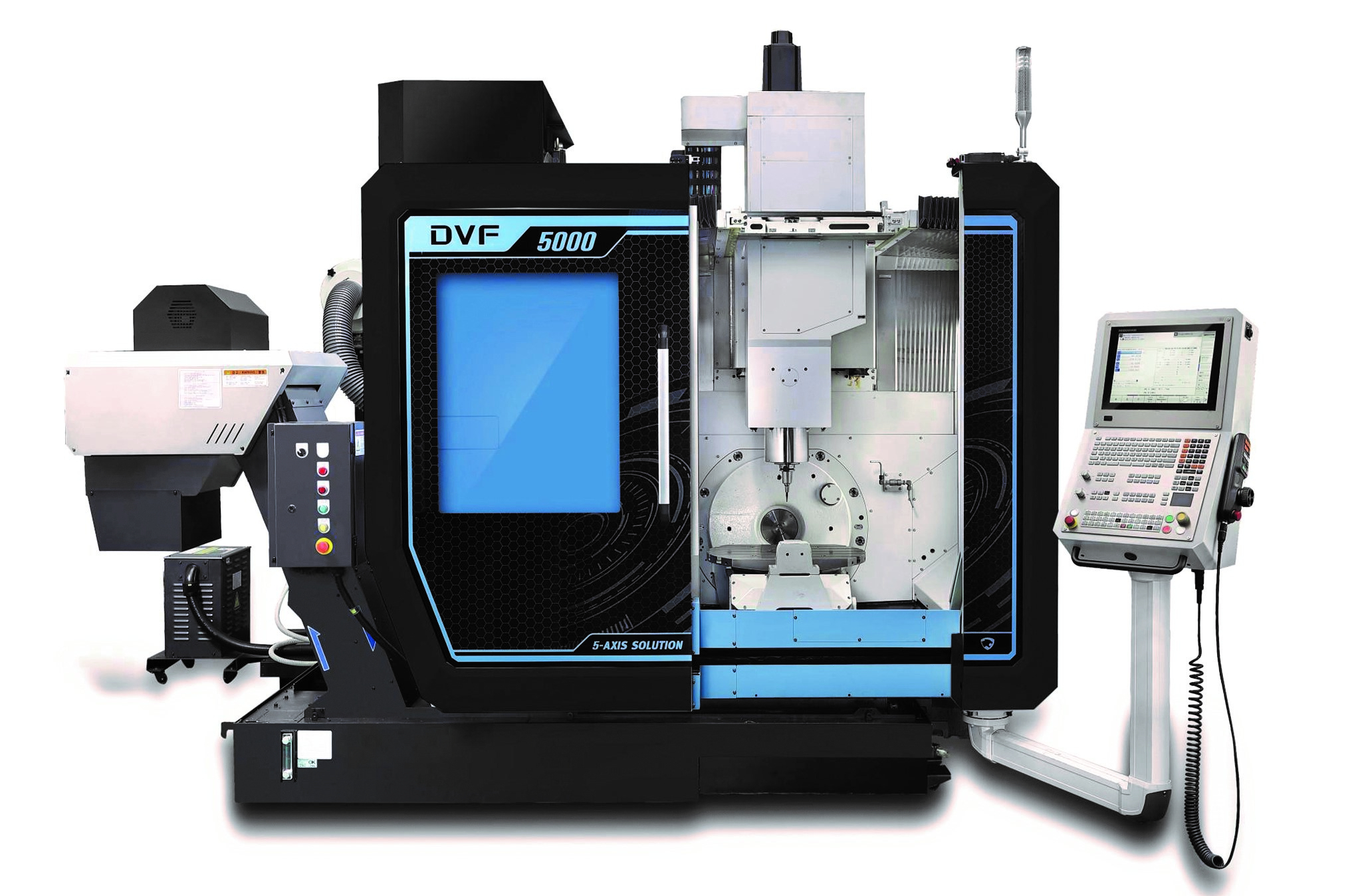

DN Solutions is set to showcase its latest innovation, the DVF 5000 Second Generation, at the International Manufacturing Technology Show (IMTS) 2024. This new model is an advanced simultaneous 5-axis vertical machining center designed for machining complex parts with high precision and efficiency.

Key Features and Enhancements:

- Larger Work Envelope and Table: The DVF 5000 Second Generation features a larger table size (Ø630 x 450 mm) and an increased work envelope, allowing for the machining of parts up to Ø600 x H500 mm. This represents a 26% increase in table size and a 32% expansion in the maximum machining area compared to its predecessor (EV Design & Manufacturing) (Metalworking EMEA).

- Enhanced Speed and Precision: The machine boasts significantly faster X, Y, and Z-axis feed rates, which are double the speed of the previous model. The B- and C-axis rotation speeds have also increased by 25%, now reaching 25 r/min. With a tool-to-tool time of 1.3 seconds and a chip-to-chip time of 3.8 seconds, the DVF 5000 Second Generation is 28% faster overall (EV Design & Manufacturing) (Metalworking EMEA).

- Advanced Spindle Options: The standard 20,000 r/min spindle and optional high-torque spindle (up to 230 Nm) enable the machining of a wide range of materials, including high-speed aluminum, titanium, Inconel, and Cobalt Chromium (CoCr). These features support high-precision and high-speed operations (EV Design & Manufacturing) (Metalworking EMEA).

- Thermal Stability and Compensation: The DVF 5000 incorporates multiple cooling units and smart thermal displacement compensation, ensuring high precision even during extended machining sessions. Active sensors monitor thermal displacement and adjust to minimize expansion and distortion (Metalworking EMEA).

- Automation and User Convenience: The machine supports seamless integration with automation units for material loading and unloading. It includes a 120-tool magazine and features compact automation systems like AWC (Automatic Work Changer), enhancing operational efficiency and flexibility for unmanned operations (EV Design & Manufacturing) (Metalworking EMEA).

- Flexible Control Options: Users can choose between FANUC, HEIDENHAIN, and SIEMENS controls, all equipped with advanced technology to enhance data processing speeds and machine setup. The FANUC control, in particular, includes a collision prevention system that actively monitors and prevents potential collisions (EV Design & Manufacturing) (Metalworking EMEA).

Visit DN Solutions at IMTS 2024: To see the DVF 5000 Second Generation in action, visit DN Solutions at Booth #338900 during IMTS 2024, held from September 9-14 in Chicago