🎧MSC cut cycle times with new tooling

Longbridge-based DaceCrown Ltd has established itself as a leading supplier of precision components to the bottling and packaging industry. However, after 25 years of operation, a new generation of engineering talent has taken over and plans to elevate the company to new heights.

“Over the years, the company built a strong reputation among global brewing, beverage, and pharmaceutical brands for tackling the toughest packaging and handling challenges,” says Tom White, Co-owner at DaceCrown Ltd. Tom, whose background is in applications engineering and technical sales, purchased DaceCrown in 2023 with his business partner and Operations Director, Jake Harley-Arliss.

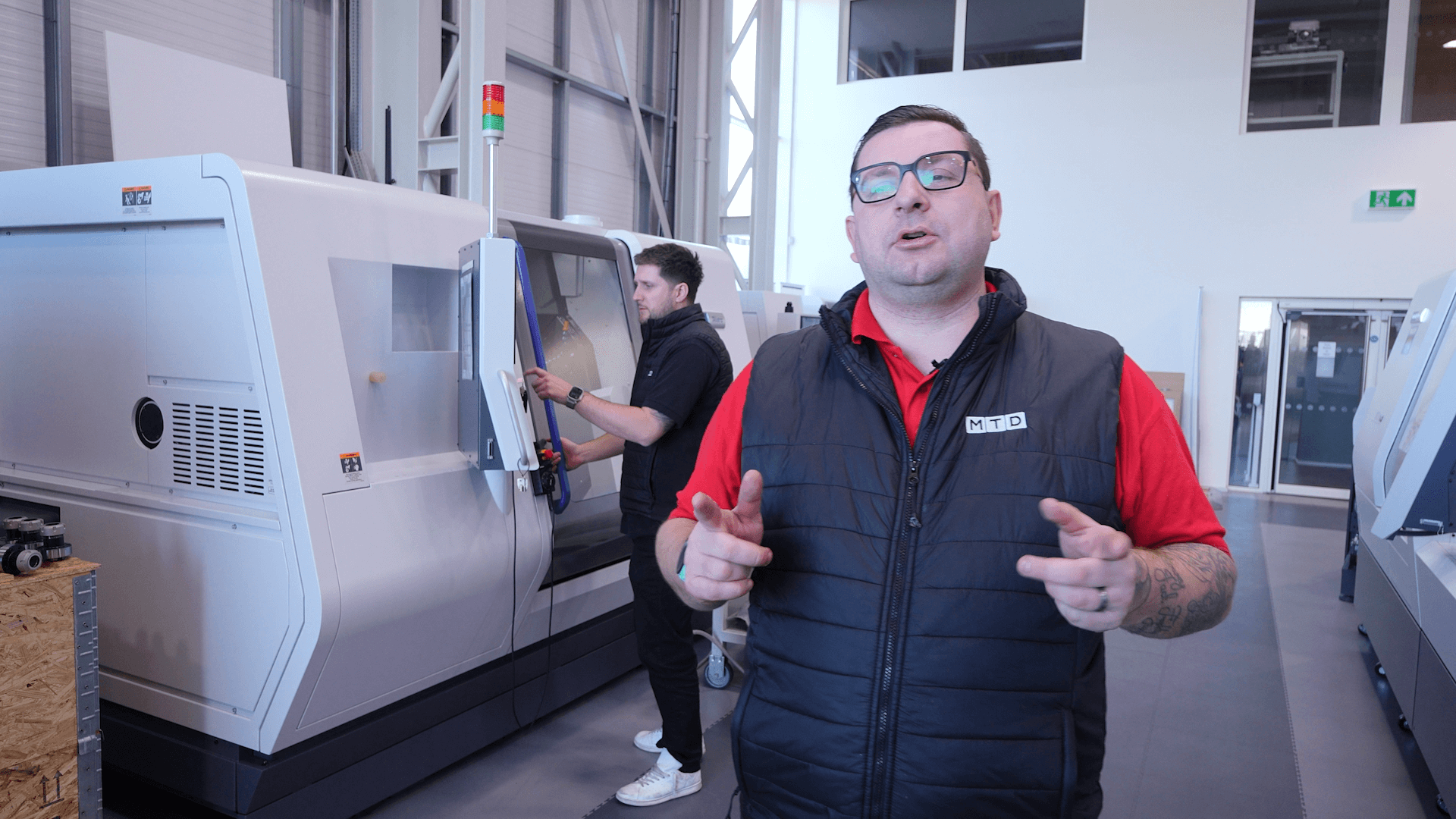

In less than a year, they transformed DaceCrown from a fully manual workshop into a facility with three HAAS machine tools: a VF-9 large-capacity VMC, a VF-2 VMC, and an ST10 high-performance turning centre.

“The previous owners primarily used manual lathes for production, a highly skilled but increasingly scarce method. Recognising the need to futureproof the business and expand the customer base, we made a strategic decision to transition to more modern production methods,” Tom explains.

“This change in approach very quickly opened the door to winning more jobs for high-value components with complex machining requirements, such as sharper tips, better corner radii and finer screw threads. You couldn’t do that work at scale on manual machines.”

However, as business grew, the DaceCrown team soon realised that the tooling on their HAAS machines was still potentially holding them back from reaching their true potential.

To help align the company’s tooling with its growth ambitions, DaceCrown turned to MSC Industrial Supply Co. UK. MSC application engineers visited DaceCrown over several weeks to immerse themselves in the business and gain firsthand experience of the tooling challenges facing Tom and his team.

The trials coincided with the testing stage of MSC’s newly launched MSC EDGE range of multipurpose solid carbide holemaking and milling tools. In turn, DaceCrown served as a vital field test site, providing important performance data to MSC throughout the testing process.

During the trial, a variety of materials and toolpaths were tested. Following its completion, DaceCrown was supplied with a set of 4, 8, and 12mm MSC EDGE endmills, which have enabled the team to handle a wide range of materials and applications without having to change tooling regularly.

“It was an instant game changer. We went from a 1 minute 50 second cycle time down to 10 seconds. It was a case of plug and play; put the tool in, set the speeds and feeds, and press go. We’ve used them on stainless steel, mild steel, structural steel, and aluminium. We can do pocket milling, milling into holes that were drilled too small, and we’ve also done some profiling work,” Tom adds.

“The best thing is, we can keep them in the tool magazine, which reduces our set-up times. And, even though we are running at higher speeds and feeds, we’ve found the MSC EDGE tooling to be very durable, so we don’t have to replace it as often as we used to with our previous supplier. This means we can not only complete jobs faster and turn around work for our customers quicker but also keep our own tooling costs down.”

“We’ve always strived to deliver the best possible quality for our customers. The parts we supply touch the end product last, so if we make a mistake, then the whole line can go down. Quality is everything for us and our customers; therefore, if it’s not right, it’s not leaving our facility,” Tom concludes, reassuring the audience about the company’s commitment to quality.