Mercedes-Benz Expands Luxury Presence with New Showrooms in Agra and Faridabad, Reinforcing Commitment to Emerging Markets!

Mercedes-Benz India has officially unveiled new luxury facilities in Agra and Faridabad, marking a significant expansion…

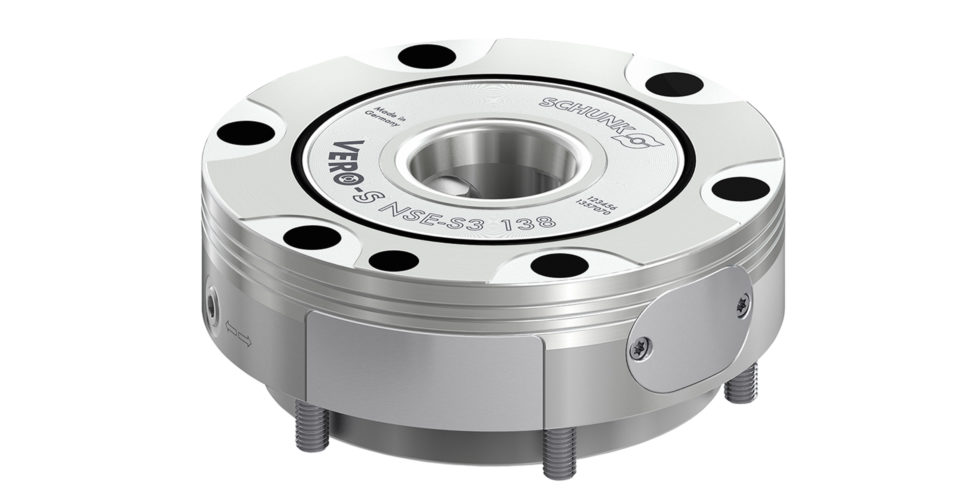

Clamping Technology

In the course of digitalization in production, the trend is towards fully automated, fully networked, and autonomously acting manufacturing systems. Of course, this trend has an influence on clamping technology: the VERO-S NSE-S3 138 sees SCHUNK present for the first time a sensory quick-change pallet module that allows permanent monitoring of the pull-down force and the clamping slide position. Moreover, the presence of the workpieces, or clamping pallets can be monitored. Strain gauges, measuring amplifiers, and inductive sensors are directly integrated in the module, and the module has the same dimensions as the conventional clamping module VERO-S NSE3. The sensory quick-change pallet module creates the prerequisites for a consistent real-time analysis of the clamping situation, and provides important parameters for process optimization. The voltage supply (24 V DC) and signal output (analog 0-10 V DC, digital 0/24 V DC) is reliable and straightforward via spring contacts.

Be first to see all the updates from MTDCNC

Our newsletters frequency varies dependant on content

All the latest deals from the industry feature on our newsletters