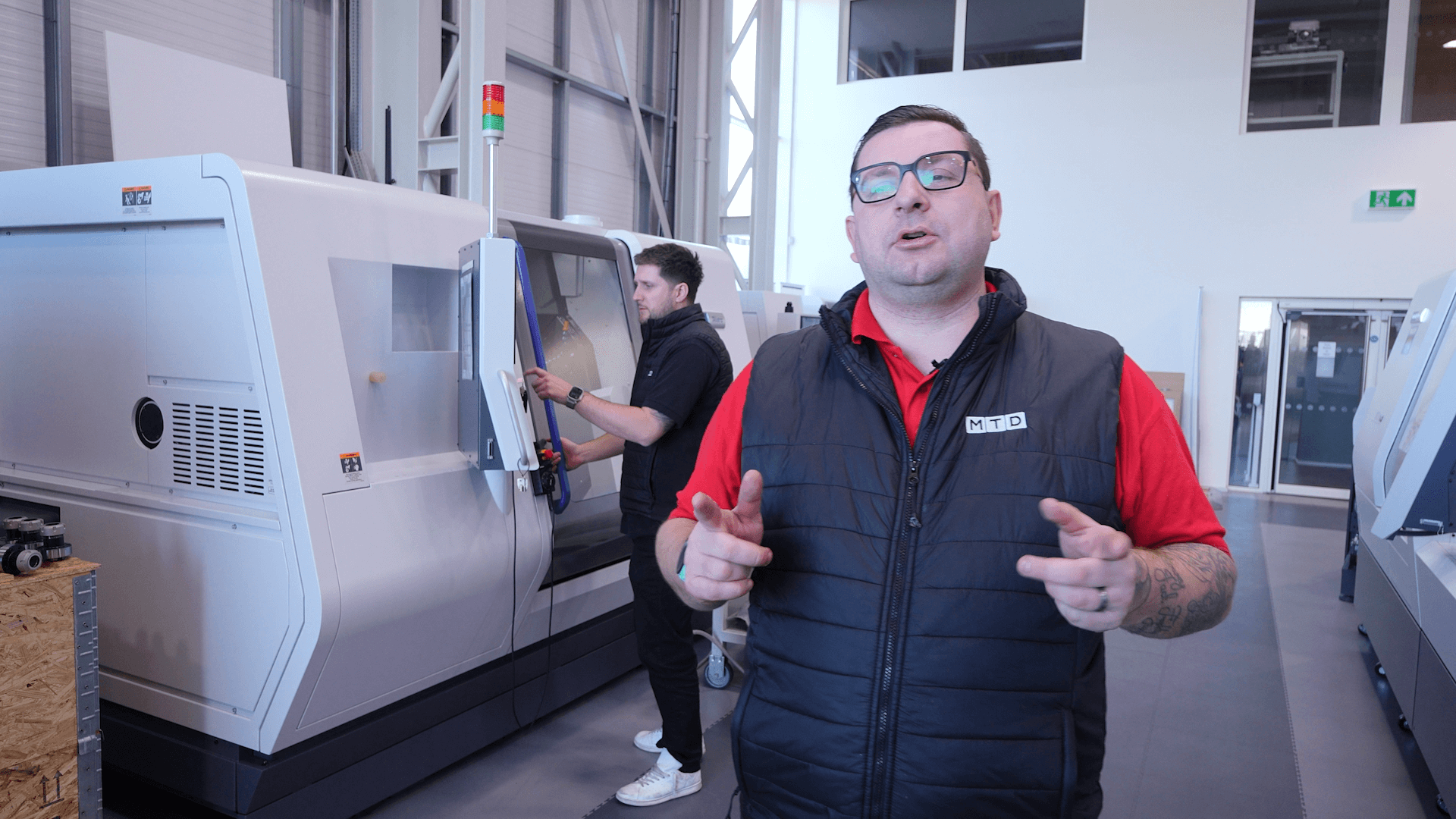

Hope Technology Expands CNC Capabilities with Latest Citizen Cincom Installations

Hope Technology has bolstered its small-parts turning section with the installation of two more Citizen Cincom sliding-head lathes, reinforcing a long-standing partnership with Citizen Machinery UK. The new Cincom A20-VIILFV, delivered in September 2024, and the L12-VIILFV, added in May 2025, mark the eighth and ninth sliding-head lathes purchased by the British manufacturer since 2004. These latest investments support the company’s continued growth and high-volume output, especially in the production of bicycle aftermarket components.

Based in Barnoldswick, Lancashire, Hope Technology employs around 150 people and exports half its production to more than 40 countries. Founded in 1989 by former Rolls-Royce aero engineers Ian Weatherill and the late Simon Sharp, the company has built a reputation for precision, quality, and self-sufficiency—machining, heat treating, anodising, and assembling all parts in-house from high-grade materials including aluminium, stainless steel, brass, and carbon fibre.

High-Volume Output Drives Machine Investment

“The driving force behind new machine purchases is the sheer volume of orders,” says Lindley Pate, Hope’s long-serving works and production manager. “The speed and productivity of the Citizen lathes, especially the Cincom A20s, are perfectly suited to our batch sizes and production targets.”

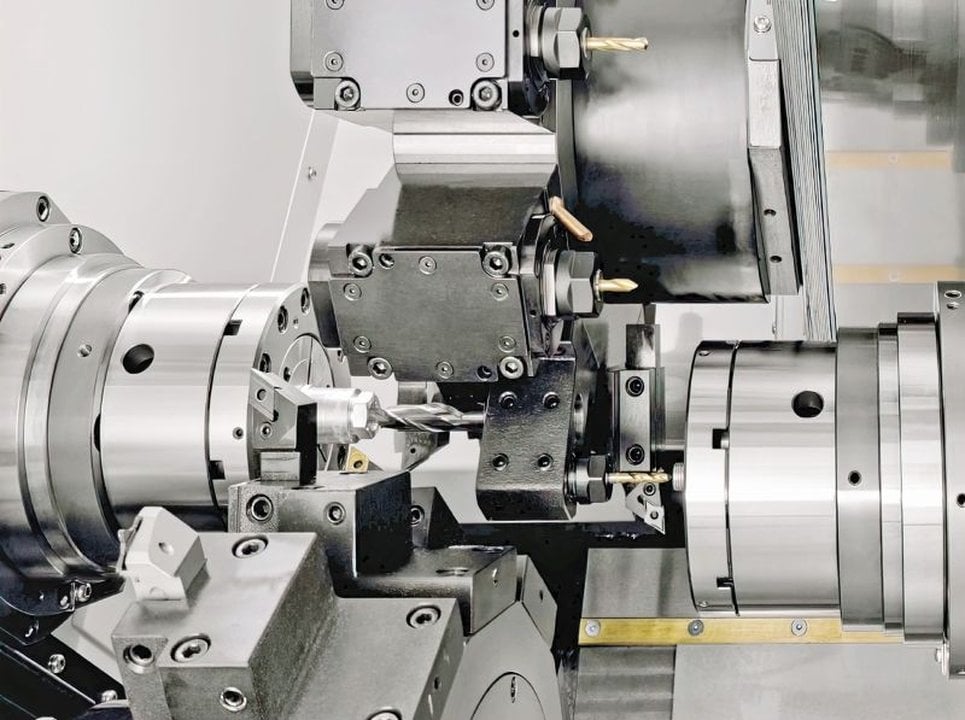

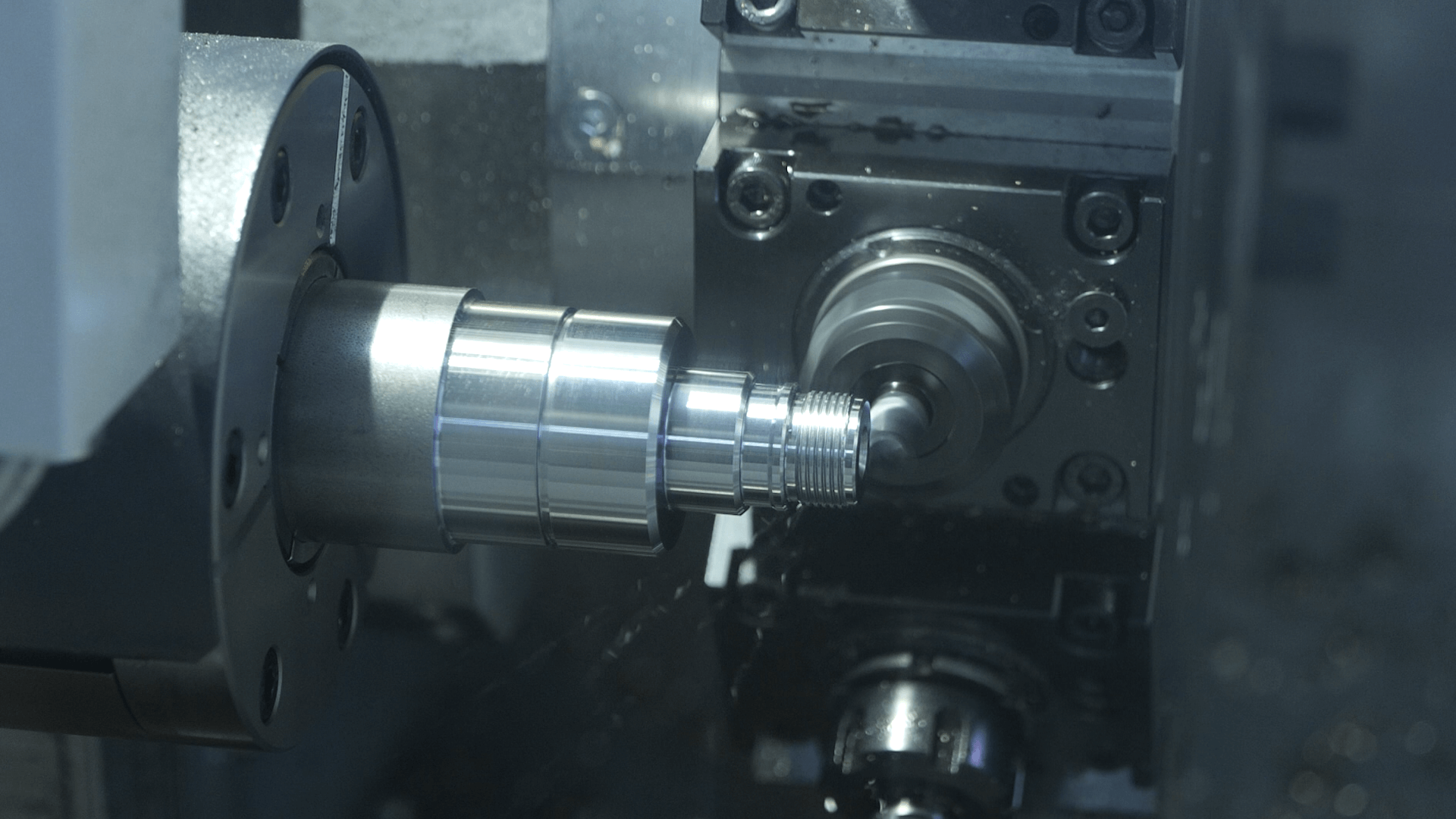

Hope currently operates more than 70 CNC machine tools, including a full complement of six 20mm Cincom models, alongside a 16mm, 32mm, and now a 12mm machine. The company also uses seven Citizen Miyano fixed-head lathes, with bar capacities up to 65mm. These machines handle a wide range of turned parts, including a lightweight aluminium rear cassette lockring, which is now produced in significantly reduced cycle times on the Miyano platform.

Smarter Chip Control and Material Efficiency

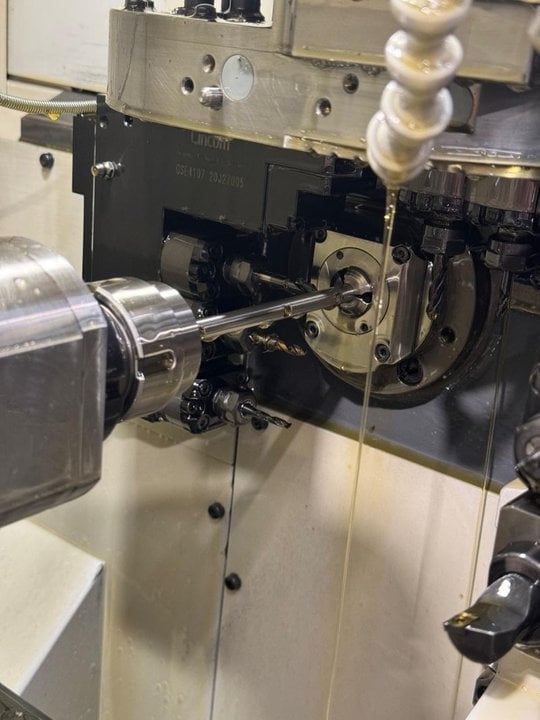

Key to the success of Hope’s latest sliding-head acquisitions is Citizen’s Low Frequency Vibration (LFV) technology. Integrated into the Fanuc-based control systems, LFV ensures clean chip breaking by intermittently lifting the tool away from the workpiece during the cutting cycle. This produces small, manageable chips rather than continuous ribbons of swarf, which can entangle components, halt production, or cause damage.

The LFV functionality, especially on aluminium parts, supports extended lights-out machining by preventing swarf buildup. To maximise unattended running, Hope has also decided to retrofit swarf conveyors to both new A20s.

In addition, Hope plans to begin utilising the guide bush removal feature on its Cincom machines—a strategy that can cut material costs significantly. “By removing the guide bush when machining short parts, we can switch to less expensive extruded bar and reduce material waste,” says small-parts turning supervisor Andy Savage.

Software Support Streamlines Programming

Hope Technology’s programming team makes extensive use of Citizen Machinery’s Alkart Wizard software, which simplifies CNC programming across both Cincom and Miyano platforms. The software provides a guided interface, reusable code snippets, and graphical diagrams that reduce errors and speed up the creation of new part programs—ideal for a fast-paced production environment.

“Tolerances on most of our parts are relatively open,” adds Mr Pate, “but on critical features like bearing diameters, we need to hold +0.01mm. The Citizen lathes achieve this with ease. Their reliability and performance have kept us coming back for over two decades.”

As demand continues to grow, Hope Technology remains committed to investing in cutting-edge machining technology, ensuring its ability to meet global orders with the quality and speed customers expect.