Contracts Engineering Limited (CEL), one of Southeast’s largest contract manufacturers, has set a bold target of becoming one of the largest in the UK by 2028. To achieve this ambitious goal, the company is investing heavily in automation, including the use of robots and cobots. Here, Managing Director Troy Barratt explains the company’s journey of going from no robots to 1 – as going from 0 to 1 is the biggest leap! The company now has a robot and a cobot and is taking steps to scale up robotics and automation integration after recognising the impact it is having upon the business.

The Critical Role of Robotics at CEL

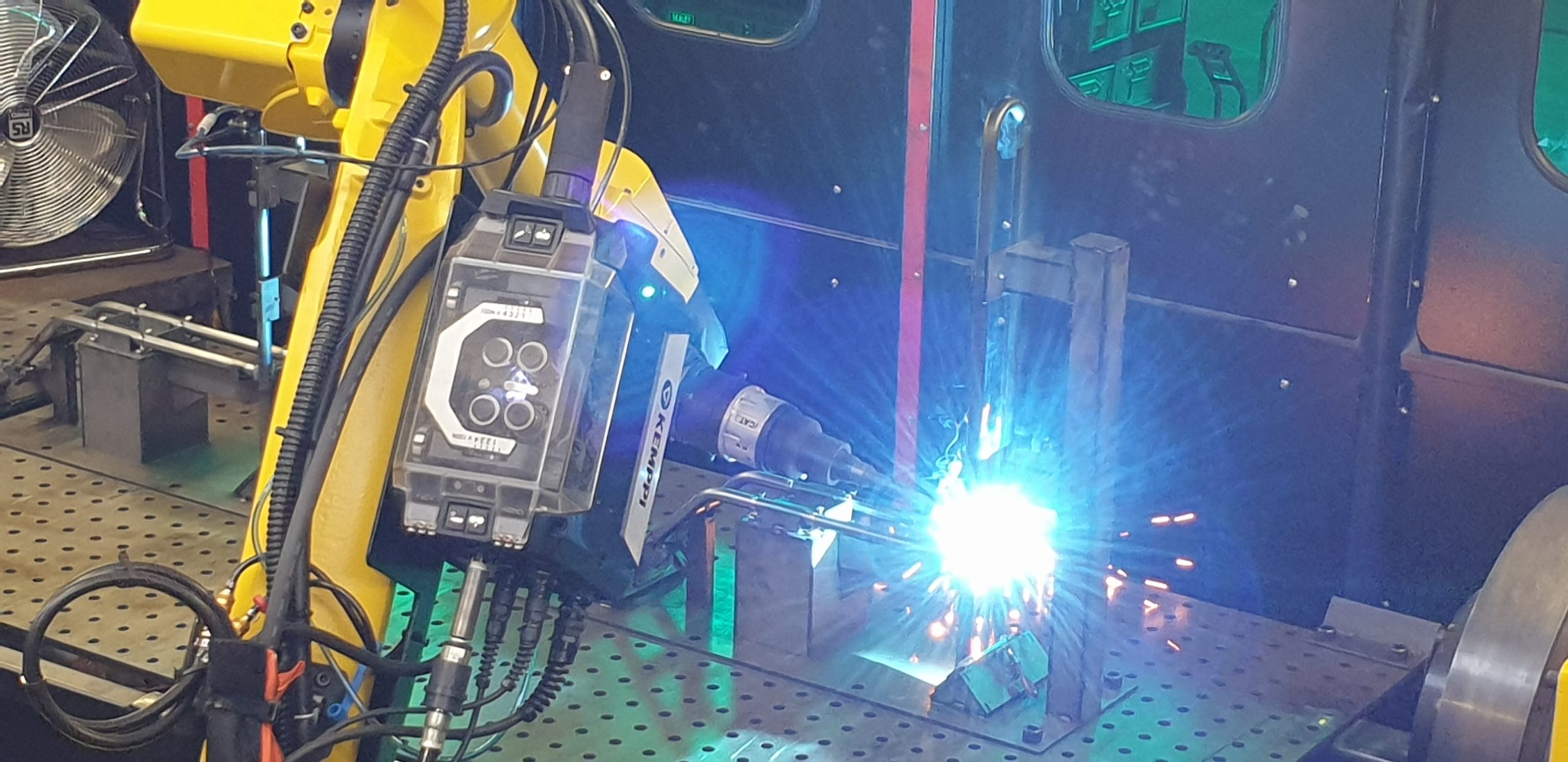

We recognised the importance of incorporating industrial MIG welding robots into our production in 2018 when we started to struggle with high volumes of repetitive welded assemblies. However, before implementing these technological solutions, we first needed to address our internal concerns. These included getting positive engagement from staff, picking the leaders for day-to-day integration and how to integrate the robot into our existing ERP production planning system.

To get the team engaged, we reframed the discussion from ‘robots take jobs’ to ‘our robot creates jobs and increases productivity’. Put simply, the robot generates a lot of additional work in other parts of our factory, and by increasing productivity within the welding department, we can upskill and increase pay. The reframing turned the investment into a win for everyone.

Getting strong positive engagement made it fairly easy to pick the team leads, as a lot of folks wanted to be involved. The team leads then took the reins to integrate the robot into our existing ERP. We focused on these areas early so that we had the right foundation to start speaking with potential partners.

Finding the Ideal Partner for Industrial MIG Robots

Our journey to acquire an industrial MIG robot focused on finding a reliable system integration partner, not simply buying a robot. We sought a supplier that could design the right system, provide training, and critically would offer strong after-sales support.

After evaluating four or five system integrators and assessing their offerings, CEL chose a partner that best understood their needs and provided excellent aftermarket support. The winner won out on the services they offered, not price. Price matters, but the right partner matters more!

Learning and Growing with Robotics: Overcoming the Learning Curve

We took time to integrate the robot into all areas of the business and make course corrections as needed. Our guiding principle is ‘Start slow, then go fast.’ This emphasises the importance of building a solid foundation to avoid the common ‘one and done’ syndrome. By investing time and resources in the initial stages of robot integration, we ensured a smoother transition to our second robot investment.

Depending on the parts, the cobot either fully welds a partially-welded assembly, or it completes all welding. Our cobot welds alongside a fabricator, which more than doubles the fabricator’s hourly production rates. In addition to doubling output, the cobot also ensures a consistent level of welding across the production run. By the time we were ready to think about our next robotic investment, we had a healthy list of areas that would benefit, allowing us to move at greater speed when identifying our second robot.

The Next Step: Buy a Cobot to Cover the Middle Ground

A couple years’ of learning and experience allowed us to identify opportunities for future automation, particularly collaborative robots (cobots). These cobots excel in medium volume work and assist fabricators in producing high-quality welds, ultimately increasing efficiency and productivity. Each cobot roughly doubles the productivity of a fabricator.

Cobots generally require a lower investment point because you do not need to invest in the ‘system’ surrounding the robot. We could move our medium batch work to a cobot, and the lower price point would allow for a quicker payback than with our industrial robot.

A Technological Leap: Click-and-Drag Programming for Enhanced Accessibility

A recent breakthrough in cobot technology is the transition from lines of code-based programming to a more intuitive click-and-drag interface. This development has made programming accessible to a broader range of team members, fostering quicker and greater upskilling.

In Conclusion: A Quote from a Great Industrialist

Cobots enable us to increase our production volumes and upskill our team. They are a ‘win-win’ combination for us, and for any manufacturing company that is scaling up. As we increase our knowledge-base, the robots and cobots we have are part of a clear plan to integrate more of them around our factory.

Over 100 years ago Henry Ford, one of the world’s greatest industrialists, said: “If you need a machine and don’t buy it, then you will ultimately find that you have paid for it and don’t have it.”

This still holds true today, so start the journey now!