Anyone that builds, repairs or refurbishes machine tools will know that ballscrew lead times are getting longer and longer. Most people are visibly shocked when they hare told a new ground ballscrew that before Christmas had a manufacturing lead time of around 6-8 weeks is now taking 18-20 weeks – and that’s just for standard stock. Purchasing unusual or bespoke ballscrews is taking even longer with delivery dates already deep into 2019. MTD Magazine spoke to ballscrew experts PGM Reball to find out more..

Lead times for lower precision rolled ballscrews have also suffered in a similar way; however these lengthy lead times have lagged a little behind that of ground ballscrews. Rolled ballscrews are easier and cheaper to manufacture and stockists are more likely to have stock. It is only when stock is depleted that lead time issues will surface. Generally, its only machine tool OEMs and niche ballscrew specialists that keep bespoke ground ballscrews in stock that are likely to have ground ballscrews available. However, even these OEMs are quoting longer and longer lead times for replacements.

For machine and machine tool builders there is huge anxiety as they find it difficult to meet order deadlines. Manufacturers suffer the double whammy of also trying to source available linear guides, something also suffering from extended lead times. With all the major brands quoting impossible lead times – and in some cases refusing to quote at all – buyers and engineers are turning to smaller niche players and looking further afield to try to source ballscrews and linear guides within acceptable lead times.

So, what’s happened to cause the disruption?

Well, the answer is never simple. It seems to be the result of a number of converging pressures across the world that all impacted around the turn of the year.

Firstly, there are pressures such as steel availability. The demand for steel is forecast to grow by 4.5% in 2018 and by around 4.9% in 2019 in the emerging and developing markets. Even in developed markets, growth is around 1.8% so there is a huge squeeze on the supply of raw material.

Secondly, there has been a sustained upswing in global growth from China, the Eurozone and the US. This has put pressure on the major ballscrew and linear guide manufacturers. Production capacity became full very quickly and manufacturers have struggled to increase capacity to meet the new demand. Ballscrews and linear guides have become more difficult to source within acceptable lead times. This means any spare stock is gobbled-up as manufacturers stock up on critical spares.

Lastly, for us in the UK there is also a Brexit effect. The fall in the value of the Pound and a more buoyant global demand for goods has shifted the economy towards stronger export growth rather than domestic growth. Anecdotally, we have also seen examples amongst UK suppliers that their European manufacturers are preparing for a no-deal Brexit by stockpiling critical, hard to source, niche or unique items that are likely to impact production, if no trade deal with the EU is achieved.

At the moment there’s a big melting pot of pressures bubbling away whilst we wait for capacity to increase for us all to get back to normality – but we can’t see the situation changing anytime soon. Ballscrews are a complex business and the barriers to entry are quite high. It’s difficult and costly to increase capacity and given that it’s taken nearly 10 years for the world economy to finally recover from the ravages of the 2008 financial crisis, one can understand why investors are reluctant to invest in additional capacity.

So, what should be your coping strategy?

We have 3 ways you can cope with the delays that longer lead times can cause:

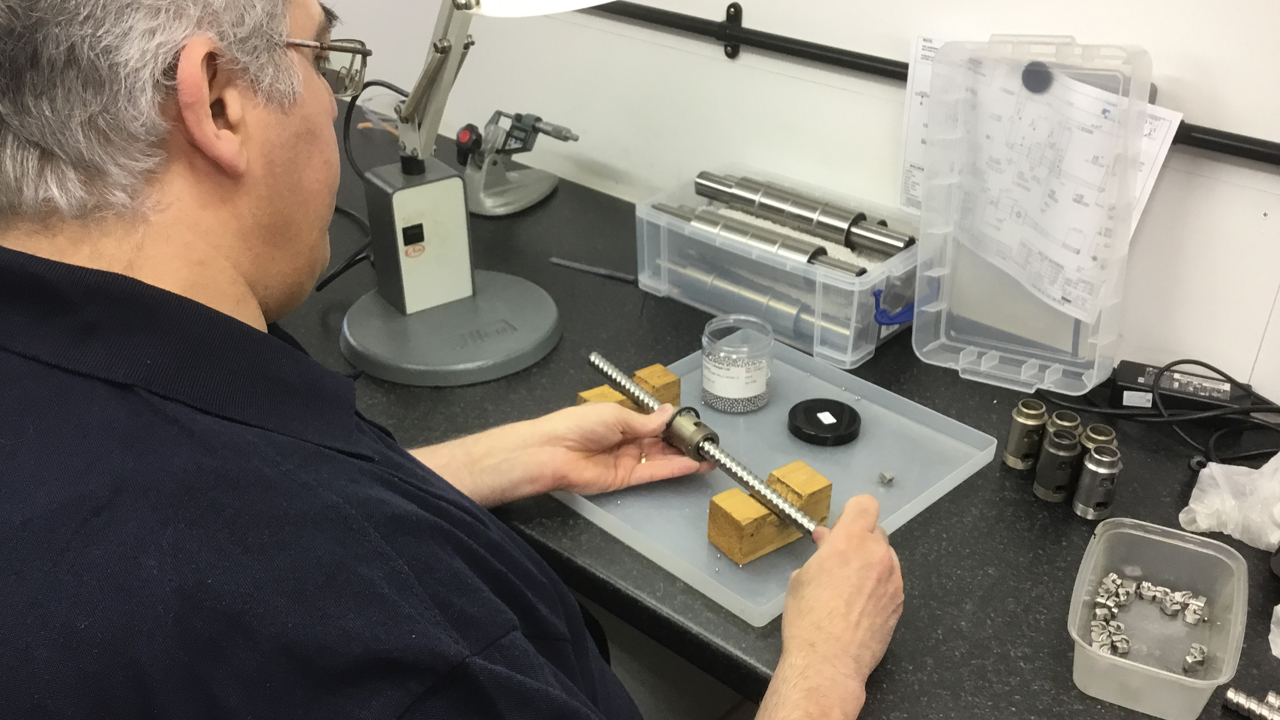

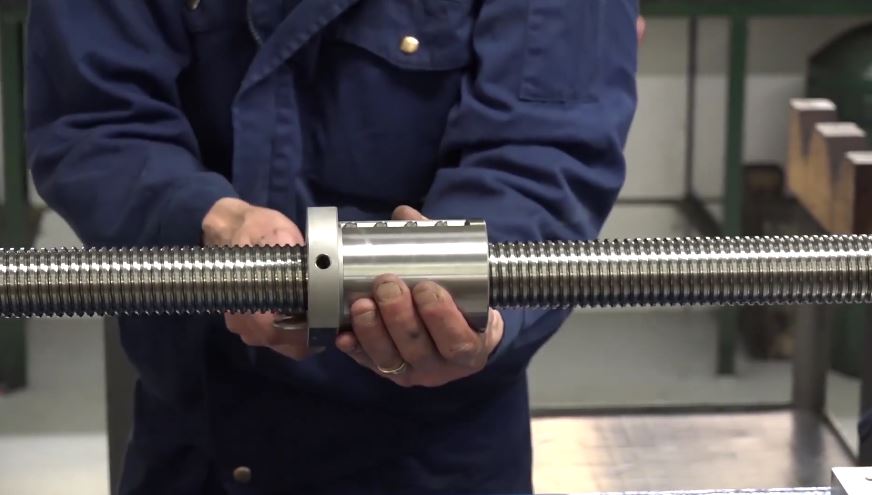

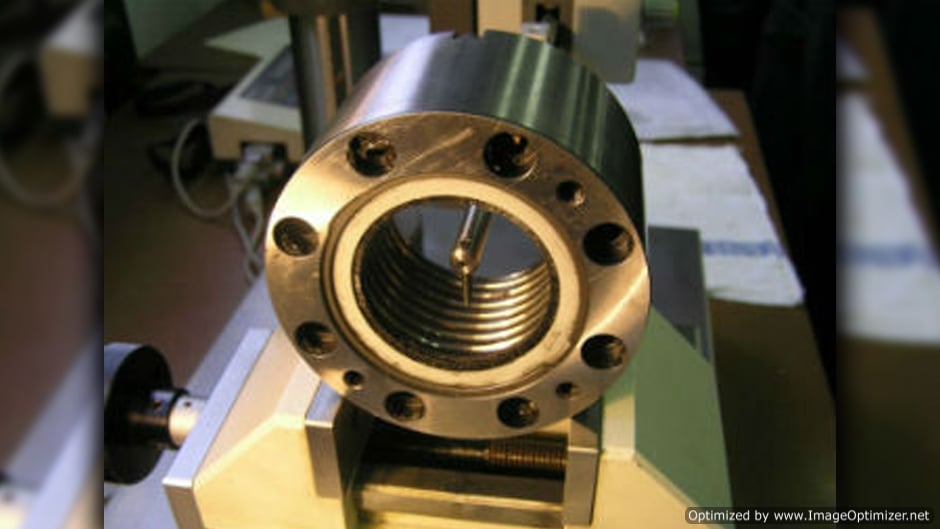

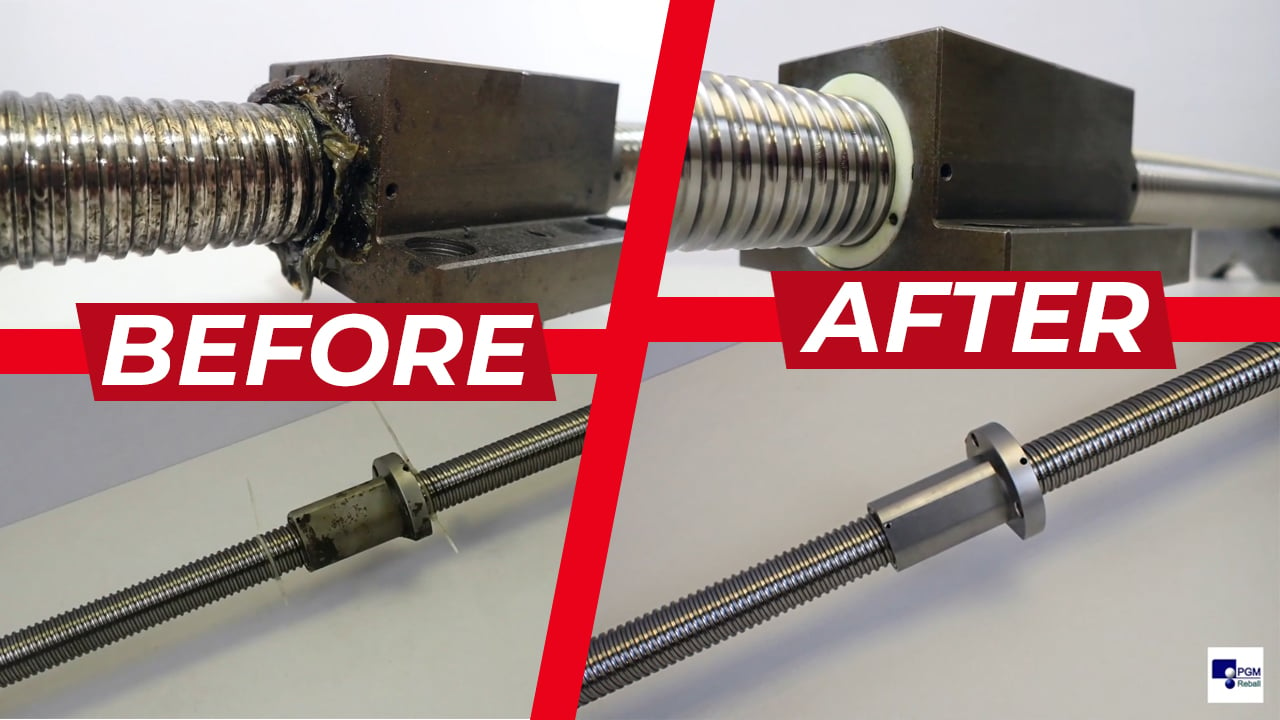

Repair – If you are a manufacturer looking to repair, maintain or refurbish existing machinery, then a ballscrew or linear guide repair is always a good option. Turnaround times are quick, often as fast as 24-48 hours and the end result is normally a ballscrew that performs to an ‘as new’ standard.

Maintain – it is now more important than ever to nurture your ballscrew and linear guides and value them for the scarce commodity they are. Oil or grease them well and service them regularly with a ballscrew refurbishment specialist. It is better to lose one or two days production than wait 6 months for a replacement.

Stock up – If you have critical machinery then you need to buy a spare. Ordering a spare ballscrew or linear guide now means you will not have to wait when you really need it.

Unfortunately, for machine and machine tool builders there is very little that can be done, but you do need to source your ballscrew and linear guide requirements as soon as you can – a good 6 months before you need them. Also, look further afield to ballscrew specialists rather than usual distributors. Ultimately though, you need to plan well ahead to ensure you have your ballscrews and linear guides when you need them.

PGM Reball Ltd are ballscrew experts specialising in repair, sales and manufacture of ballscrews. With an international reputation in their field, PGM Reball can source hard to find ballscrews and linear guides using extensive global networks.