new independent upGRADE product line of universal milling cutters that combine performance with sustainability. The ProACT-Mill features the same performance as all-around high-performance milling cutters with the most sustainable carbide substrate, providing an economic and ecological advantage. You’ll be able to discover more during the autumn exhibition season on these tools.

Circular Economy

The new recycled ProACT milling line is supplied with data matrix codes on the tools and this connects to the ToolCycle module that feeds back to the previously mentioned CERASmart suite that has the facility to provide the entire life-cycle of the tool via its ‘digital twin’. Within the CERASmart suite sits ToolScope which has been available for several years. Like any software platform, if it receives the right level of investment and innovation the growth can be exponential. Now, the system offers complete process monitoring of tools and with fast-acting mechanisms, tool defects can be detected and machining stopped before any tool is damaged.

ToolScope collects, displays and evaluates data and detects deviations in real-time, allowing customers to intervene in production processes. The machine condition is also monitored for maintenance purposes, making ToolScope act like an airbag inside the machine. It also prevents overloading of the tool and the machine with data recorded for full tool service life analysis. ToolScope incorporates process monitoring, wear detection, adaptive feed control and collision detection, and with functions individually tailored to the customer, tool life improvements and cycle time reductions are easily achievable. Ceratizit is continually evolving the system and it has now introduced a series of iTENDO hydraulic toolholders with sensors that can communicate directly with ToolScope to enhance the feedback loop and machining performance further.

As a critical element in the overall CERASmart suite, ToolScope is an impressive data collection tool that feeds back to CERASmart which itself has been expanded to incorporate data from ERP systems, tool and quality management systems and also ToolCycle. This central portal of information is an Industry 4.0 solution that enables customers to collate data to make better-informed decisions, automate and streamline processes and also create a feedback loop with experts from Ceratizit. A fascinating system, Ceratizit is continually evolving this portal and the HDT FreeTurn programming suite is just one in a long pipeline of innovations to come.

Aerospace delivers decade of ‘staggering’ growth

Aerospace delivers decade of ‘staggering’ growth

ADS Group’s latest annual report shows bullish growth across the aerospace, defence, security and space sectors, with aerospace, in particular, continuing to rebound strongly from the pandemic. These industries contributed £38.2bn in gross value add (GVA) to the UK economy, a sizeable increase from £37bn the previous year and almost 20% of total manufacturing GVA. Turnover rose to £88.4bn, up from £82bn, and exports to £38.7bn, compared to £36bn. Direct employment also experienced a sizeable uptick, reaching 427,500 jobs, up from 417,000.

As uplifting as these year-on-year increases are, the true scale of expansion becomes more apparent when viewed over a somewhat longer period. For the first time, the 2024 report includes ADS’ analysis of how the UK aerospace, defence, security and space sectors have performed over the past decade.

Between 2013 and 2023, these industries delivered ‘truly staggering’ growth, as described by one spokesperson: GVA increased by 50%, turnover by 40%, exports by 32% and employment by 29%. That the past decade has been marked by frequent disruption, downturns and delays makes this more remarkable.

Aimie Stone, Chief Economist at ADS, says this success is due to aerospace, defence, security and space is reliant on a highly skilled workforce, a strong culture of innovation and the rapid development and adoption of new technologies and techniques.

WORLD-LEADING R&D

The Aerospace Technology Institute (ATI), for example, plays a pivotal role in advancing the UK’s global reputation for innovation. Celebrating its 10th anniversary in 2024, the strategic partnership between industry and government has a particular focus on cleaner and greener air travel.

Since its creation, the ATI programme has allocated £3.6bn of joint government-industry funding to more than 400 aerospace R&D projects across the UK. Notable successes include the Rolls-Royce UltraFan demonstrator engine, which reportedly boasts a 10% efficiency improvement over the Trent XWB, the world’s most efficient engine in service today.

Another key initiative is the Airbus-led Wing of Tomorrow programme, which is developing the next generation of carbon composite aircraft wings. A new Wing Technology Development Centre (WTDC) recently opened in Bristol and is now working in parallel with Filton’s existing Aerospace Integrated Research and Technology Centre (AIRTeC), which opened in 2021.

Other research facilities that have benefited from substantial ATI investment include the Osney lab in Oxford, the new Whittle Lab in Cambridge and the National Centre for Combustion and Aerothermal Technology in Loughborough.

Alongside supporting global OEMs, the ATI is also helping nurture the UK’s thriving ecosystem of SMEs, such as ZeroAvia, developing hydrogen-electric engines for zero-emission flight. Reflecting on the 10-year milestone, Val Miftakhov, Founder and CEO of ZeroAvia, says the ATI’s impact on advancing zero-emission hydrogen engines within the industry is of ‘huge importance.’

He says this will not only help deliver “a clean future for flight” but predicts it will bolster the UK’s ability to “capture more exports as the world becomes reliant on cleaner propulsion technologies.”

SOARING EXPORT GROWTH

Strong export performances underpin growth, generating nearly half of the combined turnover. The security sector has seen tremendous export growth of 228% since 2013, demonstrating the growing global demand for the UK’s cutting-edge security technologies and solutions.

Geopolitical tensions and proliferating international security challenges have also heightened demand for advanced military equipment and cybersecurity measures. The UK has established itself as a leading developer of high-tech defence systems, whether on land, sea, beneath the waves or in the air – manned, partially unmanned or fully autonomous. This strategic positioning has led to a substantial 28% year-on-year increase in defence exports.

ADS’ Aimie Stone expects defence exports to continue to grow, driven by the UK’s continued strengthening relations with the EU, collaborative efforts with NATO allies and participation in major international programmes such as AUKUS and the Global Combat Air Programme (GCAP).

Rising passenger demand for long-haul travel and renewed interest from airlines in updating their fleets with more fuel-efficient and technologically advanced aircraft have seen record-breaking global orders for widebody aircraft – up 169% in 2023 compared to 2022. This trend will bring significant benefits to the UK, says Stone, as almost 20% of the value content of widebody aircraft comes from the UK, with engines and wings representing the largest share.

One company reaping the benefit is Arrowsmith Engineering, whose overseas sales have rocketed by nearly 400% following the pandemic and now account for a third of its £8.3m turnover. Precision components manufactured at its Coventry factory are shipped to customers in Brazil, China, France, Germany, Singapore and Spain for use in aerospace engines, landing gears and airframes.

Shortly after receiving its second King’s Award for International Trade earlier this year, Arrowsmith Engineering announced a string of new contract wins, resulting in the largest order book in its 57-year history. According to Jason Aldridge, Managing Director, investments in new technology and robotics, along with the creation of 10 new jobs, have provided the capacity and capability to win work against much larger rivals.

The company recently expanded its capacity further with the delivery of two additional dual spindle Lynx 21000ISLYA/B CNC machines from Mills. This follows the success of its installed 5-axis DVF5000 and 4-axis DNM4500 cobot systems.

A LONG-TERM VISION

Another transformative opportunity for the UK lies in the rapidly expanding global space economy, where the country has already established itself as a world leader across multiple domains. Bolstered by technological innovations and strategic investments – both public and private, the UK is poised to unlock new capabilities and skills in launch capabilities, satellite communications, surveillance and reconnaissance, position, navigation and timing (PNT), in-orbit services and manufacturing, among others.

Ensuring space exploration and operations are sustainable is a key focus, as it is across aerospace, defence and security. Efforts are underway to develop cleaner propulsion technologies for satellite launches and to tackle the escalating challenge of space debris.

ClearSpace, for instance, intends to do just that through its CLEAR Mission, funded under the UK Space Agency’s national debris removal programme. The company plans to deploy its novel robotic capture system to safely remove two obsolete, washing-machine-sized UK satellites from orbit. By leveraging advanced technologies to mitigate the risks posed by space debris to satellites and crewed space stations, ClearSpace aims to ensure cleaner, safer and more sustainable space orbits.

Space and sustainability are central themes for Farnborough International Airshow (FIA) 2024, alongside innovation, defence, skills and future flight. FIA provides a crucial platform to showcase the UK’s aerospace, defence, security and space capabilities to a global audience, and holds tremendous political importance. Even more so this year.

FIA 2024 is scheduled just two weeks after a general election, which could bring a change of government. This shift brings new uncertainty at a critical time. Recent government commitments indicate a growing intent to develop a new generation of aircraft, defence systems and space technologies, supporting thousands of high-skilled jobs nationwide.

The UK has untold opportunities to develop and expand its existing strengths, from additive manufacturing and lightweighting to decarbonisation and the use of quantum computers for threat mapping. Given the political instability the country has experienced of late, it’s imperative that the party in power acknowledges the international attention FIA receives and harnesses it to send a clear signal to industry and the global community that the UK takes these opportunities seriously.

Uncertainty and ambiguity often spook markets, notes ADS’ Aimie Stone, adding that while the UK may not match other nations in funding levels, it can surpass them with a clear, robust and long-term strategy. Reflecting on the past 10 years, the UK aerospace, defence, security and space sectors have made remarkable progress. Looking ahead to the next decade and beyond, the stage is set for the UK to build on these achievements. And the time to start is now.

Helical Motion

Helical Motion

The introduction of the ISCAR HELIMILL in the 1990s marked a significant milestone in milling tools. It changed the design of milling tools with indexable inserts, establishing a new approach that would help to shape the industry.

The breakthrough was achieved using a parallelogram-shaped carbide insert, featuring a helical cutting edge formed by the intersection of the insert’s helical side and shaped top surfaces (Fig. 1). The HELIMILL concept offers several advantages. Firstly, the consistency of the rake and relief angles along the insert’s cutting edge, when mounted on a tool reduces cutting force variations and ensures a smooth cutting action. Secondly, the uniformity of the insert’s cutting wedge enhances its strength. Lastly, the helical cutting edge’s proximity to the imaginary cylinder generated by a rotating tool improves accuracy compared to the straight edge found in previous-generation milling inserts. These advancements have elevated milling performance.