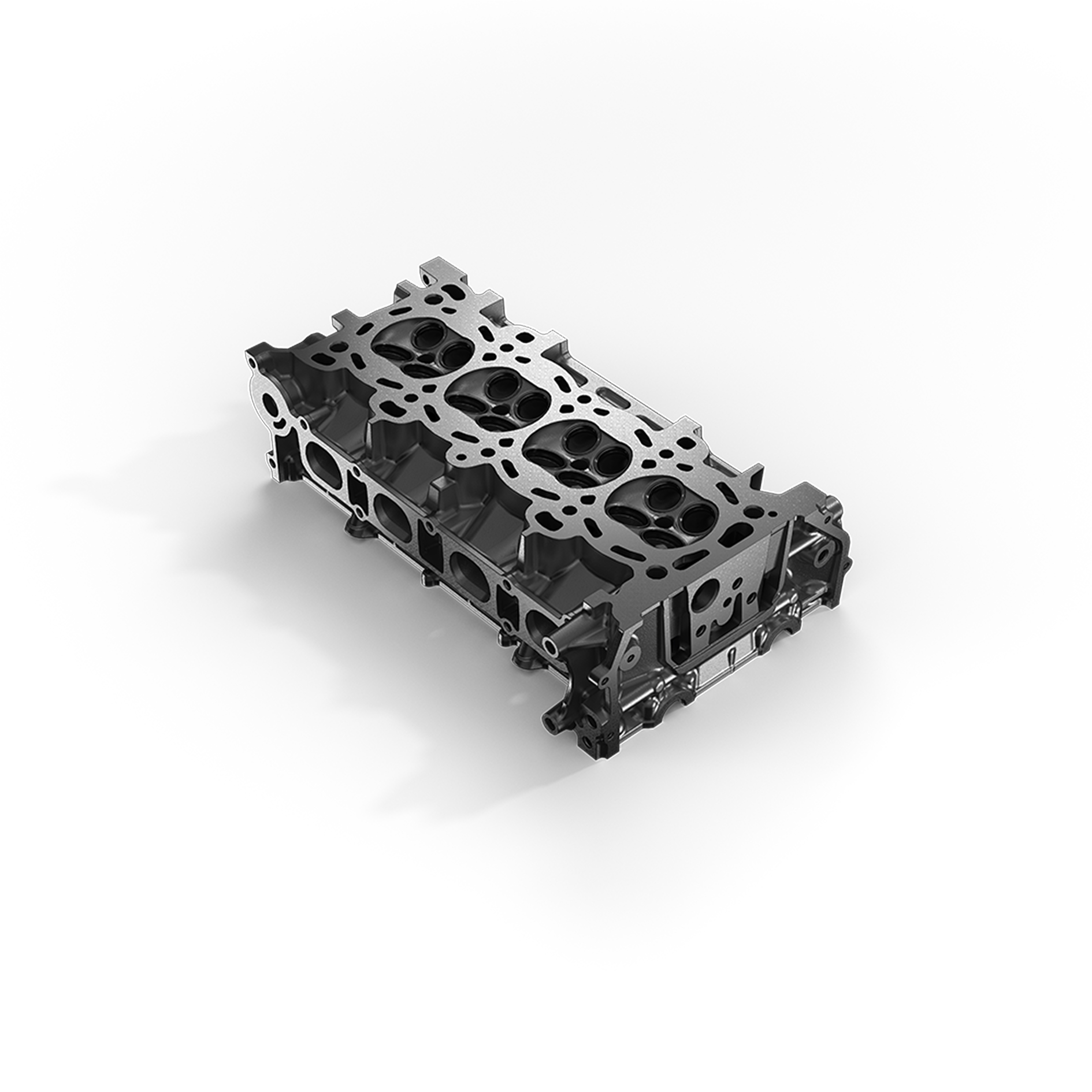

Ceratizit has developed a new tooling system for high-precision, cost-effective valve seat machining in the automotive sector. The solution will assist demanding cylinder head machining tasks and in particular valve seat machining.

Valve seat machining is known to place high demands on the precision of cutting tools with tight geometric and positional tolerances between the valve seat ring and valve guide as well as the narrow-angle tolerance of the sealing chamfer on the valve seat ring – all being challenges to meet. Add to this, the roundness specifications and diameter tolerance in the valve guide and the materials used in the valve seat ring and valve guide, and the demands on the cutting material and cutting edge geometry are a certain challenge. The new modular tooling system from Ceratizit, cost-effectively addresses these issues.

Valve seat machining is known to place high demands on the precision of cutting tools with tight geometric and positional tolerances between the valve seat ring and valve guide as well as the narrow-angle tolerance of the sealing chamfer on the valve seat ring – all being challenges to meet. Add to this, the roundness specifications and diameter tolerance in the valve guide and the materials used in the valve seat ring and valve guide, and the demands on the cutting material and cutting edge geometry are a certain challenge. The new modular tooling system from Ceratizit, cost-effectively addresses these issues.

The new valve seat tooling system consists of two similarly structured multi-functional tools. One is for the semi-finishing of the intake and exhaust and consists of a pilot reamer for the valve guide and cutting edges for the valve ring. The second tool for finish machining of the intake and exhaust incorporates a finish reamer and finish cutting edge for the sealing chamfer on the valve ring.

Each tool is a modular design that features standard and semi-standard components and ensures short delivery times. The system consists of a hydraulic double chuck with a (DAH) compensation holder that can be used to compensate for runout and angle errors directly on the machine. Additionally, the system can be equipped with a choice of popular spindle connections, such as HSK, ISO, MAS-BT, CAT and HSK-A63. A blade carrier with fixed insert seats and three-edged CBN full-face indexable inserts also forms part of the system. A six-edged solid carbide or PCD reamer is used to machine the valve guide and the hydraulic double clamping of the reamer and blade carrier ensures high-quality process-secure machining results.

Ease of handling is also a key feature. This highly precise and specialised machining process requires no adjustment and the result is a reduced scrap and rework rate. The versatility of the modular design also assists in lowering tooling costs as, if any design changes are made to the valve seat ring, the entire tool does not have to be replaced. Simply replacing the blade carrier is sufficient. This only incurs roughly a third of the total costs. This also offers a cost advantage for follow-up projects because even if new reamers and blade carriers have to be procured for a new cylinder head, the hydraulic double chucks can be reused.

Ease of handling is also a key feature. This highly precise and specialised machining process requires no adjustment and the result is a reduced scrap and rework rate. The versatility of the modular design also assists in lowering tooling costs as, if any design changes are made to the valve seat ring, the entire tool does not have to be replaced. Simply replacing the blade carrier is sufficient. This only incurs roughly a third of the total costs. This also offers a cost advantage for follow-up projects because even if new reamers and blade carriers have to be procured for a new cylinder head, the hydraulic double chucks can be reused.

Statement from Matthias Otto, project manager and visionary behind the new development:

“From previous experience of tool management in the automotive industry, the adjustment of valve seat tools has always been a necessary evil that is time-consuming and error-prone. After all, where something needs to be adjusted, there is potential for error. For this reason, I aimed to develop a tool system with fixed insert seats that do not require any adjustment.”

“The modular design consists of a hydraulic double chuck, exchangeable blade carrier and the reamer. This offers additional benefits, such as cost and time savings in project management with maximum precision in the tool system through the plug & play solution. The concept of using as many of the same components as possible on the tools for intake and exhaust has also been made a reality.”

“The modular design consists of a hydraulic double chuck, exchangeable blade carrier and the reamer. This offers additional benefits, such as cost and time savings in project management with maximum precision in the tool system through the plug & play solution. The concept of using as many of the same components as possible on the tools for intake and exhaust has also been made a reality.”